High-strength pipeline steel for petroleum and manufacturing method of pipeline steel

A high-strength, pipeline steel technology, applied in the field of metal materials, can solve the problems of disclosure of chemical composition and its production method, large anisotropy of hot-rolled sheets, and large performance changes, so as to save the heat treatment process and increase the strength. The effect of large and thin pipe wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

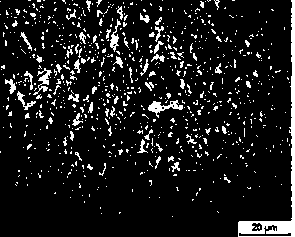

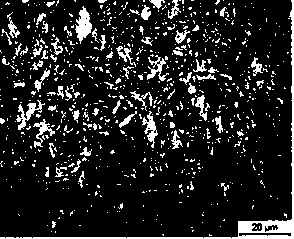

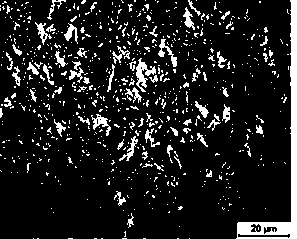

Image

Examples

Embodiment 1

[0051] (1) KR hot metal pretreatment desulfurization: oxygen blowing time is 15min, oxygen supply intensity is 18000m3 / h, sulfur content in hot metal after treatment is ≤0.005%;

[0052] (2) Converter smelting: Double slag operation is adopted, the bottom blowing of the converter adopts an automatic model, when the carbon content is 0.18%, the blowing is supplemented once, the carbon content target is ≤0.055%, the phosphorus content is ≤0.015%, and the tapping temperature is 1600°C; Slag plug, slag blocking rod double slag blocking tapping; 1050kg of lime and 230kg of fluorite are added to make top slag during tapping;

[0053] (3) LF+RH refining process: LF white slag treatment, slag target composition: CaO50%, SiO230%, Al2O315%, MgO5%, FeO+Fe2O3+MnO≤1.0%, vacuum degree≤2mbar; vacuum treatment time 22 minutes ;

[0054] (4) Continuous casting process: argon blowing protection throughout the process to avoid oxidation of molten steel and control nitrogen increase in the conti...

Embodiment 2

[0058] (1) KR hot metal pretreatment desulfurization: oxygen blowing time is 15min, oxygen supply intensity is 18000m3 / h, sulfur content in hot metal after treatment is ≤0.005%;

[0059] (2) Converter smelting: Double slag operation is adopted, the bottom blowing of the converter adopts an automatic model, when the carbon content is 0.18%, supplementary blowing is performed once, the carbon content target is ≤0.055%, the phosphorus content is ≤0.015%, and the tapping temperature is 1600°C; Slag plug, slag blocking rod double slag blocking tapping; 1050kg of lime and 230kg of fluorite are added to make top slag during tapping;

[0060] (3) LF+RH refining process: LF white slag treatment, slag target composition: CaO50%, SiO230%, Al2O315%, MgO5%, FeO+Fe2O3+MnO≤1.0%, vacuum degree≤2mbar; vacuum treatment time 22 minutes ;

[0061] (4) Continuous casting process: use a protective cover, implement argon blowing protection throughout the process, avoid oxidation of molten steel, an...

Embodiment 3

[0065] (1) KR hot metal pretreatment desulfurization: oxygen blowing time is 15min, oxygen supply intensity is 18000m3 / h, sulfur content in hot metal after treatment is ≤0.005%;

[0066] (2) Converter smelting: Double slag operation is adopted, the bottom blowing of the converter adopts an automatic model, when the carbon content is 0.18%, supplementary blowing is performed once, the carbon content target is ≤0.055%, the phosphorus content is ≤0.015%, and the tapping temperature is 1600°C; Slag plug, slag blocking rod double slag blocking tapping; 1050kg of lime and 230kg of fluorite are added to make top slag during tapping;

[0067] (3) LF+RH refining process: LF white slag treatment, slag target composition: CaO50%, SiO230%, Al2O315%, MgO5%, FeO+Fe2O3+MnO≤1.0%, vacuum degree≤2mbar; vacuum treatment time 22 minutes ;

[0068] (4) Continuous casting process: use a protective cover, implement argon blowing protection throughout the process, avoid oxidation of molten steel, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com