Heat-insulation and decoration integrated structure and preparation technique thereof

A preparation process and integrated board technology, which is applied in building construction, other household appliances, applications, etc., to achieve the effects of increasing adhesion, good waterproof performance, and eliminating efflorescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The raw materials for preparing the imitation stone facing layer include the following components in parts by weight:

[0039]

[0040] The colored natural stone aggregate is a powder processed from natural stone through multiple processes such as crushing, cleaning, and screening. It has good weather resistance, acid and alkali resistance, and non-fading properties, and is non-artificially sintered colored sand. The particle size of the aggregate is used in combination with coarse and fine particles, which is not easy to affect the decorative effect of the coating, and can also make the coating dense; the color of the aggregate can be selected according to the needs. The binder is Portland cement, and the additives are conventional additives such as waterproofing agent and thickener, which can be selected according to needs; the solvent is water.

Embodiment 1

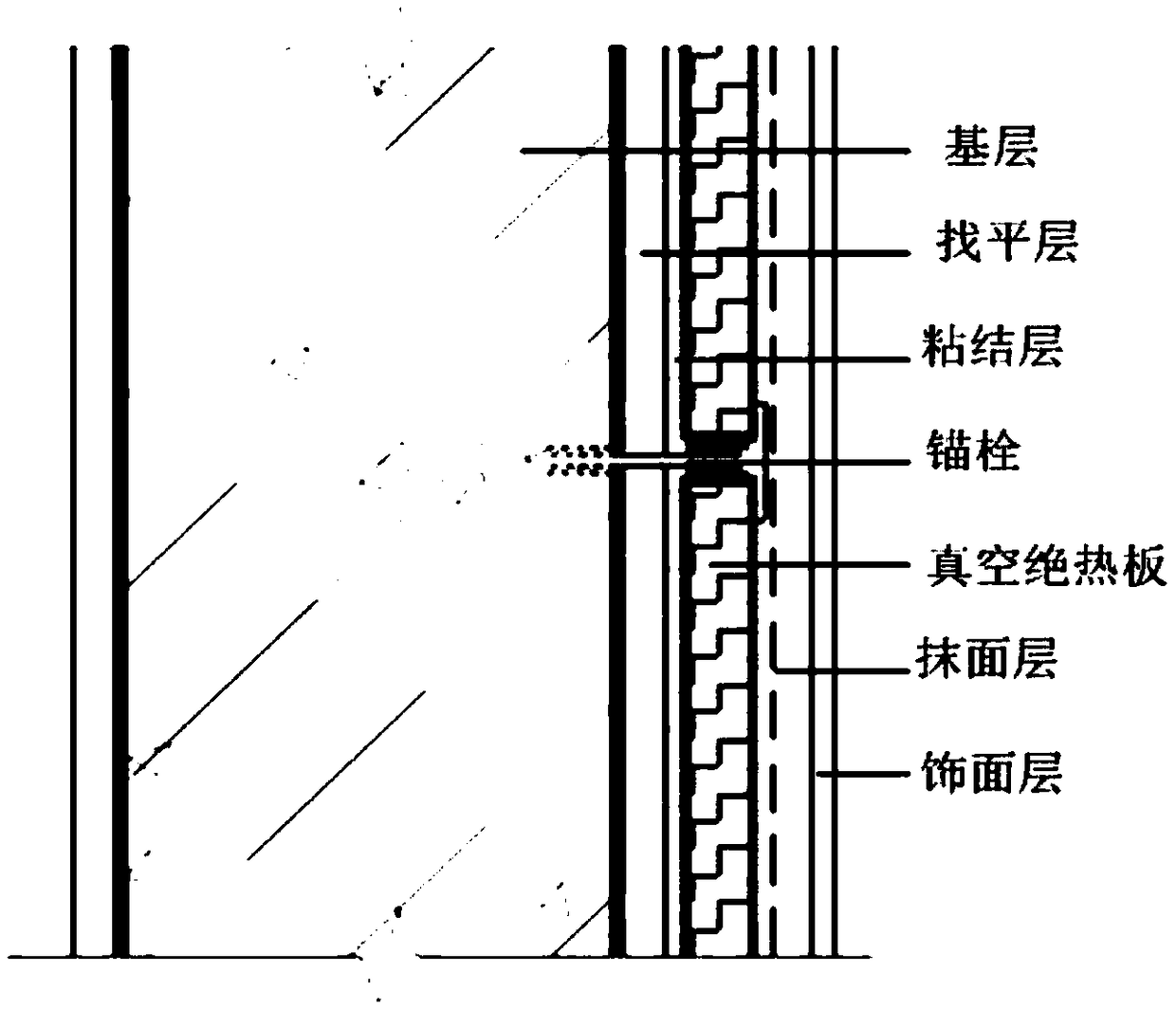

[0042]The preparation process of the thermal insulation and decoration integrated board structure in this embodiment includes the following steps:

[0043] (1) Preparation of vacuum insulation panels: Composite the core material of the vacuum insulation panels with the composite gas barrier layer. The baking time is 2 minutes, so that the PE layer and the core material are tightly bonded without loosening.

[0044] (2) Preparation of primer:

[0045] Using the roller coating method, roll-coat the silicon-acrylic emulsion on the glass fiber cloth of the composite gas barrier layer, and dry it at room temperature for 12 hours to obtain the primer layer. 2 The weight of the silicone-acrylic emulsion coated on the glass fiber cloth per square meter is 0.15-0.20kg.

[0046] (3) Prepare imitation stone facing layer:

[0047] Choose colored natural stone aggregates, choose aggregates with particle size grades of 0.1-0.15mm and 0.3-0.4mm, and mix them evenly. The raw materials for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com