Ultralow dielectric constant microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and ultra-low dielectric constant technology, applied in the field of ceramic materials and their preparation, can solve the problems of high resonant frequency temperature coefficient, poor sintering characteristics, etc. The effect of a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

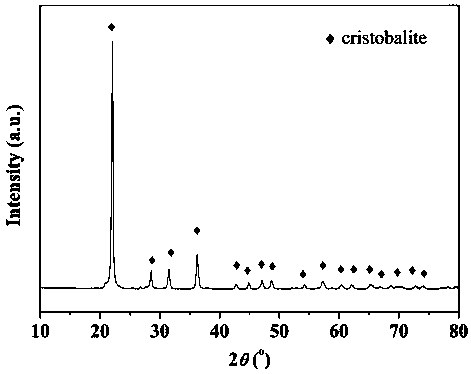

Image

Examples

Embodiment 1

[0020] Weigh the sintering aid analytically pure CaF 2 0.5g, analytically pure MnO 2 2.5g, put it in an agate mortar and grind it by hand for 20min, and then use it for later use. Weigh out 95g of fused silica powder with a purity greater than 99%, a crystallinity of 0-5%, a particle size of 1-1.5μm and a purity greater than 99.9%, and a particle size of 500nm Put 2g of quartz powder in a rolling mill tank for 9 hours, take out the mixed powder and put it in a ball mill tank, mix it with ethanol for 1 hour and take it out, add manually ground CaF to the slurry 2 +MnO 2 Continue ball milling for 5 hours after the auxiliary agent is powdered, add 0.6wt% methylcellulose to the dried powder and mix, then slowly add 0.9wt% methylcellulose dropwise during the granulation process for granulation , the granulated material is sieved to obtain a coarse powder between 150 mesh and 400 mesh, and then put it into a metal mold for cold pressing to form, and place the formed block in a hig...

Embodiment 2

[0022] Weigh the sintering aid analytically pure CaF 2 1g, analytically pure MnO 2 2g, put it in an agate mortar and grind it by hand for 25min, then take it for later use, weigh 94.5g of fused silicon micropowder with a purity greater than 99%, a crystallinity of 0-5%, a particle size of 1-1.5μm and a purity greater than 99.9%, and a particle size of 500nm Put 2.5g of quartz powder in a tumbling tank and grind it for 10 hours. The mixed powder is taken out and placed in a ball milling tank, mixed with ethanol for 1 hour, taken out, and manually ground CaF 2 +MnO 2 Continue ball milling for 6 hours after the auxiliary agent is powdered, first add 1.5wt% methylcellulose to the dried powder and mix, then slowly add 1.5wt% methylcellulose dropwise during the granulation process for granulation , the granulated material is sieved to obtain a coarse powder between 150 mesh and 400 mesh, and then put it into a metal mold for cold pressing to form, and place the formed block in a h...

Embodiment 3

[0024] Weigh the sintering aid analytically pure CaF 2 1.5g, analytically pure MnO 2 1.5g, put it in an agate mortar and grind it by hand for 30min, and then use it for later use. Weigh 94g of fused silicon micropowder with a purity greater than 99%, a crystallinity of 0-5%, a particle size of 1-1.5μm and a purity greater than 99.9%, and a particle size of 500nm Put 3g of quartz powder in a tumbling tank and grind for 11 hours. The mixed powder is taken out and placed in a ball milling tank, mixed with ethanol for 1.5 hours and taken out. Add manually ground CaF to the slurry. 2 +MnO 2 After the auxiliary powder is powdered, continue ball milling for 7 hours, add stearic acid accounting for 0.6wt% of the powder to the dried powder and mix, and then slowly add stearic acid accounting for 0.9wt% of the powder dropwise during the granulation process for granulation. The pellets are sieved to obtain a coarse powder between 150 mesh and 400 mesh, and then put into a metal mold fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com