Lithium titanate composite material, preparation method and applications thereof

A composite material and lithium titanate technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, electrical components, etc., can solve the problem that it is impossible to ensure that a uniform and continuous zirconium phosphate protective layer is formed on the surface of the particles, and the thickness of the coating layer is uncontrollable , the coating layer is not uniform enough, etc., to achieve the effects of suppressing side reactions, being environmentally friendly, and avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

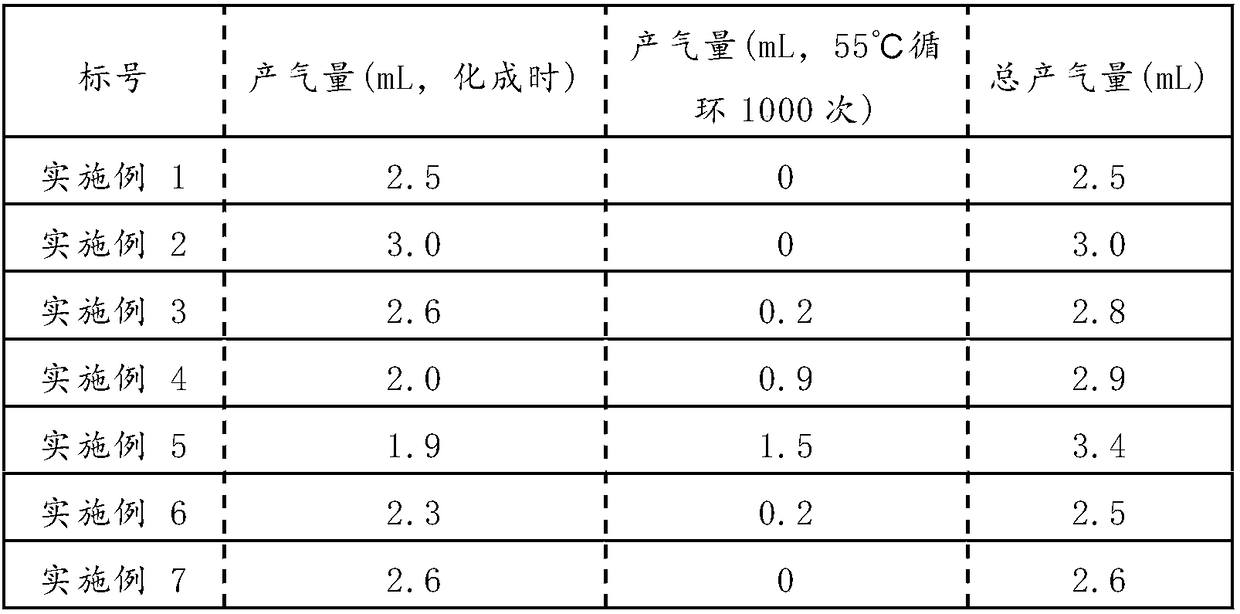

Embodiment 1

[0028] Add the lithium titanate bulk material into a three-neck round bottom flask, add absolute ethanol, deionized water (70 ml) and ammonia water (4 ml) respectively, and disperse ultrasonically for 5 minutes. Then, 3 ml of ethyl orthosilicate was added, stirred at room temperature for 10 hours, filtered, and washed with deionized water and ethanol three times respectively, to obtain a composite material with a core-shell structure. By adjusting the particle size of lithium titanate bulk, the amount of tetraethyl orthosilicate and ammonia water, SiO with adjustable coating thickness can be obtained. 2 Coated lithium titanate composite material.

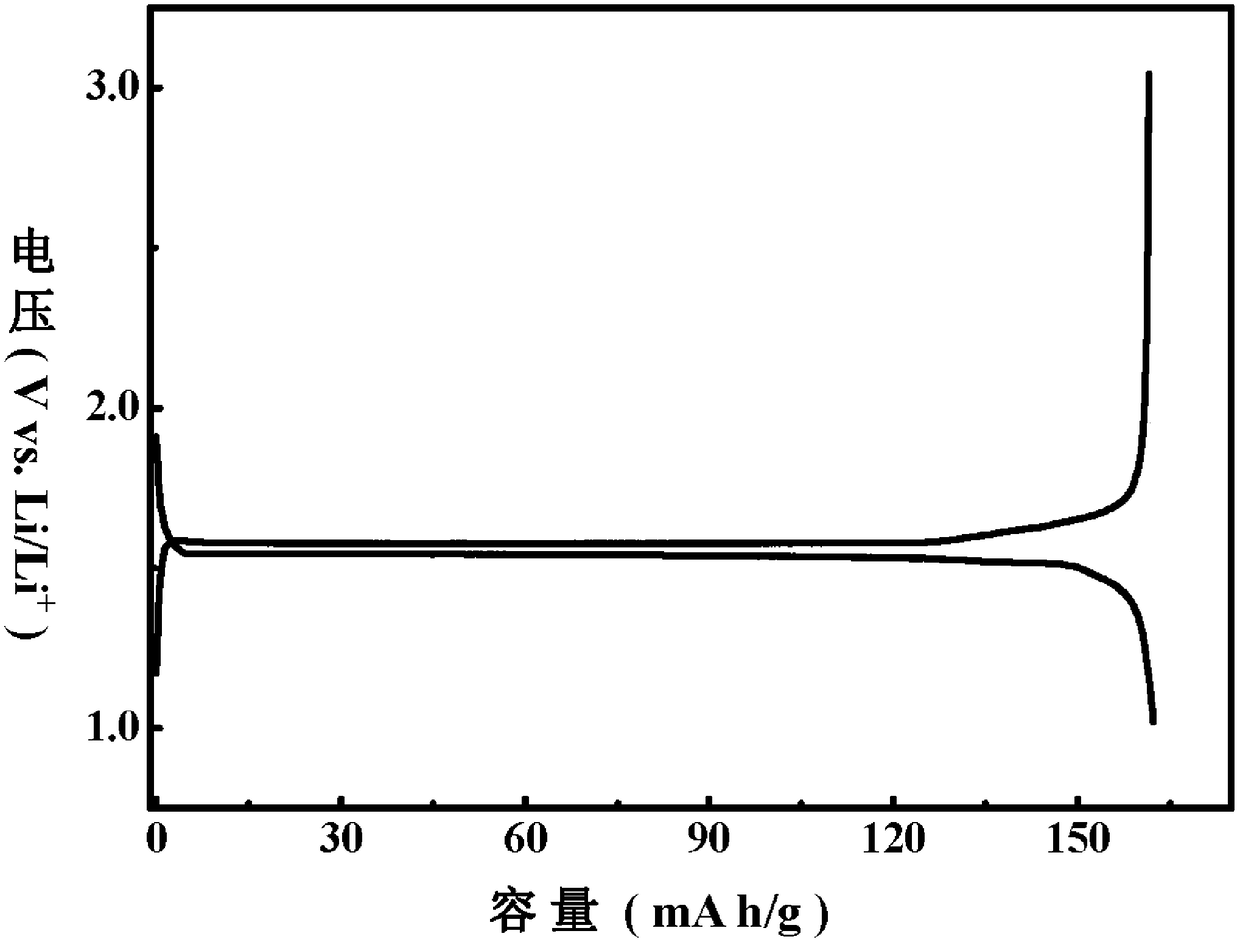

[0029] The TEM photos of lithium titanate materials before and after coating are as follows: figure 1 shown in a and 1b. The results show that the lithium titanate composite material obtained by the above method has a uniform and continuous surface coating layer, and the thickness of the coating layer is about 15 nm.

Embodiment 2

[0031] Add the lithium titanate bulk material into a three-neck round bottom flask, add absolute ethanol, deionized water (70 ml) and ammonia water (4 ml) respectively, and disperse ultrasonically for 5 minutes. Then, add 6 milliliters of tetraethyl orthosilicate, stir at room temperature for 10 hours, filter, wash with deionized water and ethanol three times respectively, and obtain amorphous SiO with core-shell structure. 2 Composite wrap.

Embodiment 3

[0033] Add the lithium titanate bulk material into a three-neck round bottom flask, add absolute ethanol, deionized water (70 ml) and ammonia water (4 ml) respectively, and disperse ultrasonically for 5 minutes. Then, add 3 milliliters of tetraethyl orthosilicate, stir at room temperature for 5 hours, filter, wash with deionized water and ethanol three times respectively, and obtain amorphous SiO with core-shell structure. 2 Composite wrap.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com