A zirconia-based ceramic back plate and its preparation method and application

A ceramic backplane, zirconia-based technology, applied in branch office equipment, telephone structure, electrical components, etc., can solve the problems of low mechanical strength, high organic content, low ceramic compactness, etc., and achieve strong wear resistance, Simple preparation method and high sintering compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0080] According to a second embodiment of the present invention, a method for preparing a zirconia-based ceramic backplane or a method for preparing a zirconia-based ceramic backplane according to the first embodiment is provided.

[0081] A method for preparing a zirconia ceramic back plate, the method comprising the steps of:

[0082] 1) Weigh each raw material in proportion and stir to mix evenly. Then it is placed in an isostatic pressing mold cover to obtain an isostatic pressing green body.

[0083] 2) The isostatic pressed green body obtained in step 1) is placed in a sintering machine for pre-sintering treatment, and the pre-sintered green body is obtained after cooling.

[0084] 3) Slicing the calcined body obtained in step 2) to obtain thin slices.

[0085] 4) Sintering the flakes obtained in step 3) again, and finally obtaining a zirconia ceramic back plate after surface treatment.

[0086] As preferably, the proportioning of each component raw material addition...

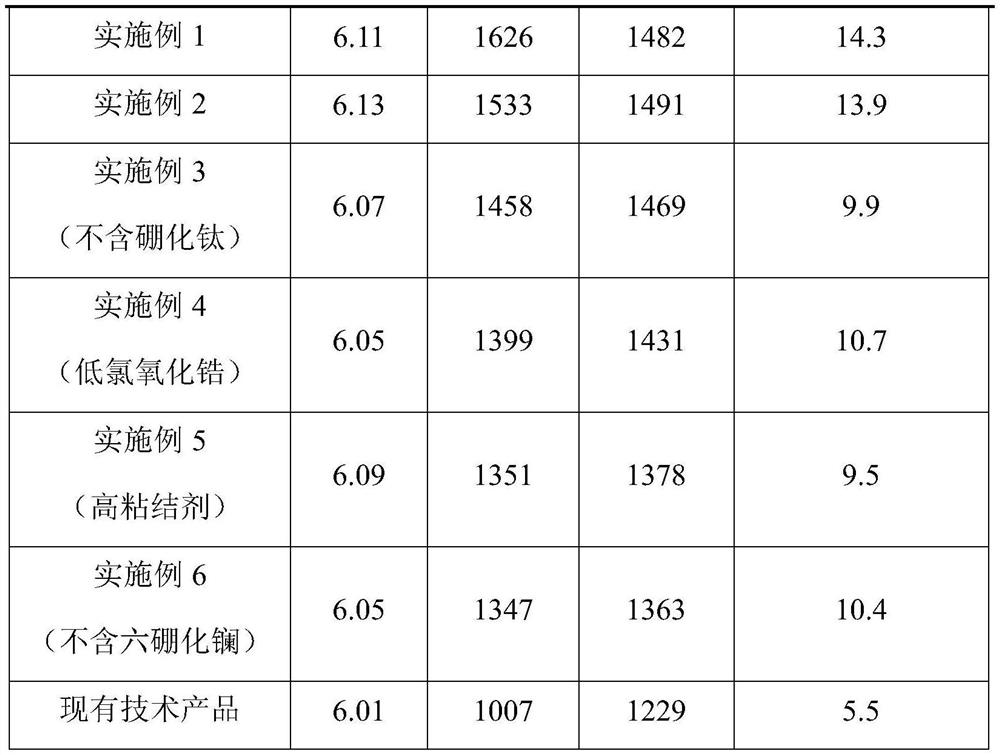

Embodiment 1

[0106] 7.5kg of zirconia stabilized with magnesia-yttria composite stabilizer (8wt% magnesia+2wt% yttrium oxide+90% zirconia, the average particle size of zirconia is 15nm), 0.6kg lanthanum hexaboride (average particle size diameter of 15 μm), 0.1 kg of binder and 0.85 kg of titanium boride (average particle size of 10 μm) were put into the container, and then a saturated aqueous solution containing 1.8 kg of zirconium oxychloride (average particle size of 15 μm) and 4 kg of hydrogen peroxide were added And after stirring at room temperature for 24h, the mixture was obtained. The mixture was then dried at 110 °C for 1.5 h and ground to nanoscale. After the drying and grinding are completed, the isostatic pressing green body is obtained after pressing in the isostatic pressing mold sleeve under a pressure of 500 MPa and keeping the pressure for 15 minutes. Next, the isostatic pressed green body is heated to 1050° C. in a sintering machine at a rate of 15° C. / h for sintering an...

Embodiment 2

[0108] 6.5kg of zirconia stabilized with magnesia-yttria composite stabilizer (8wt% magnesia+2wt% yttrium oxide+90% zirconia, the average particle size of zirconia is 15nm), 0.8kg lanthanum hexaboride (average particle size diameter of 15 μm), 0.08 kg of binder and 0.8 kg of titanium boride (average particle size of 10 μm) were put into the container, and then a saturated aqueous solution containing 2.62 kg of zirconium oxychloride (average particle size of 15 μm) and 5 kg of hydrogen peroxide were added And after stirring at room temperature for 24h, the mixture was obtained. The mixture was then dried at 110 °C for 1.5 h and ground to nanoscale. After the drying and grinding are completed, the isostatic pressing green body is obtained after pressing in the isostatic pressing mold sleeve under a pressure of 500 MPa and keeping the pressure for 15 minutes. Next, the isostatic pressed green body is heated to 1050° C. in a sintering machine at a rate of 15° C. / h for sintering a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com