Preparation method of alcohol resisting type polyarylether electrolyte film material

An electrolyte membrane material, polyarylether technology, applied in fuel cell parts, circuits, electrical components, etc., can solve problems such as poor alcohol resistance, achieve excellent film formation, simple synthesis method, and promote proton conduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

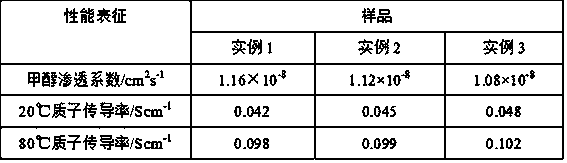

Examples

example 1

[0017] Take the collagen and put it in a pulverizer to pulverize it, collect the pulverized material and mix it with deionized material with stirring at a mass ratio of 1:10, and adjust the pH to 8.0 with a mass fraction of 1% ammonia solution to obtain a modified solution and press 50U / g, add neutral protease to the modified solution, then hydrolyze at 35°C for 3h, filter and collect the filtrate to obtain hydrolyzed collagen solution; weigh 45 parts of hydrolyzed collagen solution, 10 parts of polyvinyl alcohol, 3 parts of glutaraldehyde, 1 part of 1% hydrochloric acid and 55 parts of 120# solvent oil were placed in a three-necked flask, heated in a water bath at 75°C for 3 hours, allowed to stand and cooled to room temperature, filtered and collected the filtrate , after washing 3 times with acetone, the modified cross-linked particles were obtained; in parts by weight, 45 parts of dimethyl sulfoxide, 10 parts of epichlorohydrin, 3 parts of 1% sodium hydroxide solution and 1...

example 2

[0019]Take the collagen and put it in a pulverizer to pulverize it, collect the pulverized material and mix it with deionized material with stirring at a mass ratio of 1:10, and adjust the pH to 8.0 with a mass fraction of 1% ammonia solution to obtain a modified solution and press 50U / g, add neutral protease to the modified liquid, then hydrolyze at 36°C for 4h, filter and collect the filtrate to obtain hydrolyzed collagen liquid; weigh 47 parts of hydrolyzed collagen liquid, 12 parts of polyvinyl alcohol, 4 parts of glutaraldehyde, 2 parts of 1% hydrochloric acid and 57 parts of 120# solvent oil were placed in a three-necked flask, heated in a water bath at 77°C for 4 hours, left to cool to room temperature, filtered and collected the filtrate , after washing with acetone for 4 times, the modified cross-linked particles were obtained; in parts by weight, 47 parts of dimethyl sulfoxide, 12 parts of epichlorohydrin, 4 parts of 1% sodium hydroxide solution and 12 parts of mass f...

example 3

[0021] Take the collagen and put it in a pulverizer to pulverize it, collect the pulverized material and mix it with deionized material with stirring at a mass ratio of 1:10, and adjust the pH to 8.0 with a mass fraction of 1% ammonia solution to obtain a modified solution and press 50U / g, add neutral protease to the modified solution, then hydrolyze at 37°C for 5h, filter and collect the filtrate to obtain hydrolyzed collagen solution; weigh 50 parts of hydrolyzed collagen solution, 15 parts of polyvinyl alcohol, 5 parts of glutaraldehyde, 2 parts of 1% hydrochloric acid and 65 parts of 120# solvent oil were placed in a three-necked flask, heated in a water bath at 80°C for 5 hours, left to cool to room temperature, filtered and collected the filtrate , after washing 5 times with acetone, the modified cross-linked particles were obtained; in parts by weight, 50 parts of dimethyl sulfoxide, 15 parts of epichlorohydrin, 5 parts of 1% sodium hydroxide solution and 15 parts of mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com