Fully synthetic aluminum alloy grinding fluid and preparation method thereof

An aluminum alloy, fully synthetic technology, used in lubricating compositions, petroleum industry, etc., can solve the problems of insufficient lubricity, poor cleaning, reducing heat, etc., achieve good wettability, improve cleaning effect, and good lubricity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

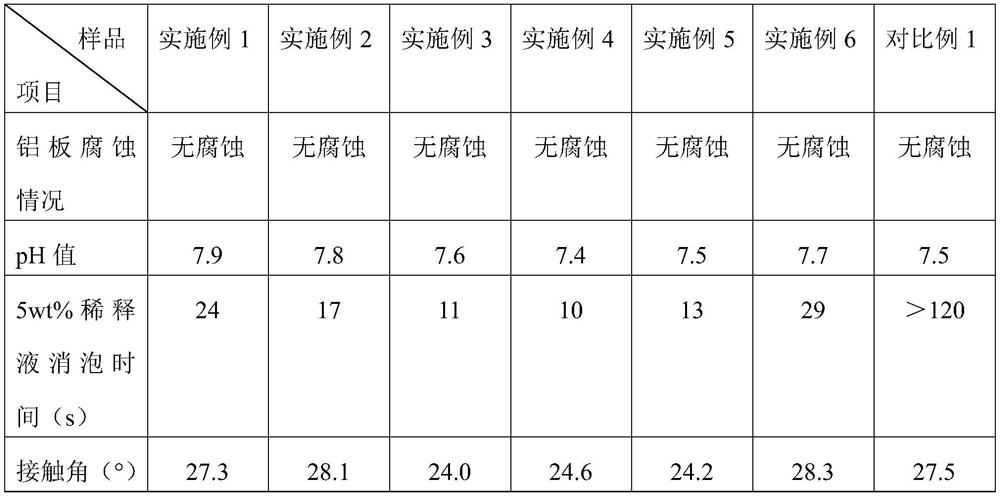

Examples

Embodiment 1

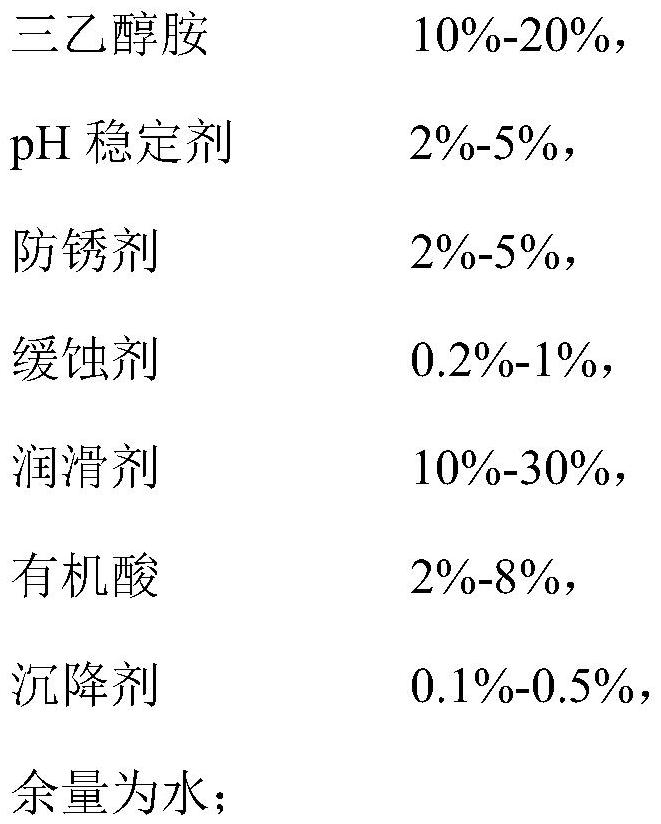

[0024] The fully synthetic aluminum alloy grinding fluid provided by this embodiment comprises the following components by weight percentage: 20% of triethanolamine, 5% of monoisopropanolamine, 2% of dodecanedioic acid, and benzotriazole 0.5%, 3-amino-1,2,4-triazole 0.5%, polyethylene glycol polypropylene glycol monobutyl ether (cloud point: 55°C) 30%, neodecanoic acid 4%, isononanoic acid 4% , 0.1% polyoxyethylene dimethylimmonium chloride, and the balance is water.

[0025] The preparation method of the above-mentioned fully synthetic aluminum alloy grinding fluid comprises the following steps: first adding triethanolamine, water, dodecanedioic acid, benzotriazole, 3-amino-1,2, 4-Triazole, stir until the solid dissolves, then add monoisopropanolamine, polyethylene glycol polypropylene glycol monobutyl ether, neodecanoic acid, isononanoic acid, polyoxyethylene dimethylimmonium chloride, and stir Evenly, that is.

Embodiment 2

[0027] The fully synthetic aluminum alloy grinding fluid provided in this embodiment comprises the following components by weight percentage: 10% triethanolamine, 2% diglycolamine, 2% sebacic acid, 3% triazine triaminocaproic acid, Tolylbenzotriazole 0.1%, 3-amino-5-mercapto-1,2,4-triazole 0.1%, polyethylene glycol polypropylene glycol monobutyl ether (cloud point: 65°C) 10%, new 2% capric acid, 0.5% polyoxyethylene dimethylimmonium chloride, and the balance is water.

[0028] The preparation method of the above-mentioned fully synthetic aluminum alloy grinding fluid comprises the following steps: first adding triethanolamine, water, sebacic acid, triazine triaminocaproic acid, methylbenzotriazole, 3- Amino-5 mercapto-1,2,4-triazole, stirred until the solid is dissolved, then add diglycolamine, polyethylene glycol polypropylene glycol monobutyl ether, neodecanoic acid, polyoxyethylene dimethyl chloride Ammonium, stir well, that is.

Embodiment 3

[0030] The fully synthetic aluminum alloy grinding fluid provided in this example comprises the following components by weight percentage: 20% triethanolamine, 3% 2-amino-2-methyl 1-propanol, 3% sebacic acid, mercapto Thiadiazole 0.4%, polyethylene glycol polypropylene glycol monobutyl ether (cloud point: 55° C.) 25%, isononanoic acid 4%, polyoxyethylene dimethylimmonium chloride 0.4%, and the balance is water.

[0031] The preparation method of the above-mentioned fully synthetic aluminum alloy grinding fluid comprises the following steps: firstly add triethanolamine, water, sebacic acid, and mercaptothiadiazole to the reaction kettle in sequence, stir until the solid dissolves, and then add 2-amino- 2-Methyl 1-propanol, polyethylene glycol polypropylene glycol monobutyl ether, isononanoic acid, polyoxyethylene dimethylimmonium chloride, and stir evenly to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com