Liquid metal composite proton exchange membrane for methanol fuel battery as well as preparation method thereof

A methanol fuel cell, proton exchange membrane technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of difficult reduction of oxidants, size change, methanol occupation, etc., and achieve high proton conductivity, difficult to size change, and good size. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

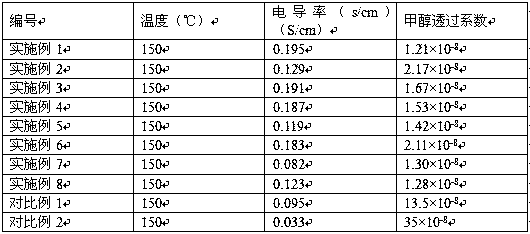

Examples

Embodiment 1

[0039] Example 1 Preparation of Liquid Metal Composite Proton Exchange Membrane for Methanol Fuel Cell

[0040] Prepared as follows:

[0041] a. Weighing the reaction raw materials: 12 parts by weight of bismuth-tin alloy, 25 parts by weight of sulfonated polyether ether ketone, and 10 parts by weight of sodium phosphotungstate.

[0042] b. Take the sulfonated polyether ether ketone in the above parts by weight and use the low-temperature cryogenic airflow crushing system to crush the material, and conduct heat exchange with the material through the liquid nitrogen cold source to cool the material to -140°C. The low-temperature material is subjected to low temperature in the crushing area. High-pressure nitrogen impact crushing, the crushed material is classified by eddy current, the particle size of the fine powder after classification can reach 2.0-8.0 microns, and it is crushed into fine powder sulfonated polyether ether ketone;

[0043] c. Take bismuth-tin alloy and sodiu...

Embodiment 2

[0044] Example 2 Preparation of Liquid Metal Composite Proton Exchange Membrane for Methanol Fuel Cell

[0045] Prepared as follows:

[0046] a. Weighing the reaction raw materials: 10 parts by weight of bismuth-tin alloy, 22 parts by weight of sulfonated polyether ether ketone, and 7 parts by weight of sodium phosphotungstate.

[0047] b. Take the sulfonated polyether ether ketone in the above parts by weight and use the low-temperature cryogenic airflow crushing system to crush the material, and conduct heat exchange with the material through the liquid nitrogen cold source to cool the material to -140°C. The low-temperature material is subjected to low temperature in the crushing area. High-pressure nitrogen impact crushing, the crushed material is classified by eddy current, the particle size of the fine powder after classification can reach 2.0-8.0 microns, and it is crushed into fine powder sulfonated polyether ether ketone;

[0048] c. Take bismuth-tin alloy and sodium...

Embodiment 3

[0049] Example 3 Preparation of Liquid Metal Composite Proton Exchange Membrane for Methanol Fuel Cell

[0050] Prepared as follows:

[0051] a. Weighing the reaction raw materials: 16 parts by weight of bismuth-tin alloy, 26 parts by weight of sulfonated polyether ether ketone, and 12 parts by weight of sodium phosphotungstate.

[0052] b. Take the sulfonated polyether ether ketone in the above parts by weight and use the low-temperature cryogenic airflow crushing system to crush the material, and conduct heat exchange with the material through the liquid nitrogen cold source to cool the material to -140°C. The low-temperature material is subjected to low temperature in the crushing area. High-pressure nitrogen impact crushing, the crushed material is classified by eddy current, the particle size of the fine powder after classification can reach 2.0-8.0 microns, and it is crushed into fine powder sulfonated polyether ether ketone;

[0053] c. Take bismuth-tin alloy and sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com