Simple preparation method for nano-grade tungsten-copper precursor powder

A precursor powder and nano-scale technology, applied in the direction of nanotechnology, can solve the problems of long production cycle and high energy consumption, and achieve the effects of shortened production cycle, reduced energy consumption, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

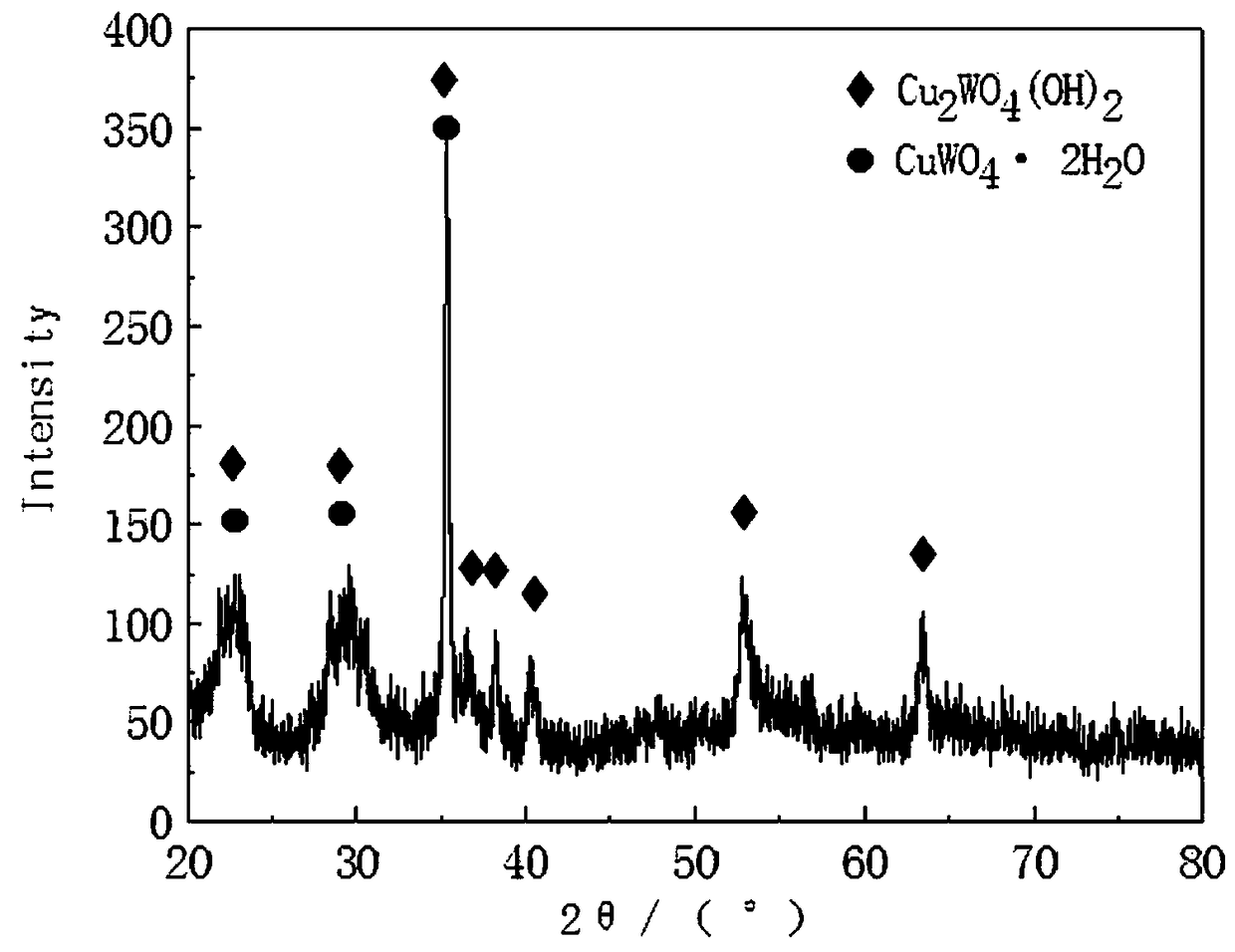

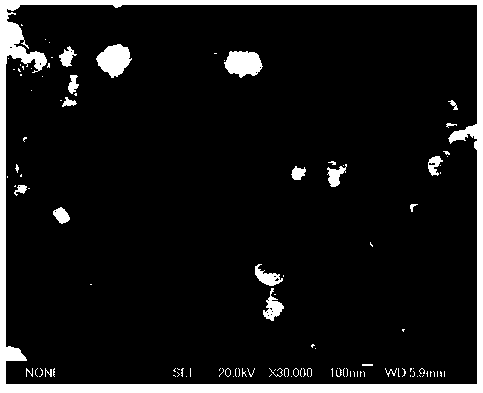

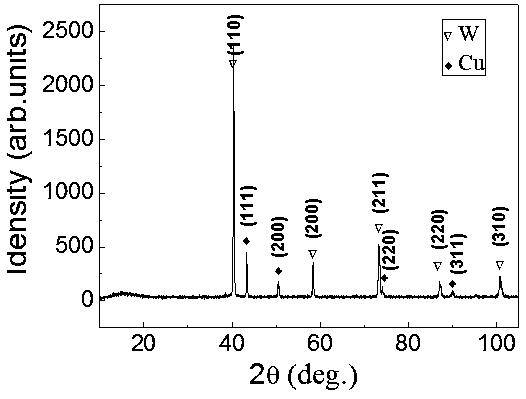

Image

Examples

Embodiment 1

[0027] A simple preparation method of nano-scale tungsten-copper precursor powder adopts the following production steps:

[0028] Step 1. According to the mass percentage of W in the target composite powder is 50-60%, and the mass percentage of Cu is 40-50%, weigh sodium tungstate dihydrate and copper nitrate trihydrate, and prepare them respectively to a concentration of 0.8 mol / L solution;

[0029] Step 2, adding excessive ammoniacal liquor to the obtained copper nitrate trihydrate solution, and making it fully mixed at 30°C, so that sufficient copper complex ions are produced in the solution, and the ammoniacal liquor can be added in excess of 3-5%;

[0030] Step 3: Drop sodium tungstate solution into the solution obtained in Step 2 at a rate of 1~3 drops / s, then add ammonia water or nitric acid to adjust the pH value of the mixed solution to 4.0~6.2, and mix it in a magnetic stirrer at 60r / min speed fully stirred for 5h;

[0031] Step 4. Put the mixed solution obtained ...

Embodiment 2

[0035] A simple preparation method of nano-scale tungsten-copper precursor powder adopts the following production steps:

[0036] Step 1. According to the mass percentage of W in the target composite powder is 60-70%, and the mass percentage of Cu is 30-40%, weigh sodium tungstate dihydrate and copper nitrate trihydrate, and prepare them respectively to a concentration of 0.6 mol / L solution;

[0037] Step 2, adding excessive ammoniacal liquor to the obtained copper nitrate trihydrate solution, and making it fully mixed at 30°C, so that sufficient copper complex ions are produced in the solution, and the ammoniacal liquor is added in excess of 5-8%;

[0038] Step 3: Drop sodium tungstate solution into the solution obtained in Step 2 at a rate of 3~5 drops / s, then add ammonia water or nitric acid to adjust the pH value of the mixed solution to 4.0~6.2, and mix it in a magnetic stirrer at 60r / min speed fully stirred for 4h;

[0039] Step 4. Put the mixed solution obtained in S...

Embodiment 3

[0043] A simple preparation method of nano-scale tungsten-copper precursor powder adopts the following production steps:

[0044] Step 1. According to the mass percentage of W in the target composite powder is 70-80%, and the mass percentage of Cu is 20-30%, weigh sodium tungstate dihydrate and copper nitrate trihydrate, and prepare them respectively to a concentration of 0.4 mol / L solution;

[0045] Step 2, adding excessive ammoniacal liquor to the obtained copper nitrate trihydrate solution, and making it fully mixed at 30°C, so that sufficient copper complex ions are produced in the solution, and the ammoniacal liquor is excessively 8 to 10% when added;

[0046] Step 3: Drop sodium tungstate solution into the solution obtained in Step 2 at a rate of 5-8 drops / s, then add ammonia water or nitric acid to adjust the pH value of the mixed solution to 4.0-6.2, and mix it in a magnetic stirrer at 60r / min speed fully stirred for 3h;

[0047] Step 4. Put the mixed solution obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com