A kind of water-based polyurethane dipped gloves and production method thereof

A water-based polyurethane, production method technology, applied in gloves, protective clothing, clothing features and other directions, can solve the problems of inability to achieve the protective effect of the coating, the coating on the surface of the glove is easy to fall off, the structure is not strong, etc., to reduce energy consumption, The effect of improving product qualification rate and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

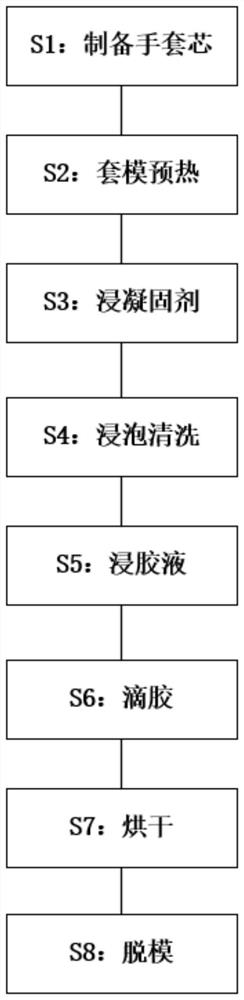

[0055] Step S1, preparing the glove core: using polyester-cotton blended material, and processing it into a glove blank by 10-pin, 13-pin, 15-pin or 18-pin knitting;

[0056] Step S2, mold preheating: put the knitted glove core on the hand mold, and preheat at 30-40°C for 30 minutes;

[0057] Step S3, soaking the coagulant: dipping the hand mold covered with the glove core into the coagulant, the coagulant is cleaned by a metal salt in 12 parts by weight of sodium chloride, potassium chloride, aluminum sulfate or magnesium sulfate Liquid, 1.5 parts of acrylic water-based adhesive, 2 parts of methanol and 84.5 parts of water;

[0058] Step S4, soaking and cleaning; soaking and cleaning the hand mold soaked in the coagulant, the solution used for soaking is pure water, and cleaning after soaking for 40 minutes;

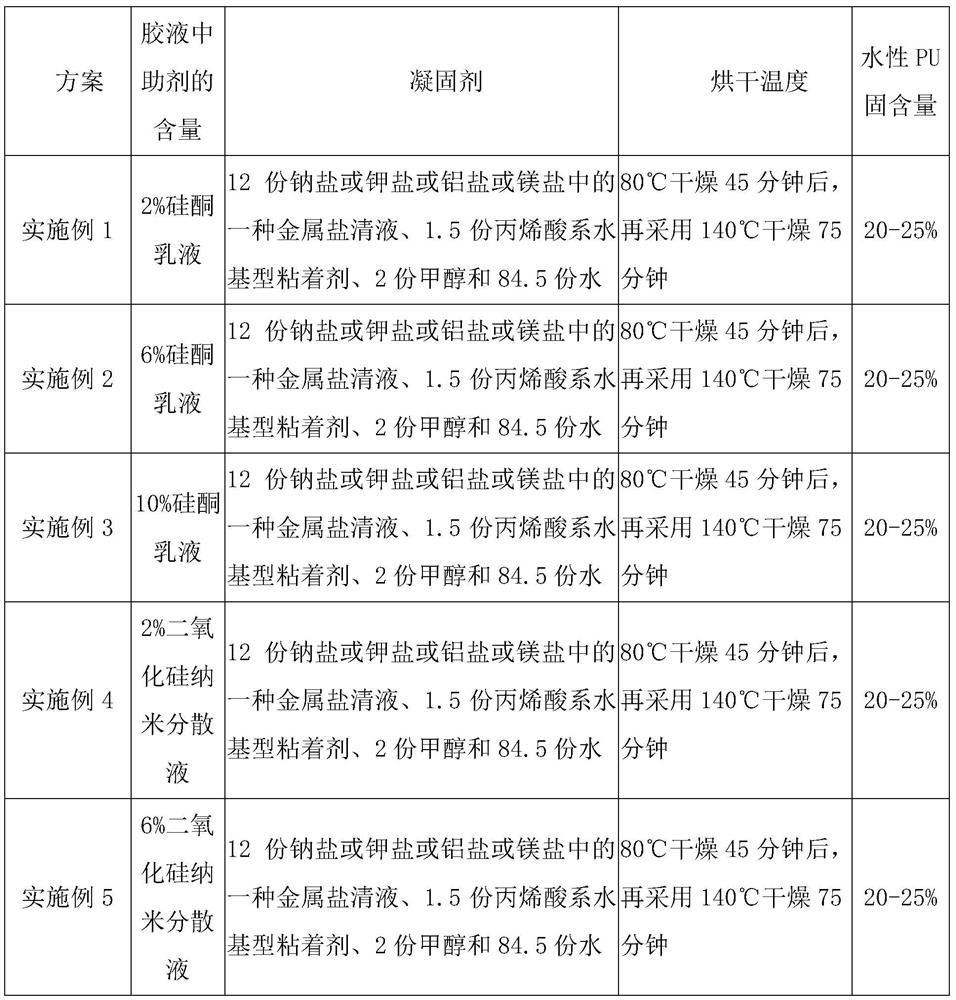

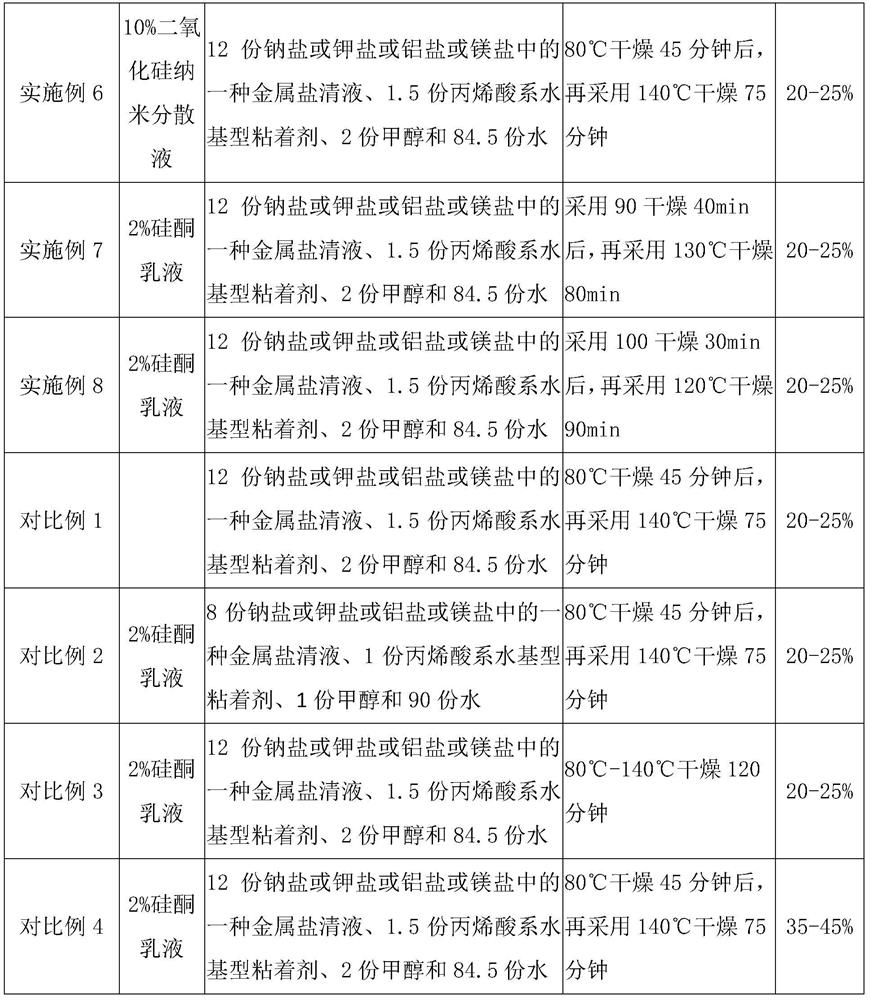

[0059]Step S5, dipping solution: immerse the hand mold in step S4 into the water-based polyurethane glue solution, the preparation of the water-based polyurethane glue...

Embodiment 2

[0064] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0065] Step S5, glue dipping solution: immerse the hand mold in step S4 into the water-based polyurethane glue liquid, the preparation of the water-based polyurethane glue liquid first stirs 94 parts of water-based polyurethane with a solid content of 25% and 6 parts of silicone emulsion Mix evenly and fully, and then use 3-5 parts of thickener and 10 parts of water to adjust the viscosity to 2000mpa.s.

Embodiment 3

[0067] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0068] Step S5, glue dipping solution: immerse the hand mold in step S4 into the water-based polyurethane glue solution, the preparation of the water-based polyurethane glue solution first stirs 90 parts of water-based polyurethane with a solid content of 25% and 10 parts of silicone emulsion Mix evenly and fully, and then use 3-5 parts of thickener and 10 parts of water to adjust the viscosity to 2000mpa.s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com