Vertical structure algan/gan HEMT device and fabrication method thereof

A vertical structure and device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as large leakage, lattice damage, and complexity, and achieve low resistivity, enhanced withstand voltage characteristics, and withstand voltage The effect of property changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

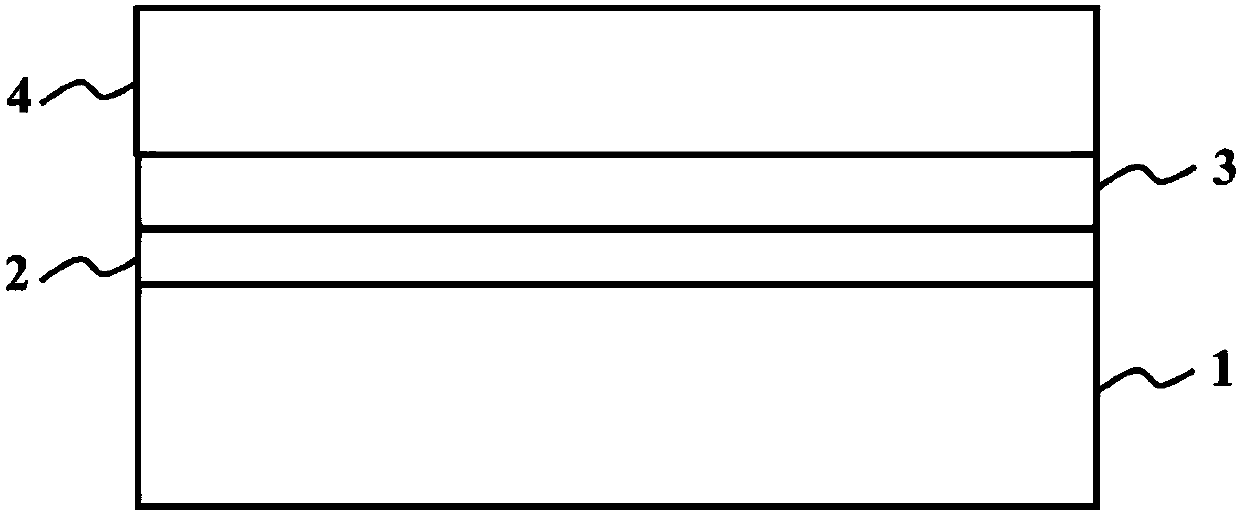

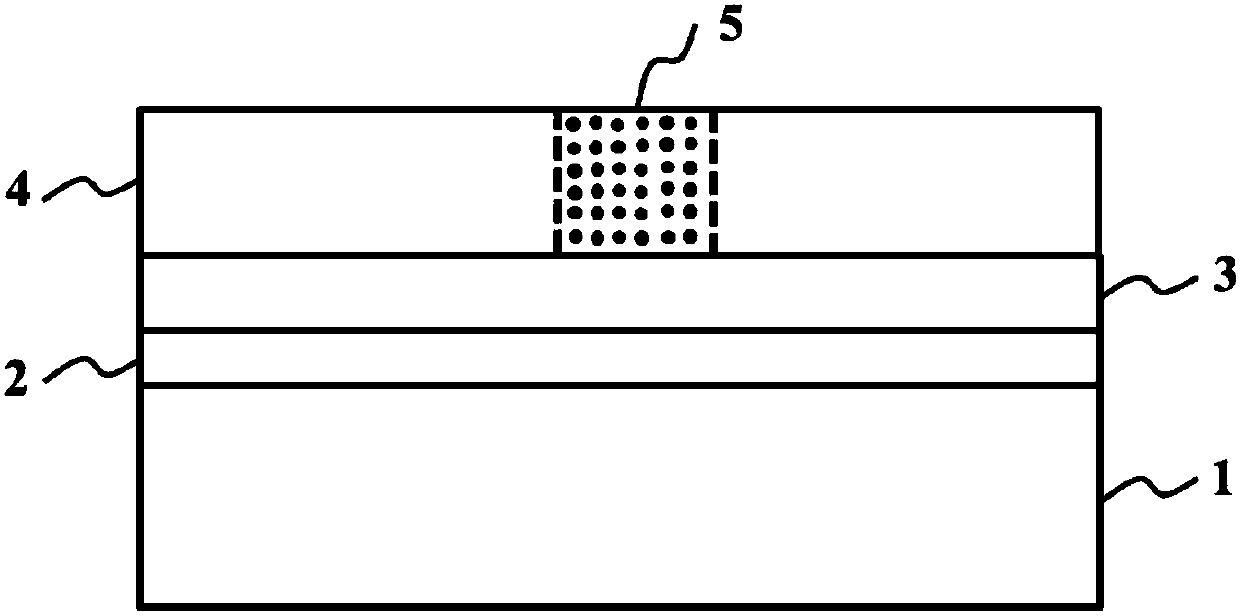

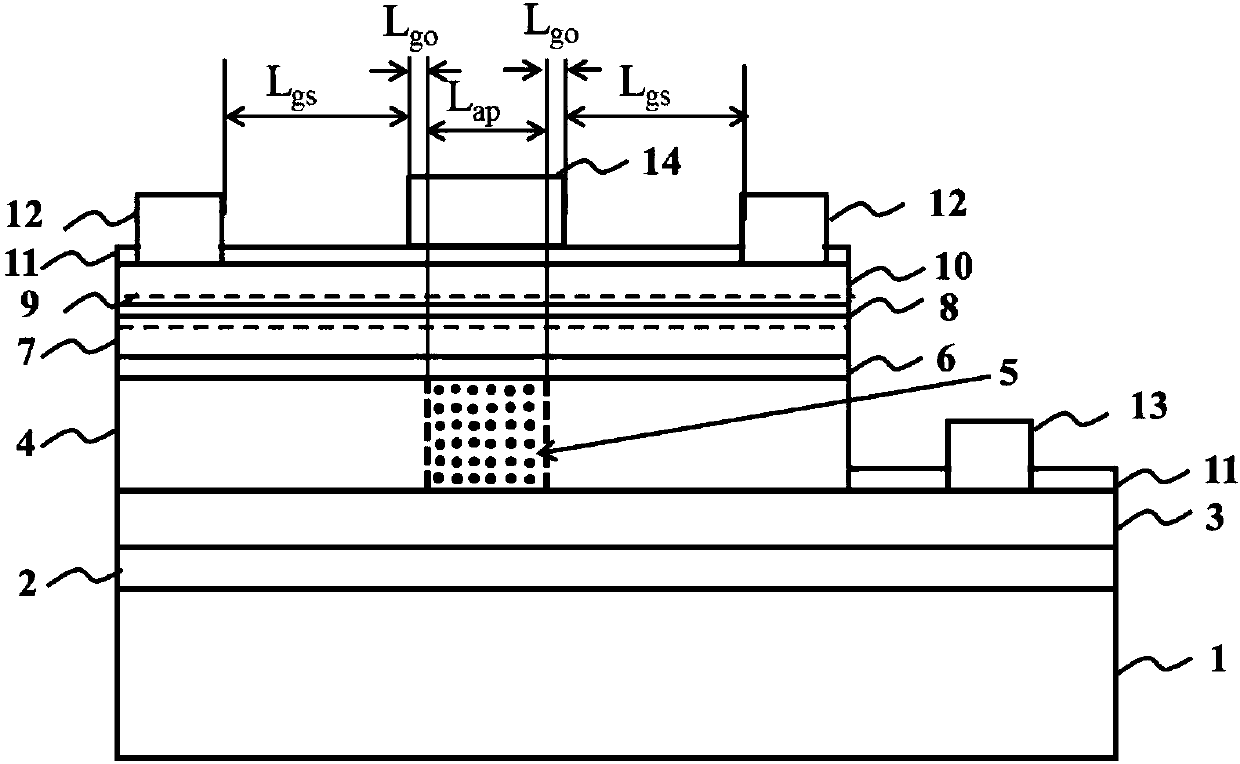

[0031] The embodiment of the present invention discloses a vertical structure AlGaN / GaN HEMT device, including a substrate, and an n+GaN layer, a high-resistance GaN layer, an intrinsic GaN layer, and an AlGaN layer sequentially formed on the substrate, and also includes A drain electrode forming ohmic contact with the n+GaN layer, a source electrode forming ohmic contact with the AlGaN layer, and a gate electrode, the high-resistance GaN layer serving as a current blocking layer including a current formed by Si ion implantation The through hole is conducted, and the current conduction through hole penetrates the high-resistance GaN layer up and down.

[0032]In the above-mentioned vertical structure AlGaN / GaN HEMT device, n+GaN and high-resistance GaN are epitaxially grown for the first time by MOCVD, and the intrinsic GaN layer and the AlGaN layer are formed by secondary epitaxy by MOCVD.

[0033] In this technical scheme, the existing high-resistance GaN is used as the curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com