Preparation of novel covalent cross-linking polybenzimidazole proton exchange membrane

A technology of benzimidazole membrane and proton exchange membrane, which is applied in the field of preparation of new cross-linked polybenzimidazole membrane, can solve the problems that restrict the wide commercialization of PBI membrane, low mechanical strength and high swelling, and achieve simple and feasible preparation process, High mechanical strength, effect of improving anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

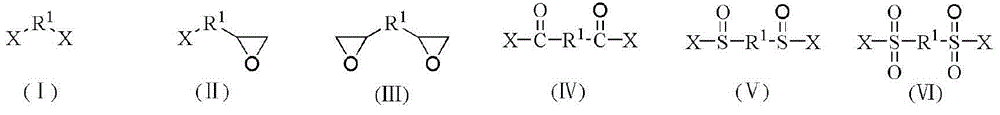

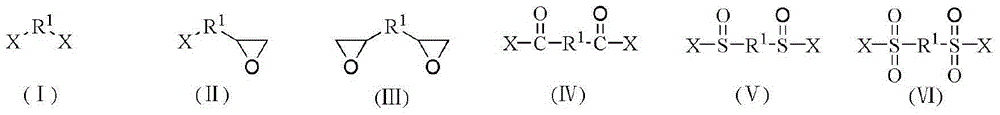

Method used

Image

Examples

Embodiment 1

[0022] Add a certain amount of polybenzimidazole resin into the N,N-dimethylacetamide solution and dissolve it with slight heat to obtain a polymer with a mass fraction of 0.1wt.%-50wt.% (preferably 0.1wt.%-10wt.%) solution, and then add 1,2-dibromoethane with a mass fraction of 0.1wt.%-50wt.% (preferably 0.1wt.%-10wt.%), and magnetically stir to make it evenly mixed; vacuum filtration, A uniform proton exchange membrane solution containing a cross-linking agent is obtained; the cast film forming method is used, the temperature is raised, and the solvent is volatilized to remove the solvent to obtain the desired cross-linked proton exchange membrane.

Embodiment 2

[0024] Add a certain amount of polybenzimidazole resin into the N,N-dimethylacetamide solution and dissolve it with slight heat to obtain a polymer with a mass fraction of 0.1wt.%-50wt.% (preferably 0.1wt.%-10wt.%) solution, and then add epichlorohydrin with a mass fraction of 0.1wt.%-50wt.% (preferably 0.1wt.%-10wt.%), and magnetically stir to make it evenly mixed; The proton exchange membrane solution of the linking agent; the casting film forming method is adopted, the temperature is raised, and the solvent is volatilized to remove the solvent to obtain the required cross-linked proton exchange membrane.

Embodiment 3

[0026] Add a certain amount of polybenzimidazole resin into the N,N-dimethylacetamide solution and dissolve it with slight heat to obtain a polymer with a mass fraction of 0.1wt.%-50wt.% (preferably 0.1wt.%-10wt.%) solution, and then add 1,2,5,6-dioxirane with a mass fraction of 0.1wt.%-50wt.% (preferably 0.1wt.%-10wt.%), and magnetically stir to make it evenly mixed; Suction filtration under reduced pressure to obtain a uniform proton exchange membrane solution containing a cross-linking agent; adopt a tape-casting film-forming method, program temperature rise, and evaporate the solvent to obtain the desired cross-linked proton exchange membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com