A kind of modified sol and its preparation method and application

A modification and sol technology, applied in sol preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problem of low cracking activity, achieve the effect of improving activity and selectivity, improving coke selectivity, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

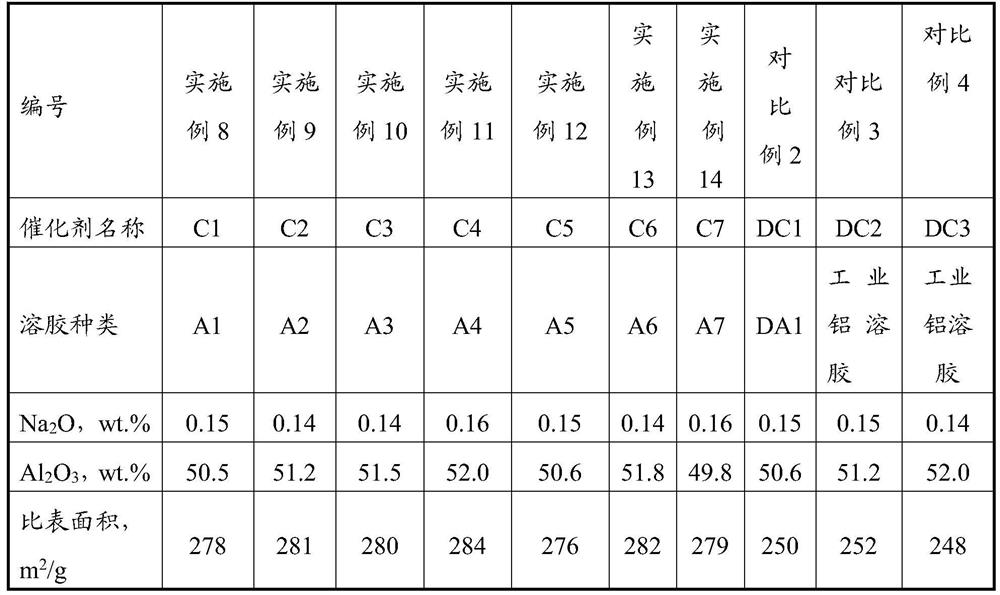

Examples

preparation example Construction

[0040] The present invention also provides the preparation method of above-mentioned modified sol, comprises the following steps:

[0041] mixing the first metal compound, the second metal compound, water and an organic solvent, and then performing first stirring and mixing to obtain a first mixed liquid;

[0042] mixing the first mixed solution with the modified compound and then performing a second stirring and mixing to obtain a second mixed solution;

[0043] After mixing the second mixed solution with hydrogen chloride, the third stirring and mixing is carried out to obtain a modified sol.

[0044] In the present invention, the first metal compound, the second metal compound, water and the organic solvent are mixed and then first stirred and mixed to obtain the first mixed liquid.

[0045] In the present invention, the temperature of the first stirring and mixing is preferably 20-90°C, more preferably 30-60°C, most preferably 40-50°C; the time of the first stirring and m...

Embodiment 1

[0081] Mix 1613g of pseudo-boehmite and 1720g of deionized water for beating and disperse evenly; take 1895g of zirconium oxychloride ZrOCl 2 ·8H 2 0 and 261g ethanol, join in the above-mentioned slurry, stir at room temperature for 3h; then slowly add 984g phosphoric acid solution (98wt.%), continue to stir at room temperature for 1h, then add 397g hydrochloric acid solution (36wt.%), stir for 2h, obtain the improved Sex Sol A1. After analysis, in this modified sol, Al mass content is 7.8%, Zr content mass is 7.6%, Cl mass content is 2.0%, P mass mass is 3.8%, P / Al (mass ratio) 0.5, Al / Cl (mole ratio) 5.0, Zr / Al (molar ratio) 0.3.

Embodiment 2

[0083] Mix 1000g of zinc oxide and 3545g of deionized water for beating, and disperse evenly; take 394g of ferric chloride and 148g of n-hexane, add them to the above slurry, heat up to 40°C, and stir for 2h; then slowly add 392g of ammonium dihydrogen phosphate, 40 After stirring for 3 hours at °C, 496 g of hydrochloric acid solution (36 wt.%) was added, and stirring was continued for 3 hours to obtain modified sol A2. After analysis, Zn mass content is 8.6% in this modified sol, Fe content mass is 2.3%, Cl mass content is 2.8%, P mass mass is 1.7%, P / Al (mass ratio) 0.2, Zn / Cl (mole Ratio) 4.0, Fe / Zn (molar ratio) 0.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com