High-strength fireproof crucible and production method thereof

A high-strength, crucible technology, applied in the field of refractory materials, can solve the problems of reduced strength, high cost, and low porosity of refractory crucibles, and achieve the effects of preventing crucible cracking, improving density and reducing usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

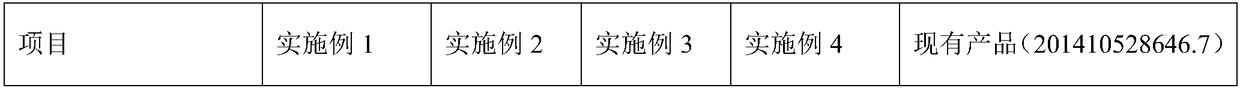

Examples

Embodiment 1

[0036] A high-strength refractory crucible is made of mud material and additives.

[0037] Among them, the mud material includes the following raw materials in parts by weight: 60 parts of magnesium ore, 10 parts of zirconia, 10 parts of fused magnesia, 10 parts of waste graphite powder, 5 parts of metal magnesium powder, 5 parts of chromium oxide powder, resorcinol 0.4 parts of diglycidyl ether, 0.2 parts of sodium dodecylbenzenesulfonate, 25 parts of ethanol, and 15 parts of water.

[0038] The additives include the following raw materials in parts by weight: 0.08 parts of cationic photocuring initiator (iodonium tetrakis(perfluorophenyl)borate), 0.12 parts of tetradecyltrimethylammonium bromide, 5 parts of ethanol, and 5 parts of water.

[0039] The particle size of the magnesium ore is less than 5mm, the particle size of the zirconia is less than 1mm, the particle size of the fused magnesia is less than 0.088mm, the particle size of the waste graphite powder is less than 0...

Embodiment 2

[0048] A high-strength refractory crucible is made of mud material and additives.

[0049] Among them, the mud material includes the following raw materials in parts by weight: 55 parts of magnesium ore, 15 parts of zirconia, 15 parts of fused magnesia, 10 parts of waste graphite powder, 3 parts of metal magnesium powder, 1 part of chromium oxide powder, resorcinol 0.3 part of diglycidyl ether, 0.1 part of sodium dodecylbenzenesulfonate, 20 parts of ethanol, 10 parts of water;

[0050] The additives include the following raw materials in parts by weight: 0.05 part of cationic photocuring initiator (iodonium tetrakis(perfluorophenyl)borate), 0.05 part of tetradecyltrimethylammonium bromide, 3 parts of ethanol, and 3 parts of water.

[0051] The particle size of the magnesium ore is less than 5mm, the particle size of the zirconia is less than 1mm, the particle size of the fused magnesia is less than 0.088mm, the particle size of the waste graphite powder is less than 0.088mm, a...

Embodiment 3

[0060] A high-strength refractory crucible is made of mud material and additives.

[0061] Among them, the mud material includes the following raw materials in parts by weight: 65 parts of magnesium ore, 5 parts of zirconia, 5 parts of fused magnesia, 15 parts of waste graphite powder, 3 parts of metal magnesium powder, 5 parts of chromium oxide powder, resorcinol 0.5 part of diglycidyl ether, 0.3 part of sodium dodecylbenzenesulfonate, 30 parts of ethanol, 20 parts of water;

[0062] The additives include the following raw materials in parts by weight: 0.1 part of cationic photocuring initiator (iodonium tetrakis(perfluorophenyl)borate), 0.2 part of tetradecyltrimethylammonium bromide, 7 parts of ethanol, and 7 parts of water.

[0063] The particle size of the magnesium ore is less than 5mm, the particle size of the zirconia is less than 1mm, the particle size of the fused magnesia is less than 0.088mm, the particle size of the waste graphite powder is less than 0.088mm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com