A kind of silicon carbide ceramic and preparation method thereof

A silicon carbide ceramic and silicon carbide technology, applied in the field of ceramic materials, can solve problems such as the destruction of silicon dioxide protective film and the reduction of anti-oxidation performance, and achieve the effects of improving anti-oxidation performance, small quality change, and reducing oxygen diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

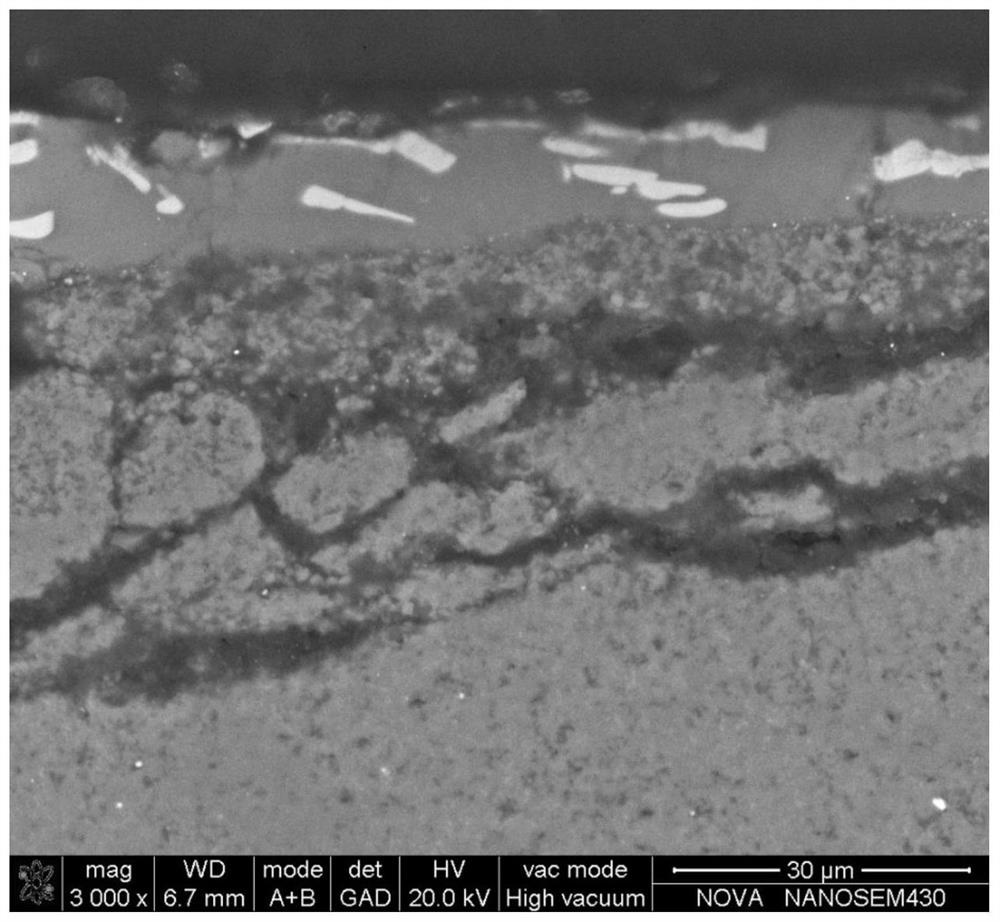

Image

Examples

preparation example Construction

[0032] The invention provides a preparation method of silicon carbide ceramics, which solves the technical problem in the prior art that the silicon carbide protective film of silicon carbide ceramics is damaged during liquid phase sintering, resulting in the reduction of its anti-oxidation performance. The silicon carbide ceramic prepared by the method has high compactness and good oxidation resistance, and can be widely used in the fields of machinery, chemical industry, microelectronics, automobile, petroleum and processing.

[0033] The silicon carbide ceramic provided by the present invention and the preparation method thereof will be further described below.

Embodiment 1

[0035] (1) Silicon carbide (SiC) powder with a mass ratio of 90:6:4, alumina (Al) 2 O 3 ) powder and yttrium trioxide (Y 2 O 3 ) powder is mixed as the basic raw material to obtain SiC-Al 2 O 3 -Y 2 O 3 Mix powder. SiC-Al 2 O 3 -Y 2 O 3 Mixed powder with tantalum diboride (TaB) in a volume ratio of 85:15 2 ) powder is mixed and dissolved in ethanol to form silicon nitride (Si 3 N 4 ) ball is the ball milling medium, and the ball is milled on a planetary ball mill at a speed of 300 r / min for 8 hours. After wet mixing and drying, uniform SiC-Al is obtained. 2 O 3 -Y 2 O 3 -TaB 2 Mix powder.

[0036] (2) SiC-Al 2 O 3 -Y 2 O 3 -TaB 2 The mixed powder is sieved and granulated to obtain SiC-Al 2 O 3 -Y 2 O 3 -TaB 2 Granulated balls.

[0037] (3) SiC-Al 2 O 3 -Y 2 O 3 -TaB 2 The granulated balls were poured into a hot-pressed graphite mold, and in an argon atmosphere of 1 atm, the pressure was started when the temperature reached 1400 °C at a heating...

Embodiment 2

[0039] (1) SiC powder with a mass ratio of 90:6:4, Al 2 O 3 Powder and Y 2 O 3 Powder is mixed as basic raw material to obtain SiC-Al 2 O 3 -Y 2 O 3 Mix powder. SiC-Al 2 O 3 -Y 2 O 3 Mixed powder with TaB2 The powders were mixed in a volume ratio of 90:10 and dissolved in ethanol to form silicon nitride (Si 3 N 4 ) ball is the ball milling medium, and the ball is milled on a planetary ball mill at a speed of 300 r / min for 8 hours. After wet mixing and drying, uniform SiC-Al is obtained. 2 O 3 -Y 2 O 3 -TaB 2 Mix powder.

[0040] (2) SiC-Al 2 O 3 -Y 2 O 3 -TaB 2 The mixed powder is sieved and granulated to obtain SiC-Al 2 O 3 -Y 2 O 3 -TaB 2 Granulated balls.

[0041] (3) SiC-Al 2 O 3 -Y 2 O 3 -TaB 2 The granulated balls were poured into a hot-pressed graphite mold, and in an argon atmosphere of 1 atm, the pressure was started when the temperature reached 1400 °C at a heating rate of 10 °C / min, and the temperature reached 1800 °C while the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com