Oil-immersed type transformer cooling method and its system

An oil-immersed transformer and cooling system technology, which is applied in the direction of transformer/inductor cooling, etc., can solve the problems of small capacity and high transformer manufacturing requirements, and achieve the effects of long life, leakage avoidance and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

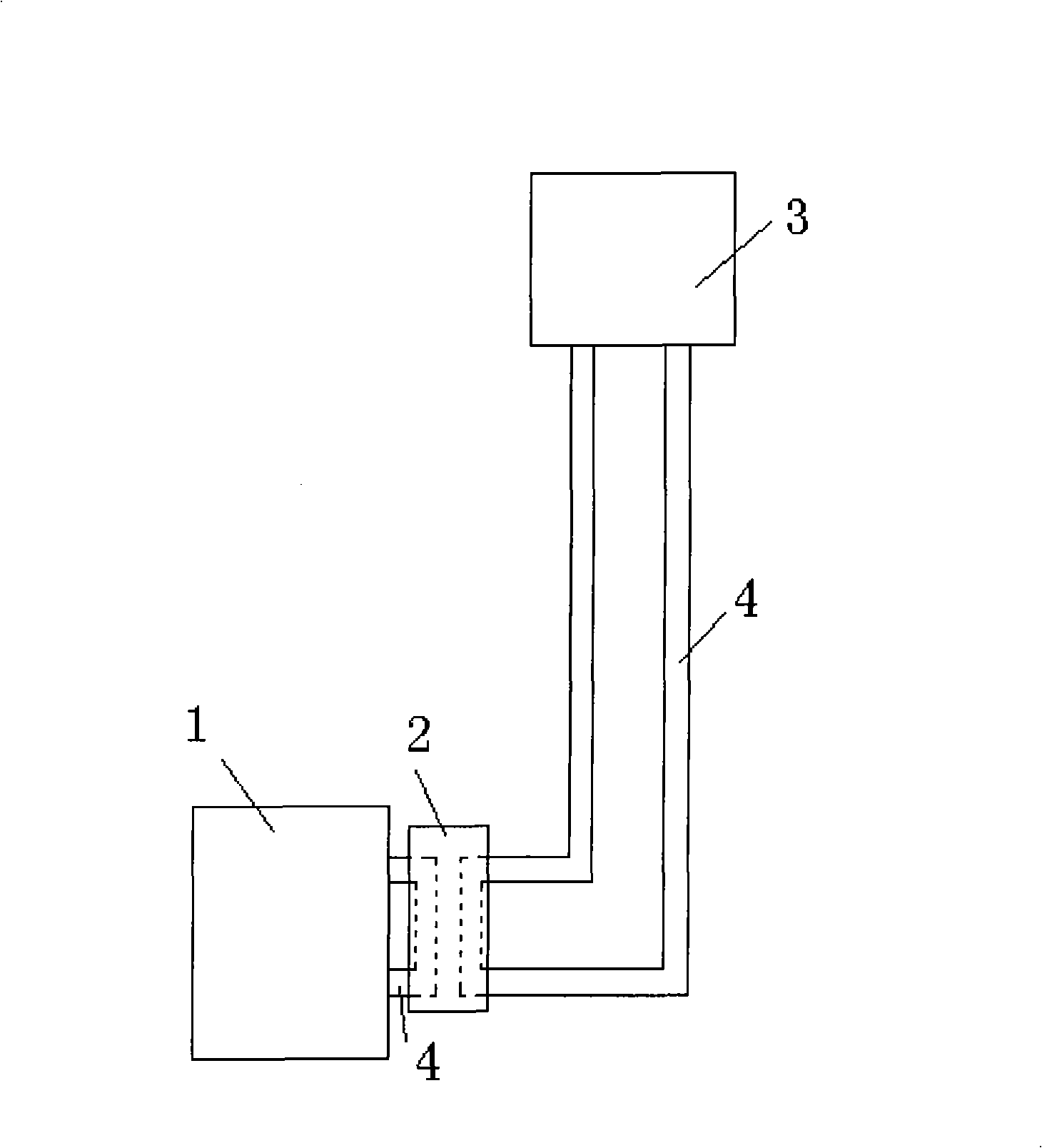

[0032] Embodiment 1: Oil-immersed transformer cooling system. This embodiment has figure 1 structure shown.

[0033] An oil-immersed transformer cooling system, comprising an oil-immersed transformer 1, a heat exchanger 2, and a condensing device 3, composed of a pipeline 4 connecting the oil-immersed transformer 1, the heat exchanger 2, and the condensing device 3; Type transformer 1 and heat exchanger 2 are connected through pipeline 4, and heat exchanger 2 and the condensing device 3 are connected through pipeline 4; Transformer oil is filled in oil-immersed transformer 1, and is filled with heat exchange through pipeline 4 The liquid evaporative cooling medium is stored in the evaporative cooling medium part of the heat exchanger 2, and the transformer oil transfers heat to the lower temperature liquid evaporative cooling medium through the heat exchanger 2. After the temperature of the liquid evaporative cooling medium rises Vaporization, the gaseous evaporative cooling...

Embodiment 2

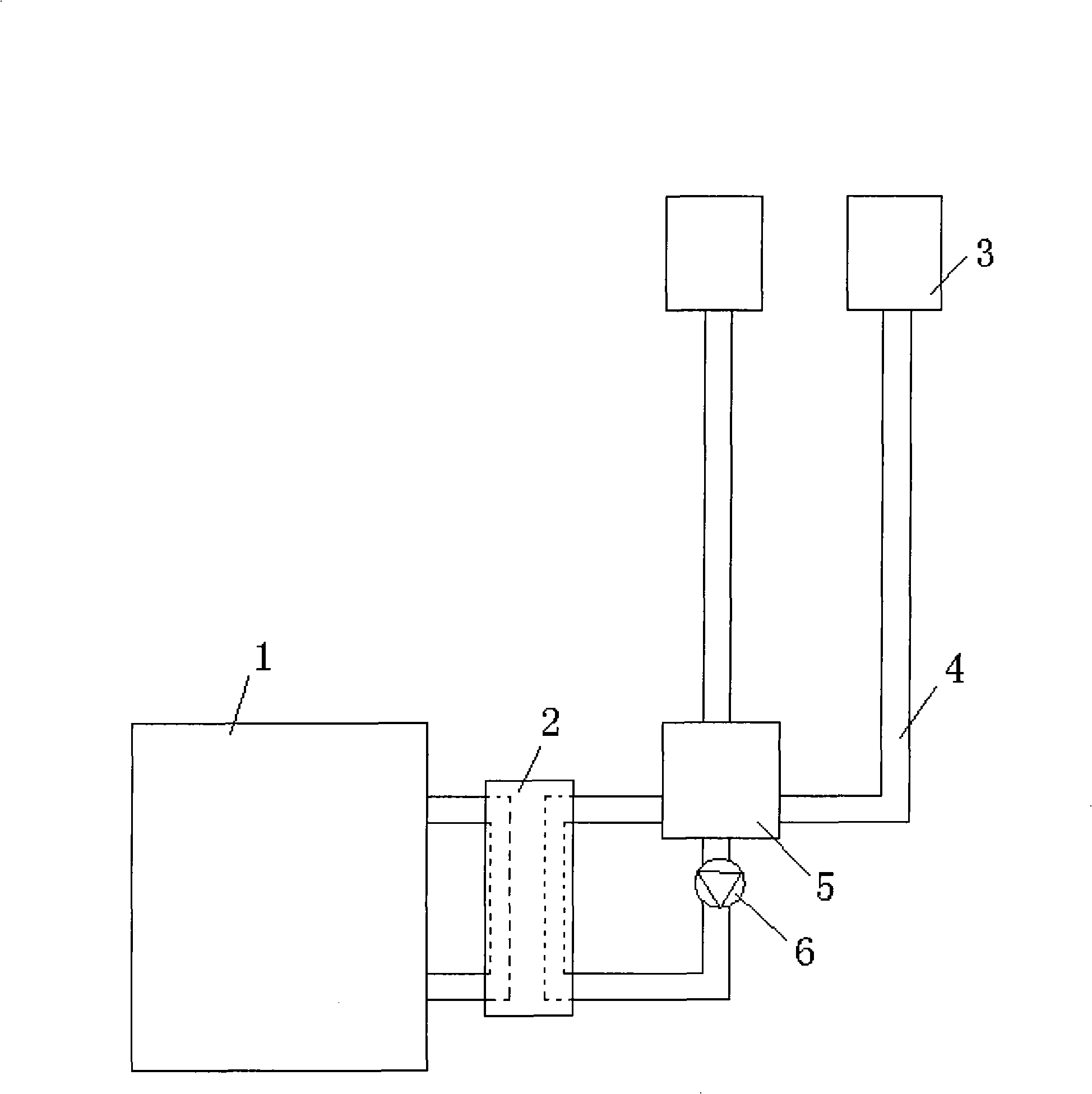

[0036] Embodiment 2: Oil-immersed transformer cooling system. This embodiment has figure 2 structure shown.

[0037]A cooling system for an oil-immersed transformer includes an oil-immersed transformer 1 , a heat exchanger 2 , a condensing device 3 , a liquid evaporative cooling medium tank 5 , a circulation pump 6 and a connecting pipeline 4 . The oil-immersed transformer 1 and the oil circuit part of the heat exchanger 2 are connected through a pipeline 4, and the evaporative medium part of the heat exchanger 2 is connected with the liquid evaporative cooling medium tank 5 through a circulating pump 6, and the liquid evaporates The cooling medium box 5 and the condensing device 3 are connected through pipelines; the transformer oil is filled in the oil-immersed transformer 1, and the oil circuit part of the heat exchanger 2 is filled through the pipeline 4, and the liquid evaporative cooling medium is stored in the liquid evaporative Cooling medium box 5 , the gaseous eva...

example 2

[0038] The working principle of Example 2 is similar to that of Example 1, except that the circulation pump 6 accelerates the self-circulation of the evaporating liquid medium.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com