Antirust and anticorrosive fitness equipment primer and preparation method thereof

A fitness equipment and anti-corrosion technology, which is applied in the direction of anti-corrosion coatings, coatings, epoxy resin coatings, etc., can solve the problems of not being able to play a good role in anti-rust, greater harm to operators, and difficulty in removing greasy, etc., to achieve good Rust removal effect, good water removal effect, good anti-rust and anti-corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

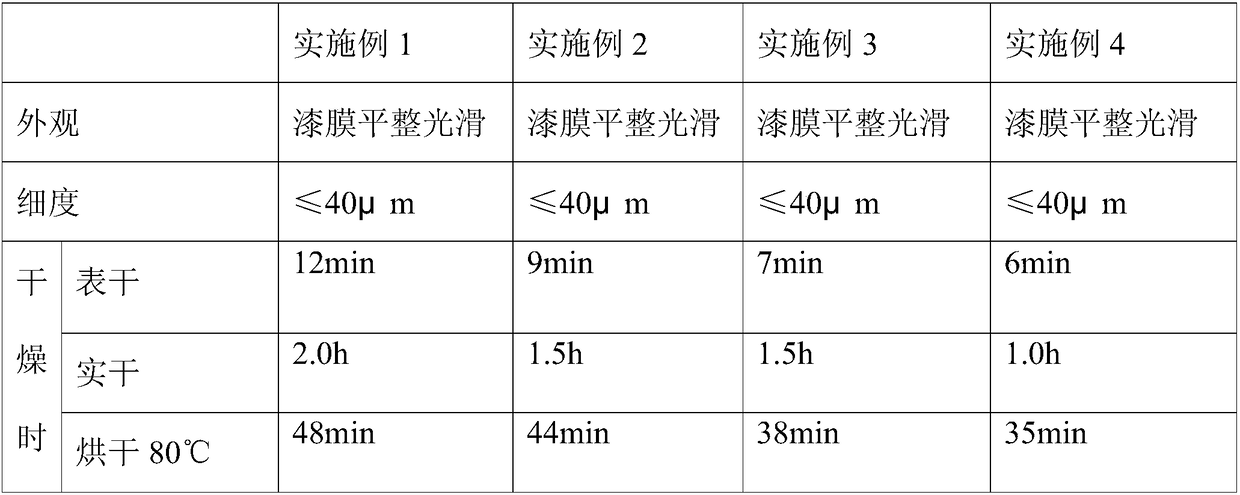

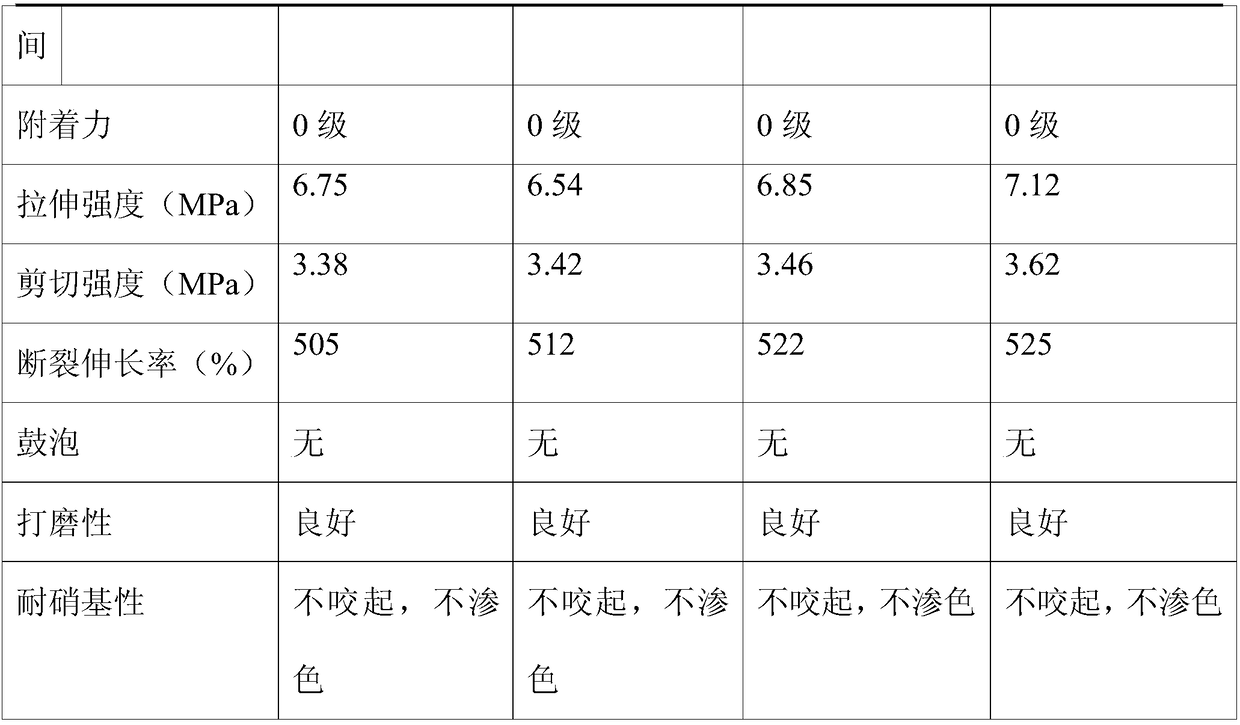

Examples

Embodiment 1

[0034] A kind of antirust and anticorrosion fitness equipment primer, this antirust and anticorrosion fitness equipment primer comprises A component and B component, and wherein A component comprises following material: modified epoxy resin 45kg, polyvinyl alcohol 0.1 kg, sorbitan monooleate 2kg, fatty acid glycerides 2kg, tricresyl phosphate 5kg, triethanolamine 10kg, xylene 30kg and bentonite 1kg;

[0035] The B component includes the following materials: polyurethane prepolymer 25kg, didecyl phthalate 10kg, dewatering agent 5kg, titanium dioxide 5kg, silane coupling agent A-187 0.5kg and stannous octoate 0.1kg;

[0036] Described modified epoxy resin obtains according to the following steps:

[0037] ①Put 50kg of bisphenol A and 100kg of epichlorohydrin in the reactor, mix them evenly, raise the temperature of the system to 50°C, then add 20kg of 30% sodium hydroxide aqueous solution to the reactor dropwise, and the reaction time is 2 hours. After the reaction was complete...

Embodiment 2

[0042] A kind of anti-rust and anti-corrosion fitness equipment primer, including A component and B component, wherein A component includes the following materials: modified epoxy resin 55kg, polyvinyl alcohol 0.5kg, sorbitan monooleate 6kg , fatty acid glyceride 5kg, tricresyl phosphate 10kg, triethanolamine 15kg, xylene 40kg and bentonite 2kg;

[0043] The B component includes the following materials: 40kg of polyurethane prepolymer, 25kg of didecyl phthalate, 10kg of dewatering agent, 10kg of titanium dioxide, 1kg of silane coupling agent A-187 and 1kg of stannous octoate;

[0044] Described modified epoxy resin obtains according to the following steps:

[0045] ①Put 55kg of bisphenol A and 125kg of epichlorohydrin in the reactor, mix well, raise the temperature of the system to 60°C, then add 30kg of 40% sodium hydroxide aqueous solution to the reactor dropwise, and the reaction time is 3h , after the completion of the reaction, add 60kg water and 30kg toluene therein, le...

Embodiment 3

[0050] A kind of anti-rust and anti-corrosion fitness equipment primer, including A component and B component, wherein A component includes the following materials: modified epoxy resin 48kg, polyvinyl alcohol 0.2kg, sorbitan monooleate 3kg , fatty acid glyceride 4kg, tricresyl phosphate 6kg, triethanolamine 12kg, xylene 32kg and bentonite 1.2kg;

[0051] The B component includes the following materials: polyurethane prepolymer 28kg, didecyl phthalate 16kg, dewatering agent 6kg, titanium dioxide 8kg, silane coupling agent A-187 0.6kg and stannous octoate 0.2kg;

[0052] Described modified epoxy resin obtains according to the following steps:

[0053] ①Put 51kg of bisphenol A and 110kg of epichlorohydrin in the reactor, mix well, raise the temperature of the system to 52°C, then add 23kg of 32% sodium hydroxide aqueous solution to the reactor dropwise, and the reaction time is 2.5 h, after the reaction was completed, add 54kg water and 27kg toluene therein, leave standstill an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com