Preparation method of high specific surface area porous carbon doped iridium catalyst for water electrolysis for generating hydrogen

A high specific surface area, porous carbon technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of interpenetration, large particle size, long reaction period and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Take 10g of 5A dehydration molecular sieves and sinter at 400°C for 12 hours, then add 500mL of N,N-dimethylformamide (DMF) solvent to dewater for 24 hours before use.

[0027] 2. Take 0.8939g zinc nitrate hexahydrate [Zn(NO 3 ) 2 ·6H 2 O] and 1.8913g trimesic acid (H 3 BDC) was dissolved in 80 mL of N,N-dimethylformamide (DMF), then 0.0111 g of polyvinylpyrrolidone (PVP) was added, stirred vigorously to dissolve, and 6 µL of hydrogen peroxide (H 2 o 2 , 30%), after stirring slowly, the precursor solution was obtained.

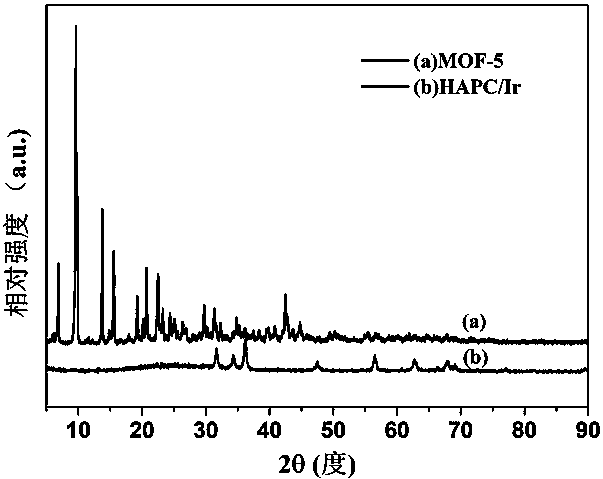

[0028] 3. Heat the precursor solution obtained in 2 in a 100ml autoclave at 100°C for 5 hours to obtain white MOF-5 crystals. See attached figure 1 , figure 1 a is the XRD pattern of MOF-5, the abscissa is the diffraction angle 2θ, the unit is degree (°), and the ordinate is the diffraction intensity. Typical MOF-5 characteristic peaks can be seen in the figure; see the attached figure 2 , figure 2 This is the scanning electron microscope ...

Embodiment 2

[0038] 1. Take 10g of 5A dewatering molecular sieves and sinter at 400°C for 12 hours, then add 500mL of N-methylpyrrolidone (NMP) solvent to dewater for 24 hours before use.

[0039] 2. Take 0.8939g zinc nitrate hexahydrate [Zn(NO 3 ) 2 ·6H 2 O] and 1.8913g trimesic acid (H 3 BDC) was dissolved in 80mL of NMP solvent, then added 0.0111g polyvinylpyrrolidone (PVP), stirred vigorously to dissolve, and slowly added 6µL hydrogen peroxide (H 2 o 2 , 30%), stirred slowly and fully dissolved to obtain the precursor solution.

[0040] 3. Heat the precursor solution obtained in 2 in a 100ml autoclave at 140°C for 5 hours to obtain white MOF-5 crystals.

[0041] 4. Get 2g of MOF-5 prepared in 3 and iridium chloride (IrCl 3 ) 2g was added into 100ml of NMP solvent and soaked for 48 hours, washed with corresponding solvent after centrifugation, repeated 3 times, and vacuum dried at 150°C for 2 hours to obtain HAPC / Ir precursor.

[0042] 5. The dried HAPC / Ir precursor in 4 was sint...

Embodiment 3

[0050] 1. Take 10g of 5A dewatering molecular sieves and sinter at 400°C for 12 hours, then add 500mL of N,N-diethylacetamide (DEF) solution to dewater for 24 hours before use.

[0051] 2. Take 0.8939g zinc nitrate hexahydrate [Zn(NO 3 ) 2 ·6H 2 O] and 1.8913g trimesic acid (H 3 BDC) was dissolved in 180mL of DEF, then 0.0111g of polyvinylpyrrolidone (PVP) was added, stirred vigorously to dissolve, and 120µL of hydrogen peroxide (H 2 o 2 , 30%) and stirred slowly to obtain the precursor solution.

[0052] 3. Heat the precursor solution obtained in 2 in a 200ml autoclave at 140°C for 24 hours to obtain white MOF-5 crystals. MOF-5 was tested by X-ray diffraction (XRD), the abscissa is the diffraction angle 2θ, the unit is degree (°), and the ordinate is the diffraction intensity; typical MOF-5 characteristic peaks can be seen in the XRD diagram; MOF-5 In the scanning electron microscope image, smooth cubic particles can be seen, the particle size is about 8 μm, and the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com