High power LED lamp heat conducting and heat radiating device, heat conducting base and producing technique

A technology of LED lamps and manufacturing process, which is applied to cooling/heating devices of lighting devices, lighting devices, semiconductor devices, etc., and can solve the problems of not having a protective layer, affecting the heat conduction speed of the heat conduction base, and large volume, etc., to achieve expanded application Range, improved heat dissipation effect, high thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

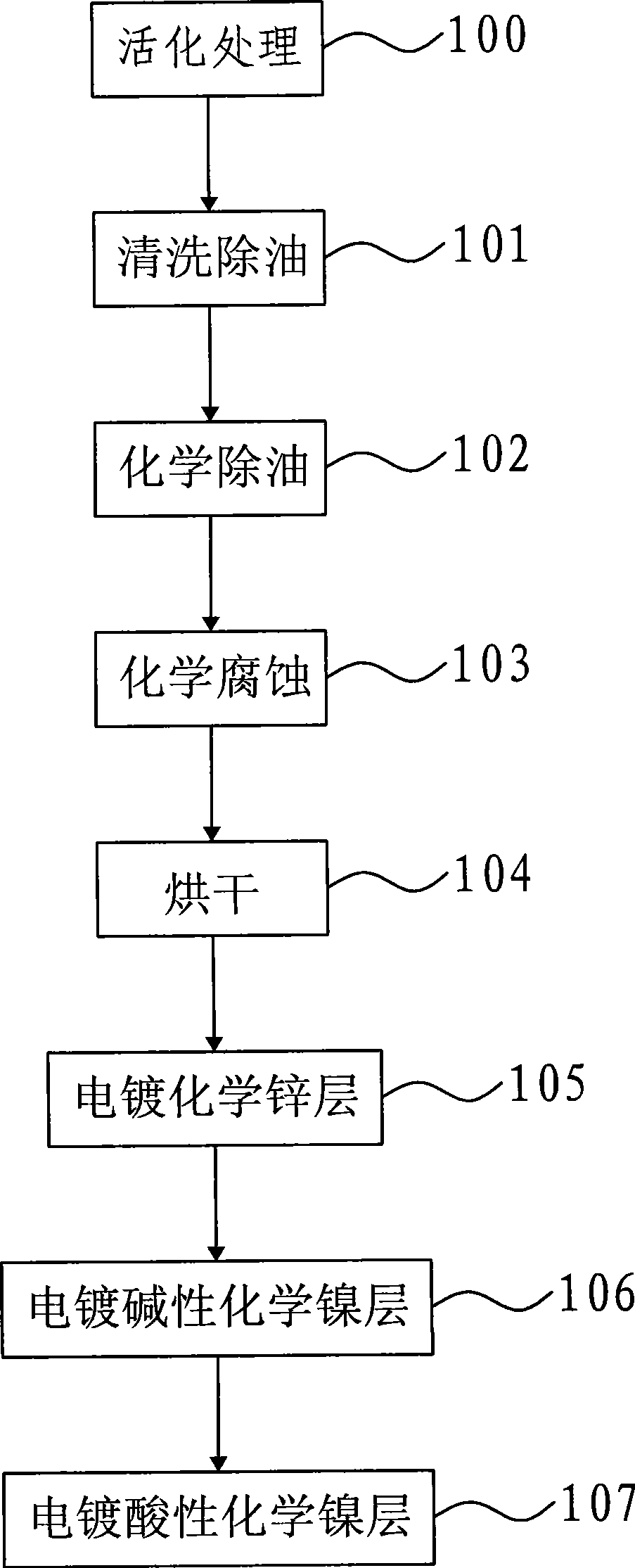

[0041] Below in conjunction with accompanying drawing, the present invention will be further described, please refer to figure 1, is graphite surface electroplating manufacturing process of the present invention. As shown in step activation treatment 100, first the processed graphite product is put into the activation treatment solution for soaking, that is, the graphite product has been cut into shape or punched according to the requirements, and then soaked in the activation treatment solution to control the degree of immersion. Time is 10~15 minutes, until the surface of graphite product is gray ink color; Wherein, the composition of the activation treatment solution of the present embodiment is: nickel sulfate 24~30g / L, hydroxyethylidene diphosphonic acid 40~50g / L, Stabilizer 25~30mL / L, surplus is water; Described activation treatment liquid is under normal temperature (being 25 ℃), adjusts pH value with sodium hydroxide solution and is greater than 12; The stabilizer of t...

Embodiment 2

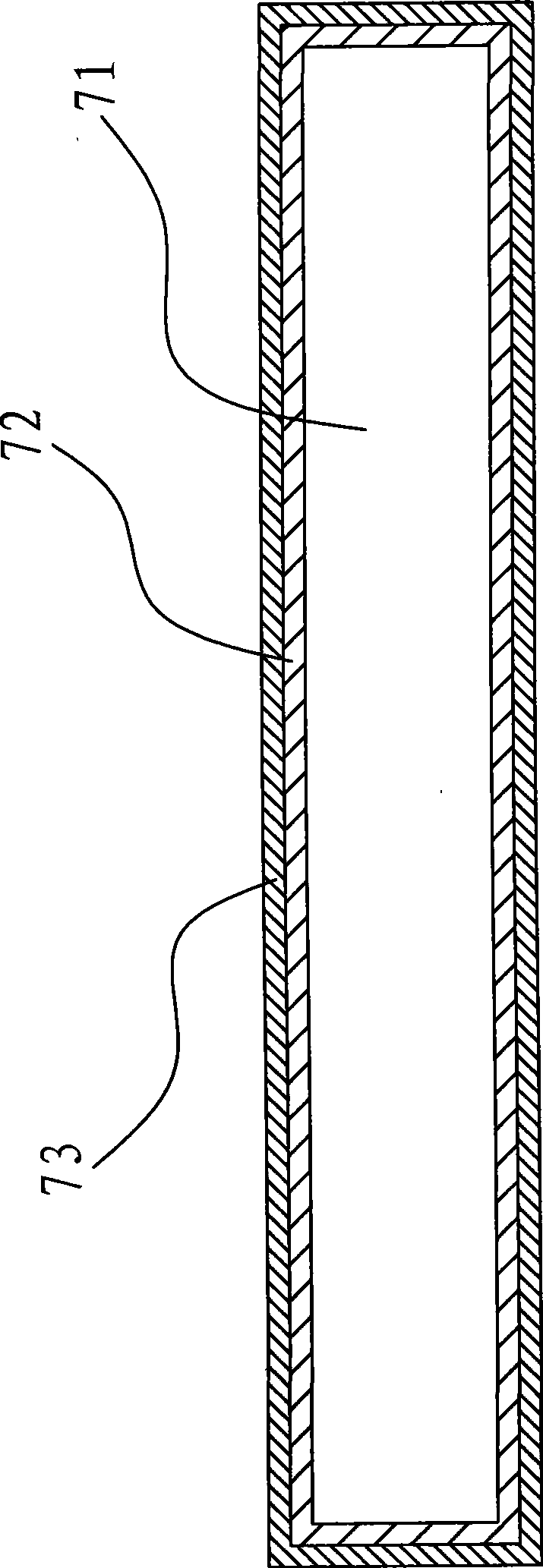

[0050] Please refer to figure 2 , is the graphite thermal conduction base that the present invention adopts the graphite surface electroplating manufacturing process of embodiment one to make, and it comprises graphite product 71, and the surface electroplating of described graphite product 71 has a chemical zinc layer 72, and the surface electroplating of chemical zinc layer 72 There is an chemical nickel layer 73; wherein, the chemical zinc layer 72 and the chemical nickel layer 73 are all formed on the surface of the graphite product 71 in the mode of electroless plating, and the effect of the chemical zinc layer 72 is to increase the adhesive force of the graphite product 71 surface, so that The outermost chemical nickel layer 73 can have good adhesion; because the chemical zinc layer 72 and the chemical nickel layer 73 electroplated on the graphite product 71 surface are all very thin, and the thickness of the chemical nickel layer 73 is 25~30 microns, so The chemical zi...

Embodiment 3

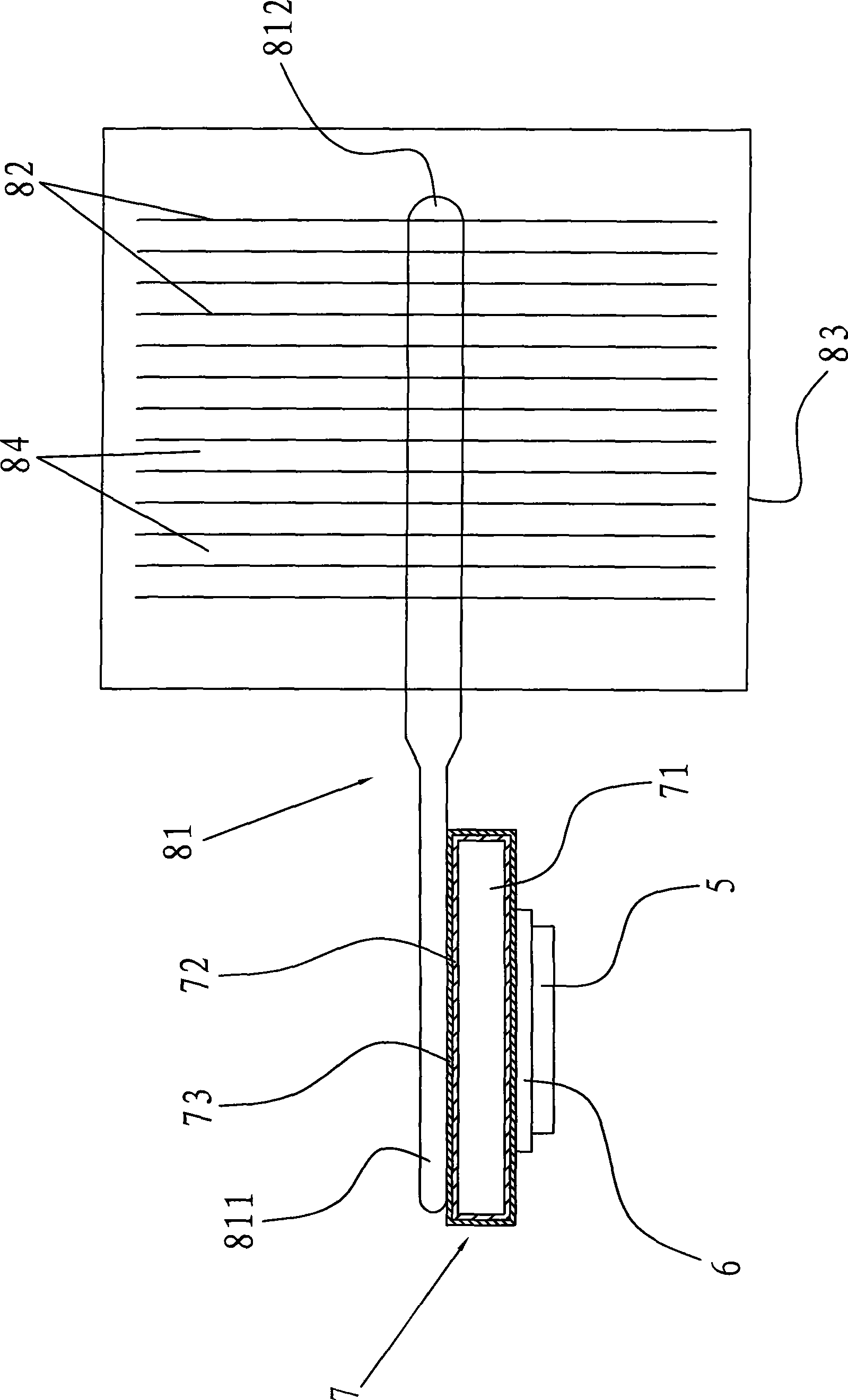

[0052] Please refer to image 3 , for the present invention adopts the heat conduction and heat dissipation device of the high-power LED lamp of the above-mentioned embodiment 2 graphite heat conduction base, it comprises above-mentioned graphite heat conduction base 7, heat dissipation device, graphite heat conduction base 7 is fixed on the heat conduction substrate 6 of LED lamp The top of the heat sink is fixed on the top of the graphite heat conduction base 7; according to the above description, the graphite heat conduction base 7 includes a graphite product 71, and the surface of the graphite product 71 is electroplated with a chemical zinc layer 72, and the surface of the chemical zinc layer 72 is electroplated There is an chemical nickel layer 73, wherein, the chemical zinc layer 72 and the chemical nickel layer 73 are all formed on the surface of the graphite product 71 by means of electroless plating, and the effect of the chemical zinc layer 72 is to increase the adhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com