Rare earth aluminum alloy conductor and preparation method thereof

An aluminum alloy wire, aluminum alloy technology, applied in metal/alloy conductors, cable/conductor manufacturing, electrical components, etc., can solve the problems of insufficient continuous development, easy overload and heat generation, and potential safety hazards, saving time and raw material costs. , Reduce the operation steps, the effect of easy removal of impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7

[0107] Melting: According to the formula in Table 1, first melt aluminum and aluminum-iron alloy at 720-730°C, then heat up to 780-790°C and add zinc, antimony, tin, copper, strontium and tellurium in the form of master alloy; fully mix Finally, add light rare earth in the form of master alloy at 760-770°C; after fully mixing, add medium rare earth in the form of master alloy at 730-740°C; after fully mixing, add in the form of master alloy at 780-790°C Heavy rare earth; when the master alloy is added, it should be fed in different positions of the aluminum liquid as much as possible, so that the composition of the master alloy can be more quickly and evenly dispersed in the aluminum liquid; after being fully mixed, it is refined at 760-770°C refining agent, the components of the refining agent are: sodium nitrate 60wt%, graphite powder 10wt%, cryolite 30wt% (each component meets: sodium nitrate 50-70wt%, graphite powder 5-15wt%, cryolite 20wt% -40wt% can be used). The weight...

Embodiment 8

[0119] Prepare the rare earth aluminum alloy stranded conductor, the steps are as follows:

[0120] a) Stranding: using the aluminum alloy wire obtained in Example 3, twisting through a concentric layer stranding process;

[0121] b) annealing: performing annealing treatment on the aluminum alloy stranded wire obtained in step a;

[0122] The annealing method is a three-stage annealing, and the three-stage annealing specifically refers to placing the aluminum alloy twisted coil obtained in step 1 in an annealing furnace, and the annealing furnace is divided into upper, lower, Middle and lower temperature zones, the heating temperature range of the upper temperature zone is 340-360°C, the temperature range of the middle temperature zone is 350-370°C, and the temperature range of the lower temperature zone is 360-370°C, The annealing time is 4-10h.

[0123] The obtained stranded conductor fill factor is ≥92%. Visually observe the cross-section of the stranded conductor, the s...

Embodiment 9

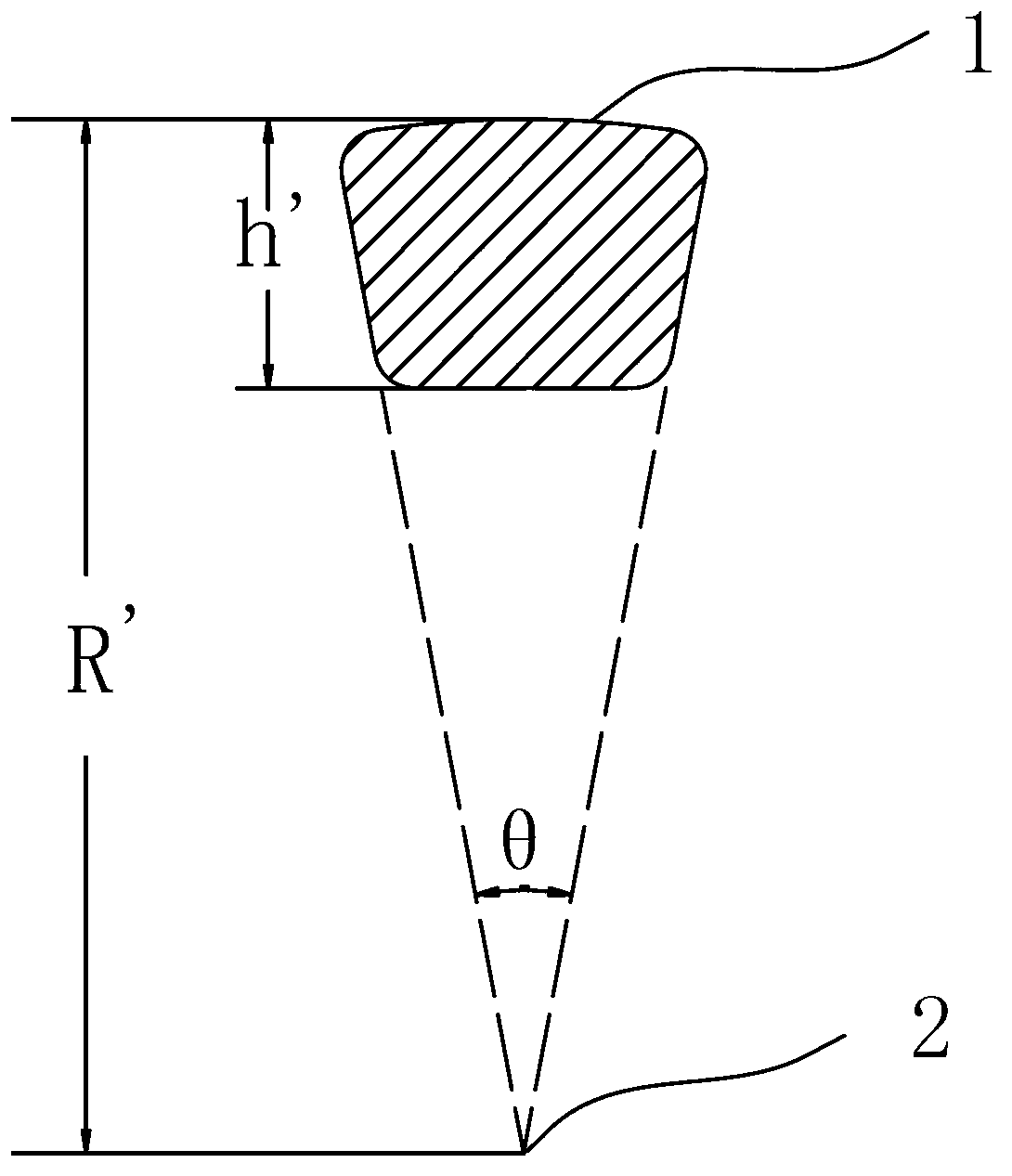

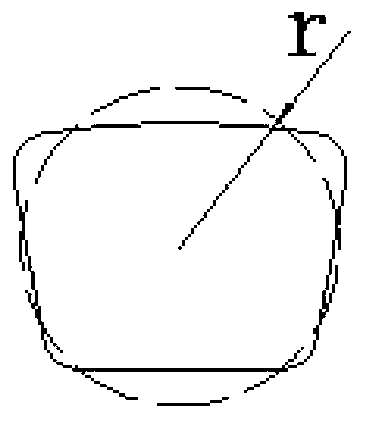

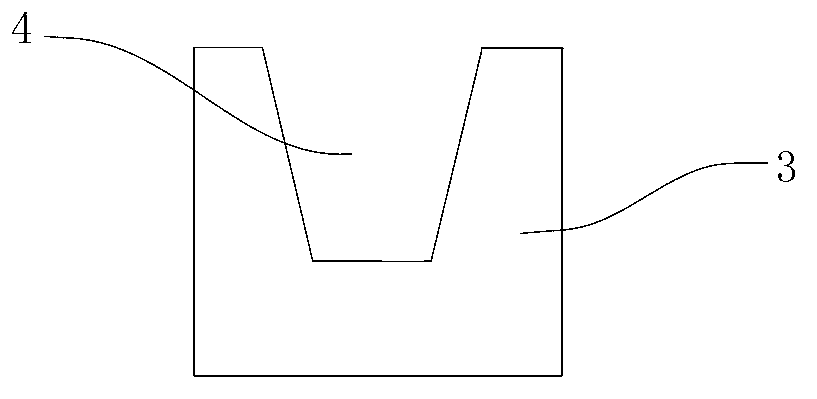

[0125] The formula in Example 3 was used to prepare round monofilament wires respectively, and the round monofilament wires were extruded into special-shaped aluminum alloy monofilament wires through crimping holes. The cross-section of the special-shaped aluminum alloy monofilament wire is as follows figure 1 Shown is a special-shaped isosceles trapezoid, the long base of the special-shaped isosceles trapezoid is an arc 1, and the center of the circle coincides with the intersection point 2 of the extension line of the waist line of the special-shaped isosceles trapezoid. The four corners of the special-shaped isosceles trapezoid are all rounded.

[0126] In the special-shaped aluminum alloy stranded conductor, the number n of special-shaped aluminum alloy monofilament wires used in each layer is:

[0127]

[0128] The θ simultaneously satisfies the formula:

[0129] 57 h R ≤ θ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Outer radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com