A kind of preparation method of high specific surface area porous carbon doped iridium electrolysis water oxygen evolution catalyst

A high specific surface area, porous carbon technology, applied in electrolytic components, electrolytic process, electrodes, etc., can solve the problems of large particle size, interpenetration, long reaction cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Take 10g of 5A dehydration molecular sieves and sinter at 400°C for 12 hours, then add 500mL of N,N-dimethylformamide (DMF) solvent to dewater for 24 hours before use.

[0027] 2. Take 0.8939g zinc nitrate hexahydrate [Zn(NO 3 ) 2 ·6H 2 O] and 1.8913g trimesic acid (H 3 BDC) was dissolved in 80 mL of N,N-dimethylformamide (DMF), then 0.0111 g of polyvinylpyrrolidone (PVP) was added, stirred vigorously to dissolve, and 6 µL of hydrogen peroxide (H 2 o 2 , 30%), after stirring slowly, the precursor solution was obtained.

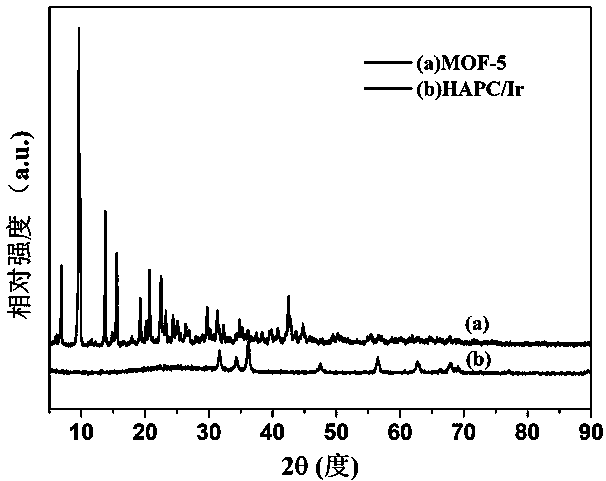

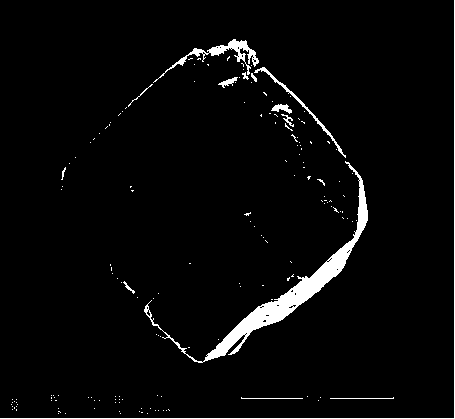

[0028] 3. Heat the precursor solution obtained in 2 in a 100ml autoclave at 100°C for 5 hours to obtain white MOF-5 crystals. See attached figure 1 , figure 1 a is the XRD pattern of MOF-5, the abscissa is the diffraction angle 2θ, the unit is degree (°), and the ordinate is the diffraction intensity. Typical MOF-5 characteristic peaks can be seen in the figure; see the attached figure 2 , figure 2 This is the scanning electron microscope ...

Embodiment 2

[0038] 1. Take 10g of 5A dewatering molecular sieves and sinter at 400°C for 12 hours, then add 500mL of N-methylpyrrolidone (NMP) solvent to dewater for 24 hours before use.

[0039] 2. Take 0.8939g zinc nitrate hexahydrate [Zn(NO 3 ) 2 ·6H 2 O] and 1.8913g trimesic acid (H 3 BDC) was dissolved in 80mL of NMP solvent, then added 0.0111g polyvinylpyrrolidone (PVP), stirred vigorously to dissolve, and slowly added 6µL hydrogen peroxide (H 2 o 2 , 30%), stirred slowly and fully dissolved to obtain the precursor solution.

[0040] 3. Heat the precursor solution obtained in 2 in a 100ml autoclave at 140°C for 5 hours to obtain white MOF-5 crystals.

[0041] 4. Get 2g of MOF-5 prepared in 3 and iridium chloride (IrCl 3 ) 2g was added into 100ml of NMP solvent and soaked for 48 hours, washed with corresponding solvent after centrifugation, repeated 3 times, and vacuum dried at 150°C for 2 hours to obtain HAPC / Ir precursor.

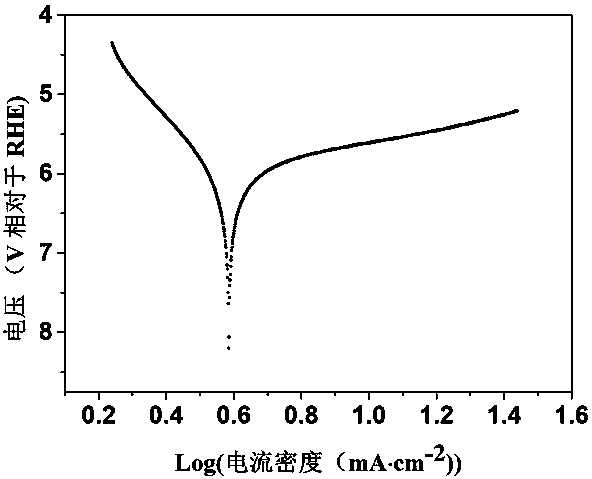

[0042] 5. The dried HAPC / Ir precursor in 4 was sint...

Embodiment 3

[0050] 1. Take 10g of 5A dewatering molecular sieves and sinter at 400°C for 12 hours, then add 500mL of N,N-diethylacetamide (DEF) solution to dewater for 24 hours before use.

[0051] 2. Take 0.8939g zinc nitrate hexahydrate [Zn(NO 3 ) 2 ·6H 2 O] and 1.8913g trimesic acid (H 3 BDC) was dissolved in 180mL of DEF, then 0.0111g of polyvinylpyrrolidone (PVP) was added, stirred vigorously to dissolve, and 120µL of hydrogen peroxide (H 2 o 2 , 30%) and stirred slowly to obtain the precursor solution.

[0052] 3. Heat the precursor solution obtained in 2 in a 200ml autoclave at 140°C for 24 hours to obtain white MOF-5 crystals. MOF-5 was tested by X-ray diffraction (XRD), the abscissa is the diffraction angle 2θ, the unit is degree (°), and the ordinate is the diffraction intensity; typical MOF-5 characteristic peaks can be seen in the XRD diagram; MOF-5 In the scanning electron microscope image, smooth cubic particles can be seen, the particle size is about 8 μm, and the pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com