Preparation method for cuprous oxide coated molding carbon material

A cuprous oxide and overmolding technology, which is applied in biochemical fuel cells, final product manufacturing, sustainable manufacturing/processing, etc., can solve the difficulty of controlling particle layer density and thickness, high energy costs and raw material costs, and raw material loss rate Advanced problems, to achieve the effects of mass production, stable film forming effect, and high current utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

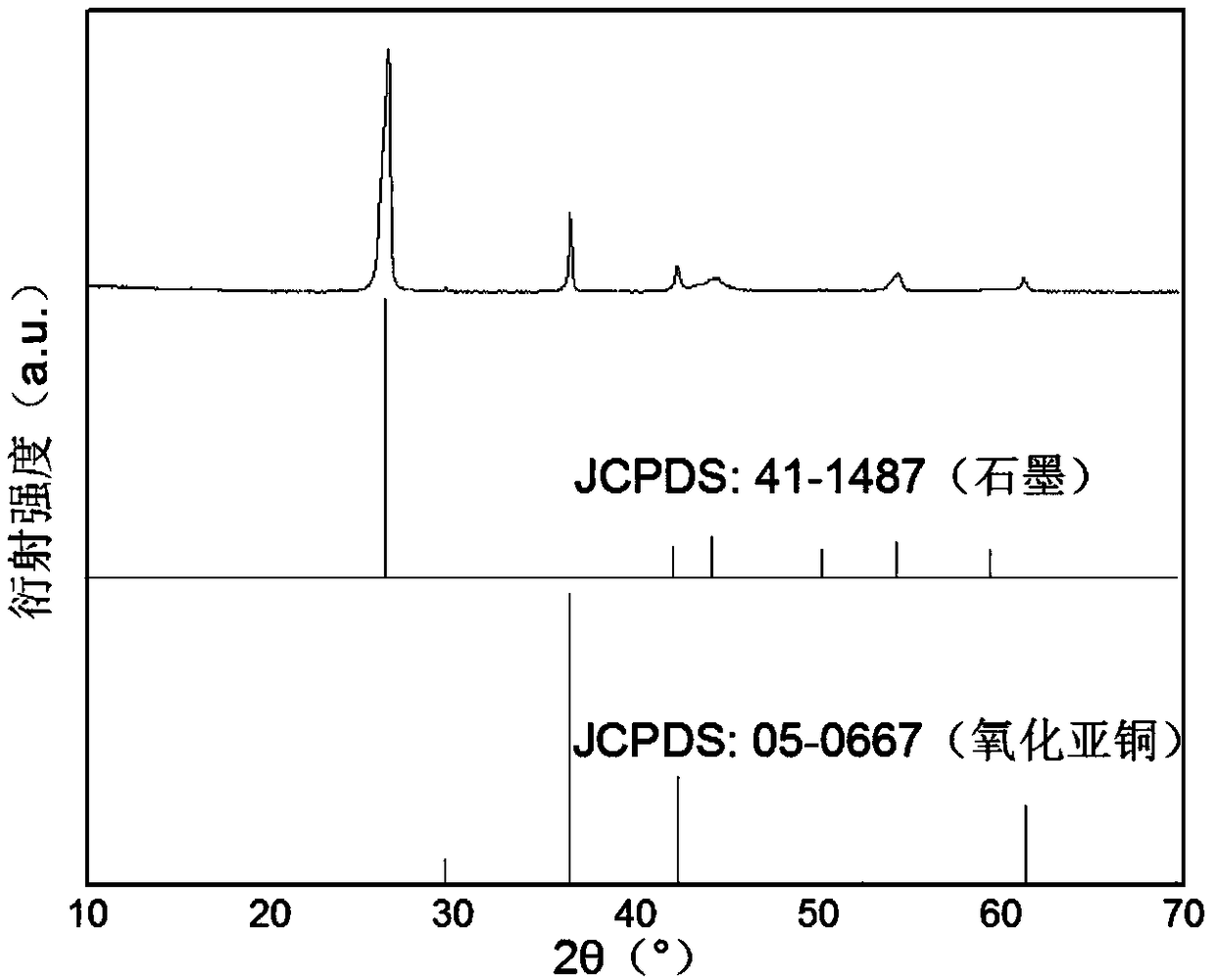

[0032] Cuprous oxide coated graphite plate electrode preparation:

[0033] Cut the high-temperature pyrolytic graphite plate into an area of 4cm 2 The square of the high-temperature pyrolytic graphite plate is polished to smooth with P400 sandpaper, P1500 sandpaper and 0.05μm aluminum powder in sequence, except for one area of 4cm 2 Paste the other sides of the graphite board with waterproof insulating tape. Suspend a piece of electrode in 50mL of a mixed solution of 0.1M copper nitrate and 3M lactic acid with pH=12.0, T=40℃, and the exposed surface is 9cm in area. 2 A square platinum sheet with an electrode spacing of 2 cm. Connect the graphite plate to the working electrode of the electrochemical workstation, connect the platinum plate to the reference electrode and the counter electrode, and construct a two-electrode electrolytic cell system. Send 1mA·cm to the working electrode -2 The current (the total current is calculated according to the exposed area of the g...

specific Embodiment 2

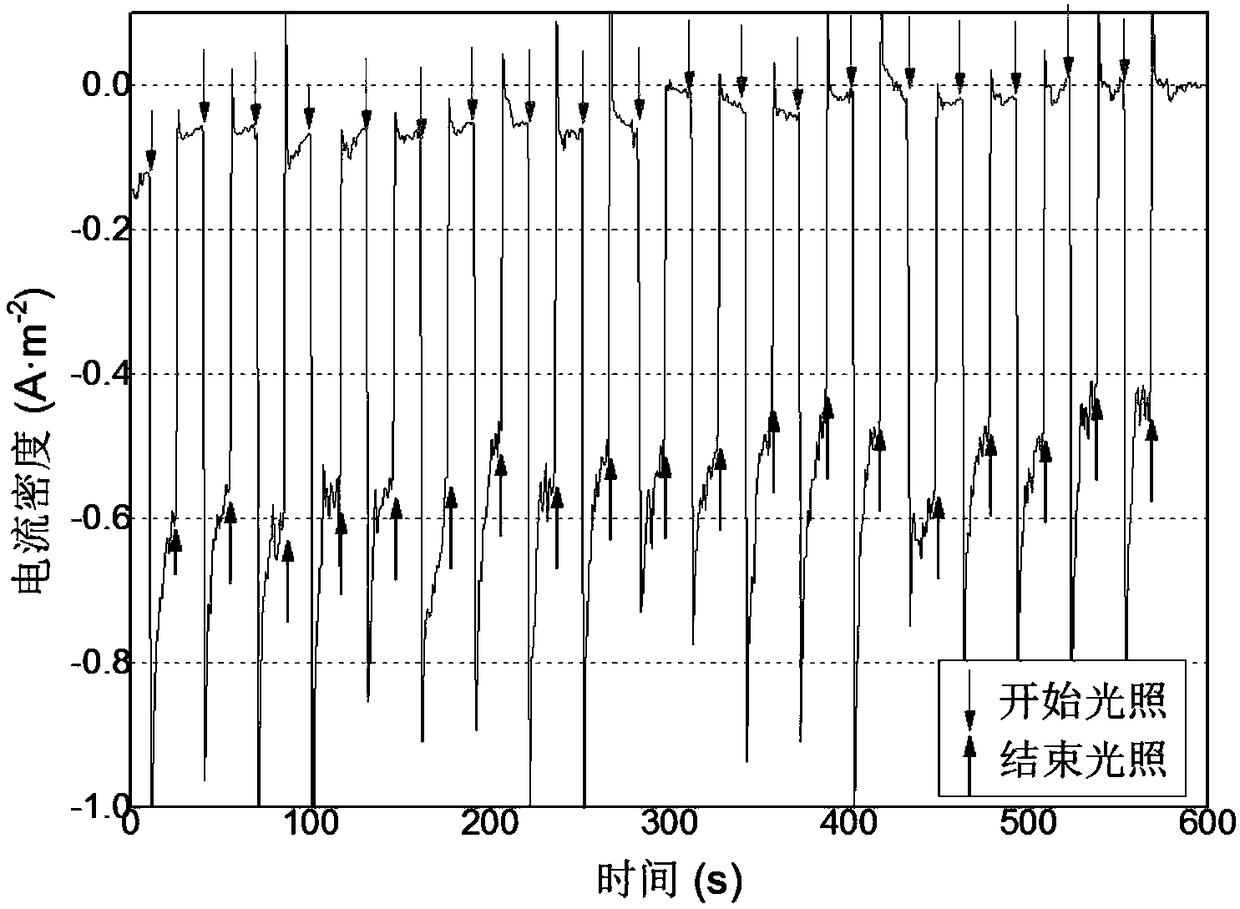

[0037] Cuprous oxide-coated graphite plate electrodes with different electrodeposition times were prepared for multiple samples:

[0038] Cut the high-temperature pyrolytic graphite plate into 4 pieces with an area of 4cm 2 square, and perform the following treatment: use P400 sandpaper, P1500 sandpaper and 0.05μm aluminum powder to polish all sides of the high-temperature pyrolytic graphite plate until smooth, except for one area of 4cm 2 Paste the other sides of the graphite board with waterproof insulating tape. Suspend a piece of electrode in 50mL of a mixed solution of 0.1M copper nitrate and 3M lactic acid with pH=12.0, T=40℃, and the exposed surface is 9cm in area. 2 A square platinum sheet with an electrode spacing of 2 cm. Connect the graphite plate to the working electrode of the electrochemical workstation, connect the platinum plate to the reference electrode and the counter electrode, and construct a two-electrode electrolytic cell system. Send 1mA·cm to th...

specific Embodiment 3

[0042] Except for the following adjusted parameters, the preparation method of the cuprous oxide overmolded carbon material in this embodiment is the same as that in Example 1, and the adjusted specific parameters are:

[0043] Graphite rods are used as the base material, and a mixed solution of 0.2M copper nitrate and 4M acetic acid with pH=9.0 and T=60°C is used as the electrolyte solution, at 0.5mA·cm -2 The current density was reduced for 2 hours, rinsed with deionized water for 4 times, soaked in deionized water for 20 minutes, wrapped with aluminum foil, and dried in vacuum at 60°C for 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com