Compound chromate-free passivator capable of forming films rapidly and preparation method

A chromium-free passivation agent and film-forming technology, which is applied in the coating process of metal materials, etc., can solve the adverse effects of the combination of the coating and the metal plate, the passivation performance of the chromium-free passivation solution is unknown, and the coating is difficult for the metal plate to be firm Combination and other issues, to achieve good shielding protection, enhance the binding force and corrosion resistance, enhance the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

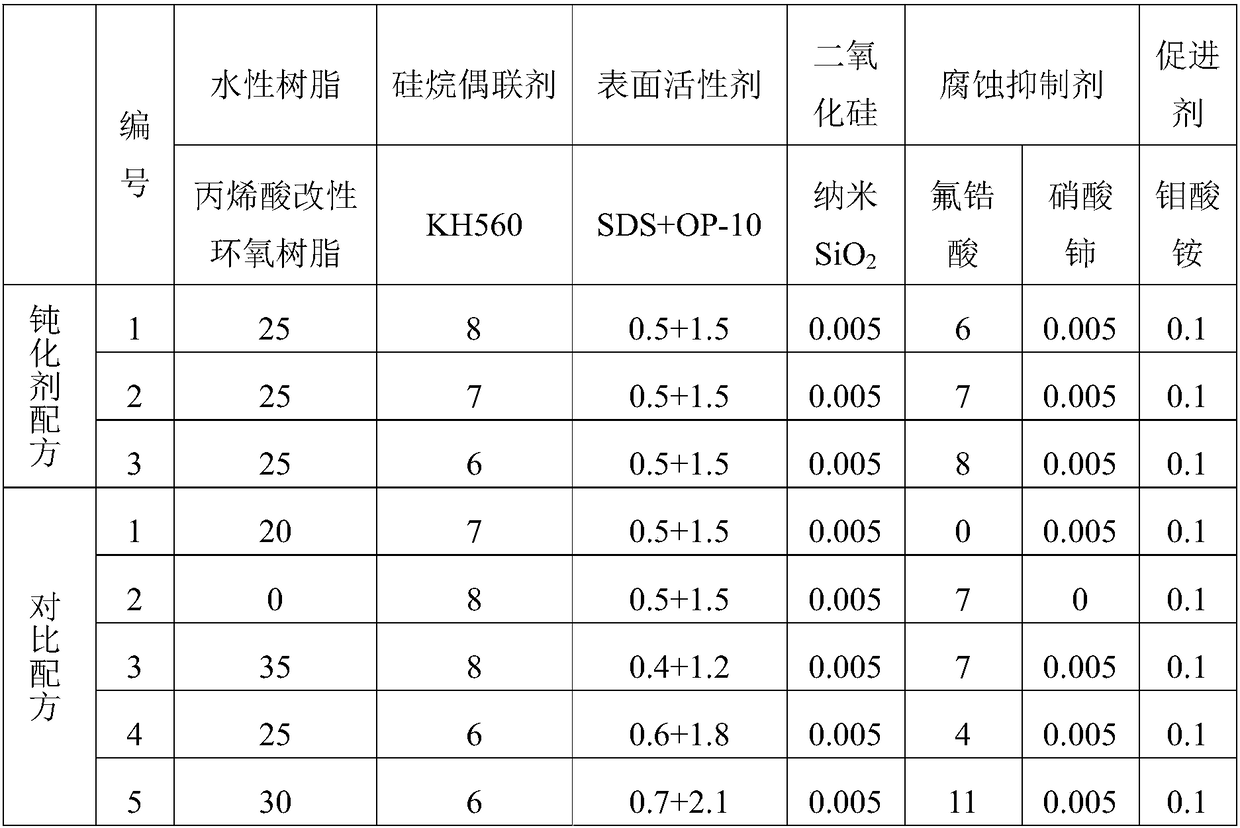

[0037] This example provides three formulations of fast-film-forming composite chromium-free passivators and five comparative formulations, as shown in Table 1.

[0038] Table 1 formula concrete component and content (mass percentage, balance is water)

[0039]

Embodiment 2

[0041] The present embodiment provides the preparation method of the compound chromium-free passivating agent of rapid film formation, comprises the following steps:

[0042] (1) Weigh each component according to the proportion, first add part of water into the reaction kettle, then add water-based resin, surfactant, corrosion inhibitor and accelerator in sequence, and stir until the liquid becomes clear;

[0043] (2) Add a silane coupling agent to the solution in step (1), fully stir until the liquid becomes clear, and the stirring time is >2h;

[0044] (3) Add silicon dioxide to the liquid in step (2), and stir until the liquid turns into a clear colloid.

Embodiment 3

[0046]Adopt the preparation method that embodiment 2 provides and the prescription of embodiment 1, prepared the passivating agent of corresponding numbering, compared the metal material sample after these passivating agent processing and the sample (galvanized) without passivating agent processing Plate) corrosion resistance results, the number of the style corresponds to the number of the passivating agent formula, and the results are shown in Table 2. The technological process of metal surface treatment is: degreasing→water washing→water washing→passivation→water washing→drying→post-treatment, using dipping or spraying treatment, the mass concentration of passivation solution is 3-5%, and the pH value of the working solution is 5.0~7.5, the treatment temperature is 10~40℃, and the treatment time is 0.5~3min. Neutral salt spray test uses salt spray of neutral NaCl solution to accelerate corrosion, adopts the method of continuous spraying to carry out the test according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com