A kind of anti-fingerprint compound and its preparation method and application

A compound and anti-fingerprint technology, which is applied in the field of anti-fingerprint compounds and its preparation, can solve the problems of poor adhesion and scratch resistance and high production cost, and achieve low surface energy, good stability, good adhesion and scratch resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

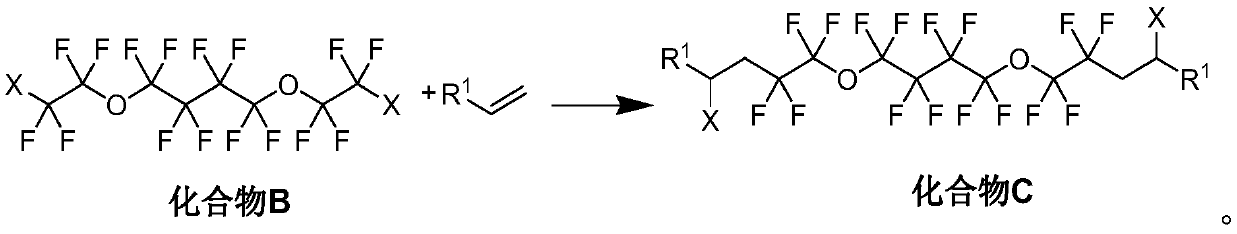

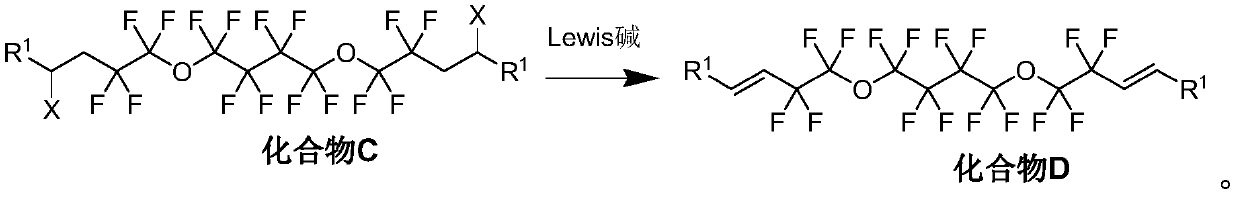

Method used

Image

Examples

Embodiment 1

[0077] A preparation method of an anti-fingerprint compound, comprising:

[0078] (1) Preparation of compound C1: In a 5-liter high-pressure reactor equipped with a mechanical stirrer, under a nitrogen atmosphere, add 2000 mL of acetonitrile and 3551 g (6.0 mol) of compound B1 while stirring 104g (1.4mol) of sodium dithionite (i.e. sodium hydrosulfite), 50g of sodium bicarbonate, 500mL of water, replaced by ethylene three times, then introduced ethylene, heated to a temperature of 50°C, reacted for 10h, and used 19 F NMR followed the progress of the reaction. After the reaction was finished, the obtained reaction solution was subjected to vacuum distillation to evaporate most of the solvent, and 2000 mL of water was added to the reaction system at a lower temperature, and the filtrate was obtained by filtration. 2000mL of saturated sodium sulfite aqueous solution and 2000mL of water were washed once respectively, after distillation to remove the extraction solvent, 2799g of ...

Embodiment 2

[0092] A preparation method of an anti-fingerprint compound, comprising:

[0093] (1) Preparation of Compound C1: see Example 1 above;

[0094] (2) Preparation of compound D1: see Example 1 above;

[0095] (3) Preparation of compound A2: In a 5-liter three-neck glass bottle equipped with a mechanical stirrer, after nitrogen replacement, under stirring conditions, add 2000mL of perfluoropolyether solvent (HT110), 1806g (3.71mol) of the compound D1, 12.8g (22.5mmol) of Karstedt's catalyst, heat the oil bath until the temperature in the glass bottle is between 60 and 70°C, then add 1687g (8.17mol) of triisopropoxysilane dropwise, and keep warm at this temperature The reaction was stirred for 12 hours, and the hydrogen spectrum was used to 1 H NMR detects the reaction progress. When the olefin peak in the hydrogen spectrum disappears, it means that the reaction of the system is completed, and then the post-treatment is carried out.

[0096] After the reaction, the reaction solu...

Embodiment 3

[0102] A preparation method of an anti-fingerprint compound, comprising:

[0103] (1) Preparation of compound C2: In a 5-liter three-neck flask equipped with a mechanical stirrer, under a nitrogen atmosphere, add 1500 mL of ethanol and 4115 g (6.0 mol) of compound B2 while stirring 73g (0.301mol) of benzoyl peroxide (BPO) was replaced with nitrogen three times, under the protection of nitrogen, 1375g (13.2mol) of freshly distilled styrene was added dropwise, heated to a temperature of 80-90°C, and reacted for 5 hours. After the reaction finished, the gained reaction solution was cooled and filtered to obtain the filtrate, first the gained filtrate was subjected to vacuum distillation to remove the solvent, then 1500mL of dichloromethane was added for dissolving, and the gained organic phase was washed twice with 2000mL×2 tap water (with Remove impurities such as water-soluble inorganic salts), then wash once with 1500mL saturated aqueous sodium sulfite solution, distill under...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com