A kind of rapidly crystallized pbat material and preparation method thereof

A crystallization and rapid technology, applied in the field of biodegradable polymer material modification, can solve the problems of inability to increase the crystallization temperature and crystallization speed of PBAT materials, and achieve the effects of easy large-scale industrial production, improved processing efficiency, and improved mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of the PBAT material with faster crystallization rate among the present invention comprises the following steps:

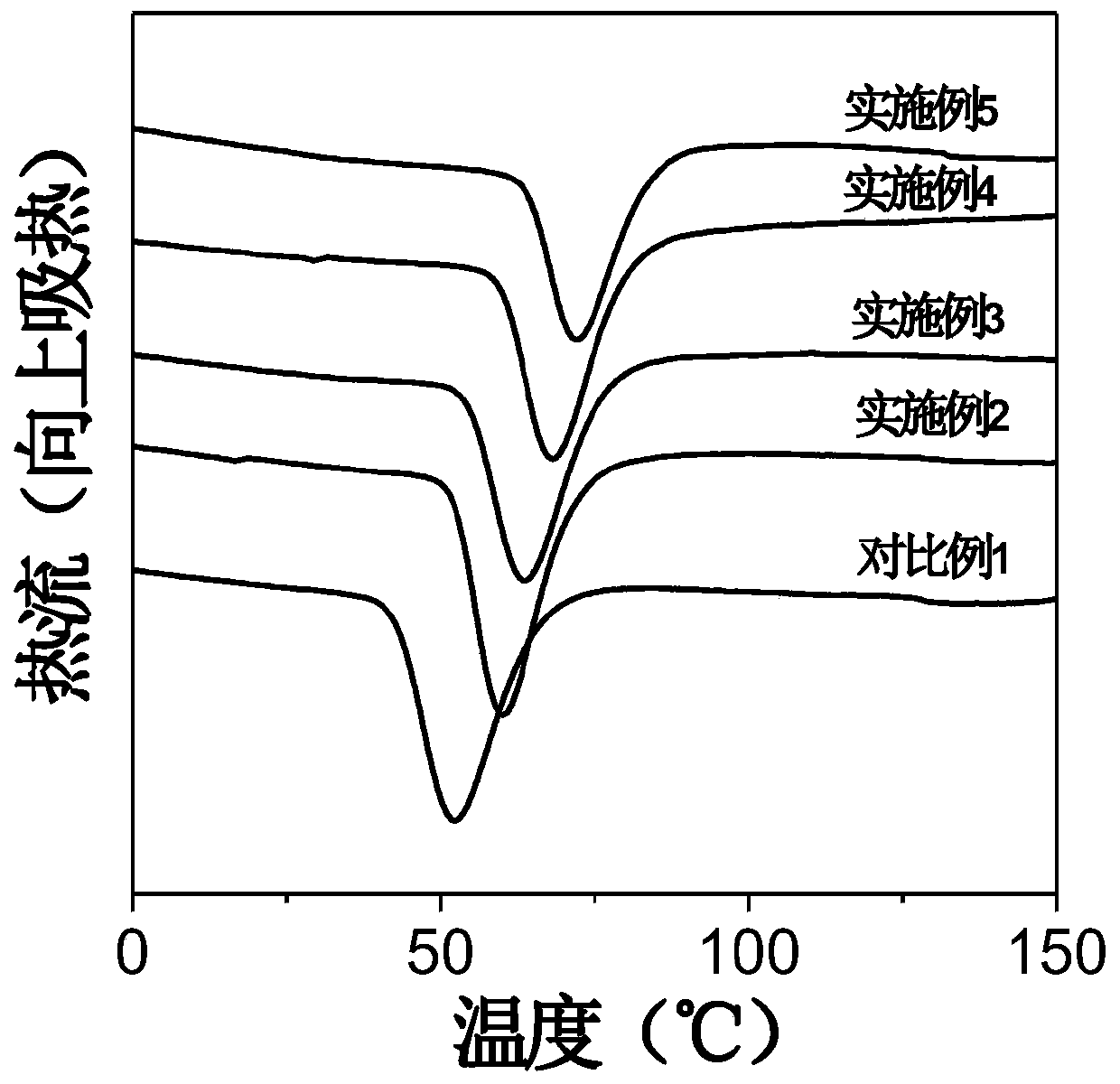

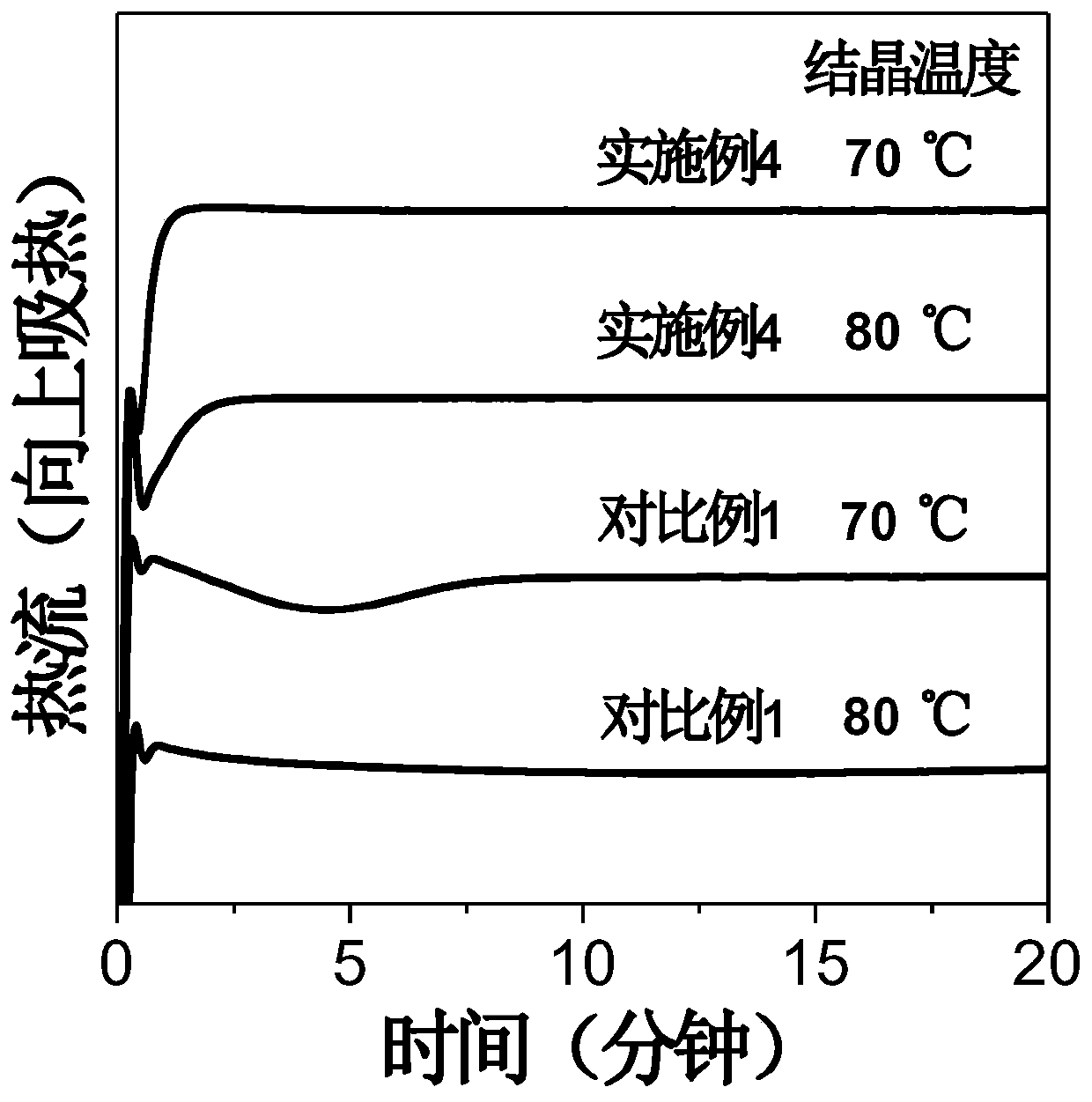

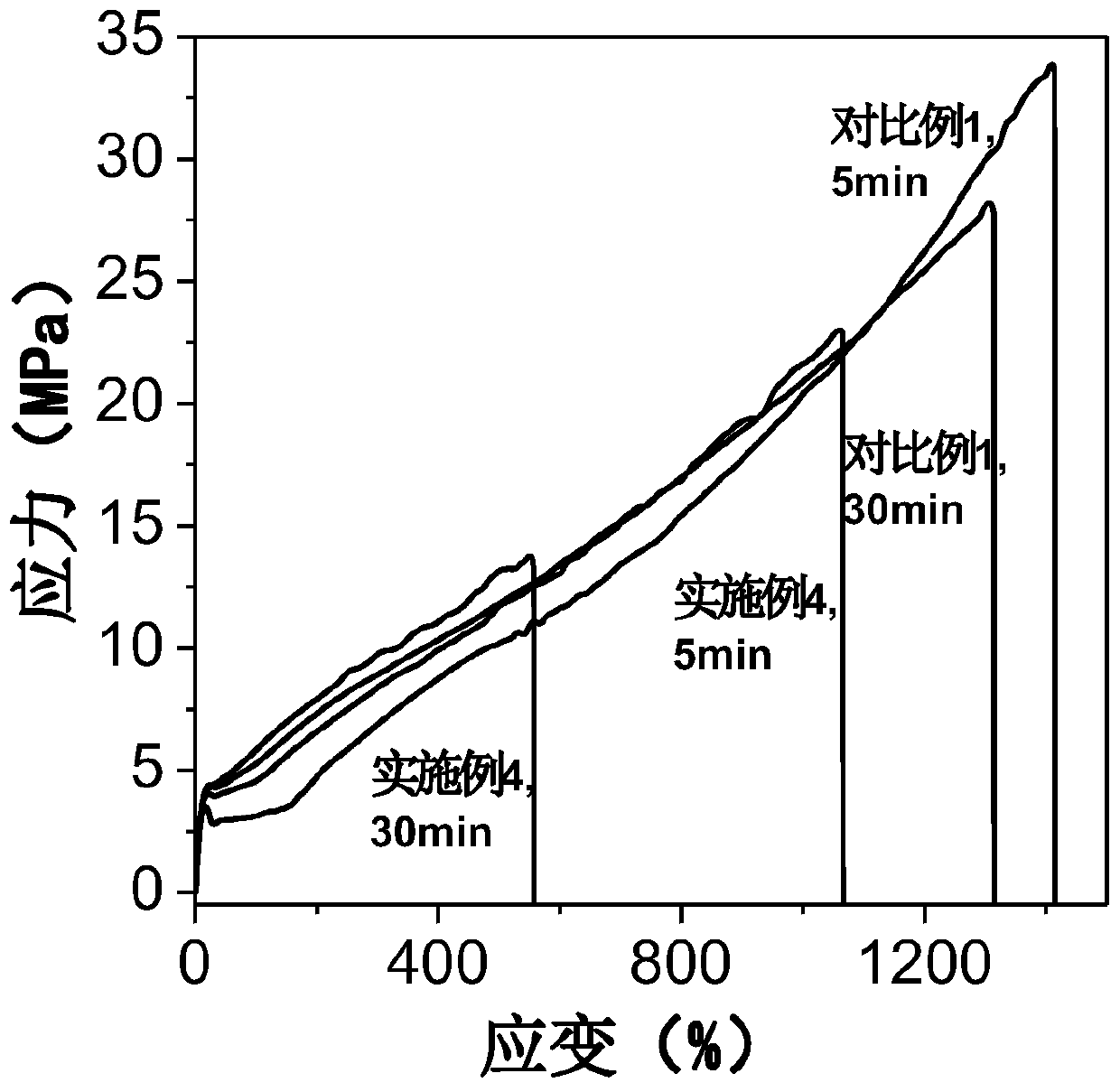

[0029] The PBAT material is obtained by blending polyadipate / butylene terephthalate (PBAT) and melamine / cyanuric acid complex as a nucleating agent through solution or melt method. Wherein, the mass percent content of the nucleating agent in the final product is 0.05%-5%.

[0030] The solution method blending means that the nucleating agent and PBAT are dissolved in chloroform or dichloromethane, so that the concentration of the polymer is 50g / L; after stirring at room temperature to dissolve the polymer and mix it uniformly, the polymer solution is cast In a polytetrafluoroethylene petri dish; the solvent was completely evaporated at room temperature, and then the polytetrafluoroethylene petri dish was dried in a vacuum oven at 60°C for 6 hours to obtain a PBAT material with a faster crystallization rate.

[0031] The melt blending ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com