Cold cathode fluorescent lamp electrode inner coating method

A technology for cold cathode fluorescent lamps and electrodes, which is applied in cold cathode manufacturing, electrode system manufacturing, circuits, etc., can solve problems such as the influence of dark potion concentration, insufficient coating of electrode cups, and influence of lamp tube sealing quality, etc. The effect of potion purity, ensuring low work function, and shortening activation processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

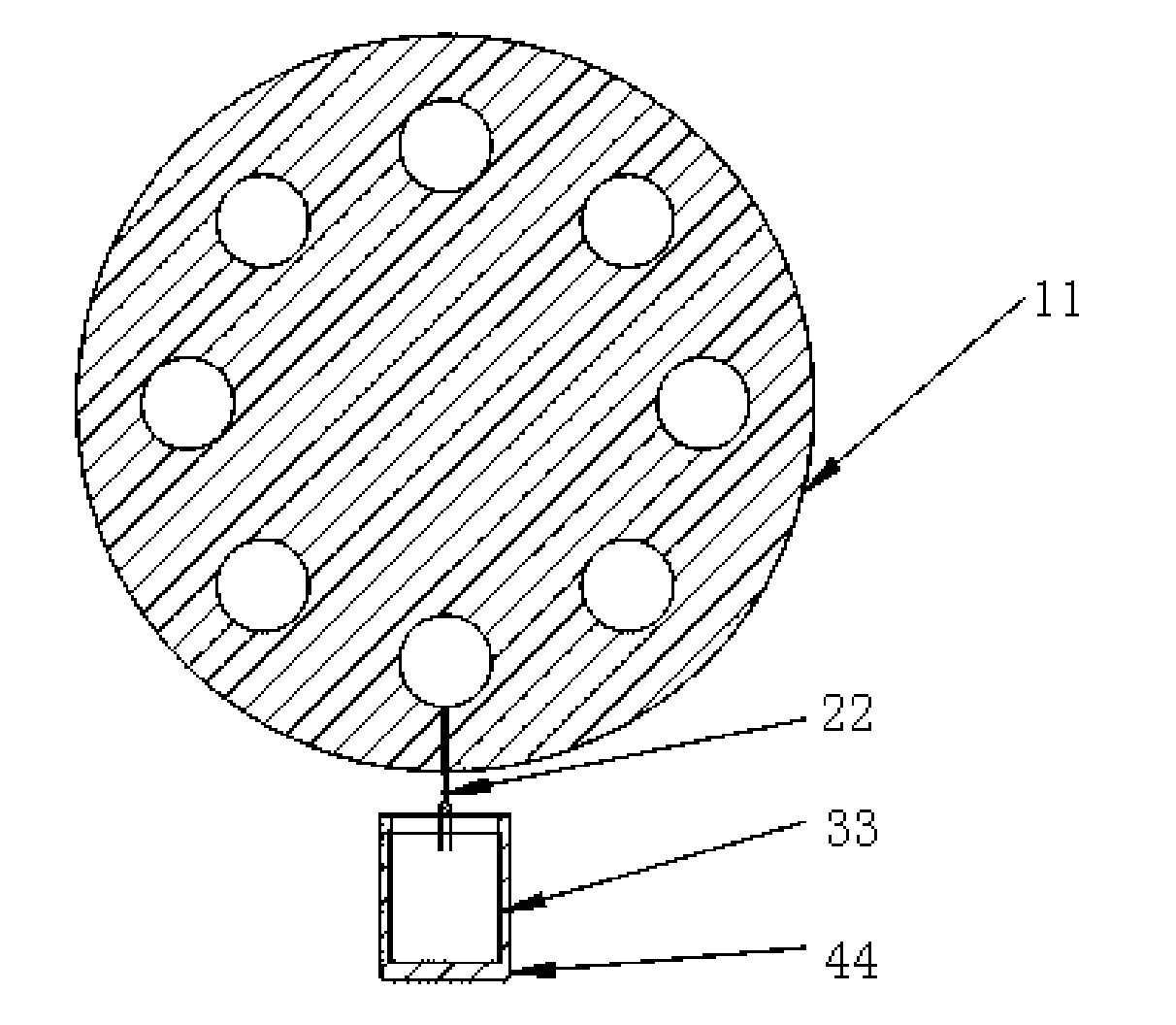

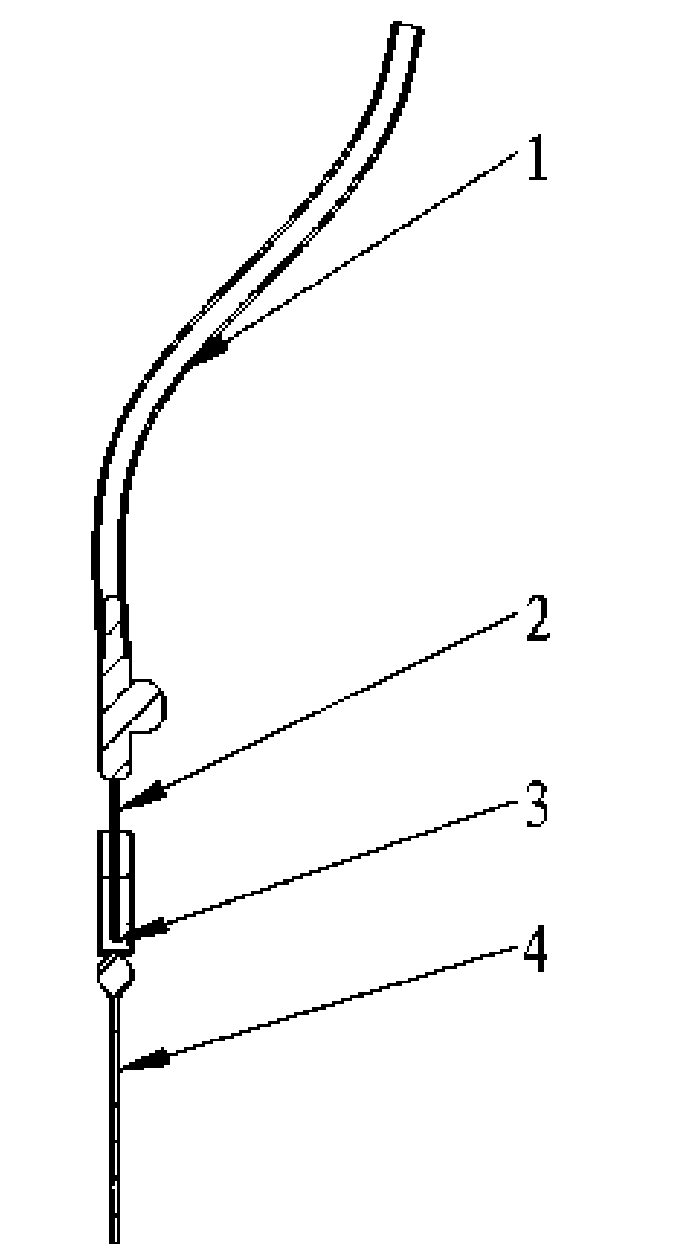

[0017] Such as figure 2 As shown, a cesium sulfate solution with a mass percentage concentration of 2.0%-6.5% is used as the dark potion, blowing air into the dropper 1 with a wind pressure of 0.2MPa, and the high-pressure blowing through the dark potion 3 passes through the dropper 1 and the needle 2 into the In the cold cathode fluorescent lamp electrode cup 4, control the liquid level of the dark potion in the electrode cup 4 to be 2 / 3~4 / 5 of the height of the electrode cup 4, and when the dark potion 3 reaches the set liquid level, absorb the excess dark potion 3. The electrode cup 4 is dried and coated at 250° C. to complete the inner coating film of the electrode of the cold cathode fluorescent lamp.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com