an organic light emitting diode

A light-emitting diode, an organic technology, applied in the direction of organic semiconductor devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of low luminous efficiency of organic light-emitting diodes, achieve the effect of short life and improve luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

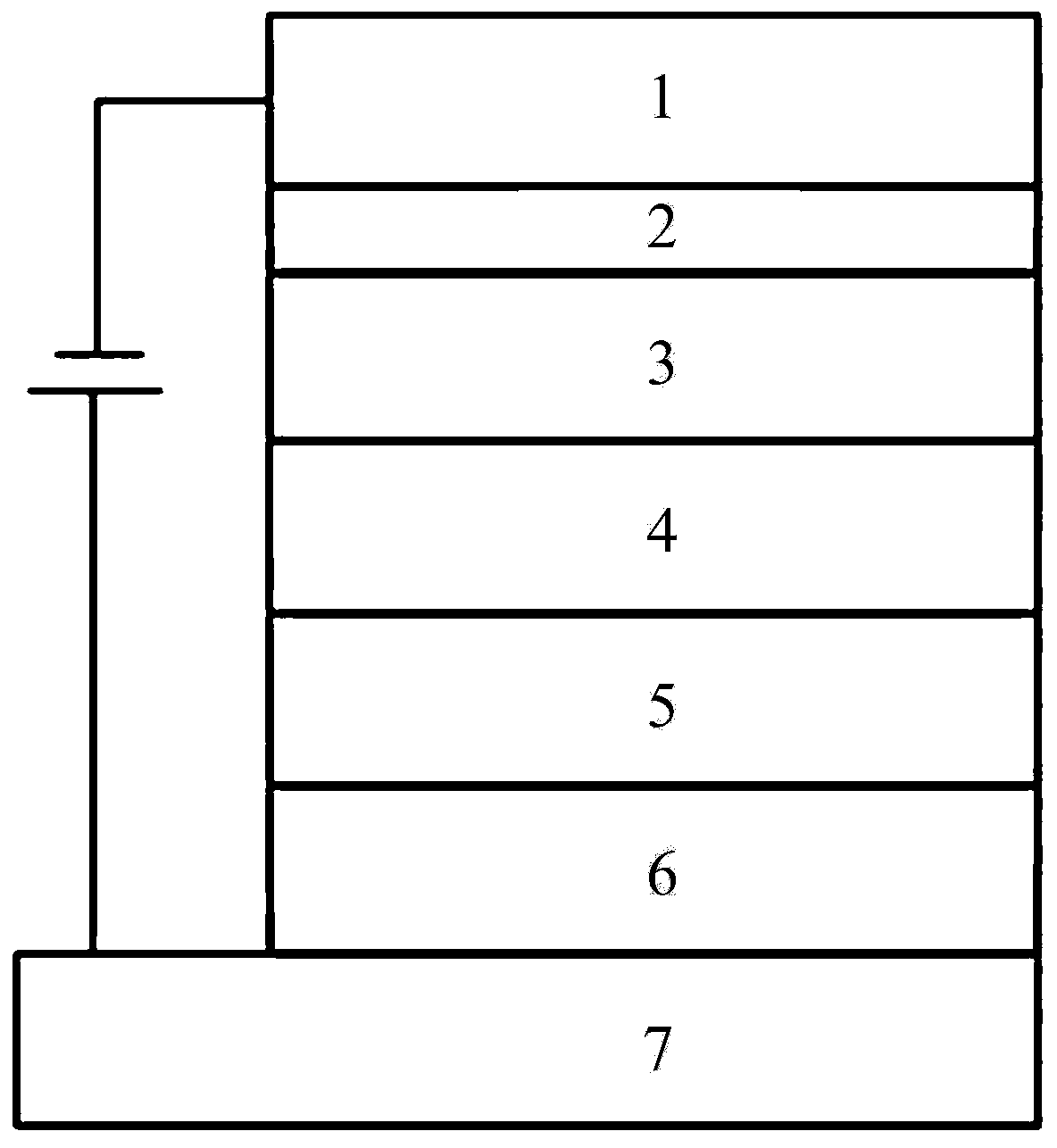

[0049] The present invention also provides a method for preparing the organic light-emitting diode, comprising sequentially depositing a hole injection layer 6, a hole transport layer 5, a light-emitting layer 4, an electron transport layer 3, an electron injection layer 2 and a cathode 1 stacked on an ITO substrate. , and then encapsulate.

[0050]The substrate can be glass or a flexible substrate, and the flexible substrate can be made of polyester, polyimide compound material or thin metal sheet. The lamination and packaging can adopt any suitable method known to those skilled in the art.

Embodiment 1

[0076] In this comparative example, ITO (indium tin oxide) is used as the anode; NPB is used as the hole injection layer; TCTA is used as the hole transport layer; The mass percentage of doping in is 3wt%); Bphen is used as the electron transport layer; Li(5nm) / Al is used as the cathode. The structure is as follows:

[0077] ITO / NPB(40nm) / TCTA(10nm) / CBP: 1wt%;

[0078] Ir(bt)2(acac)(30nm) / Bphen(40nm) / LiF(5nm) / Al.

Embodiment 2

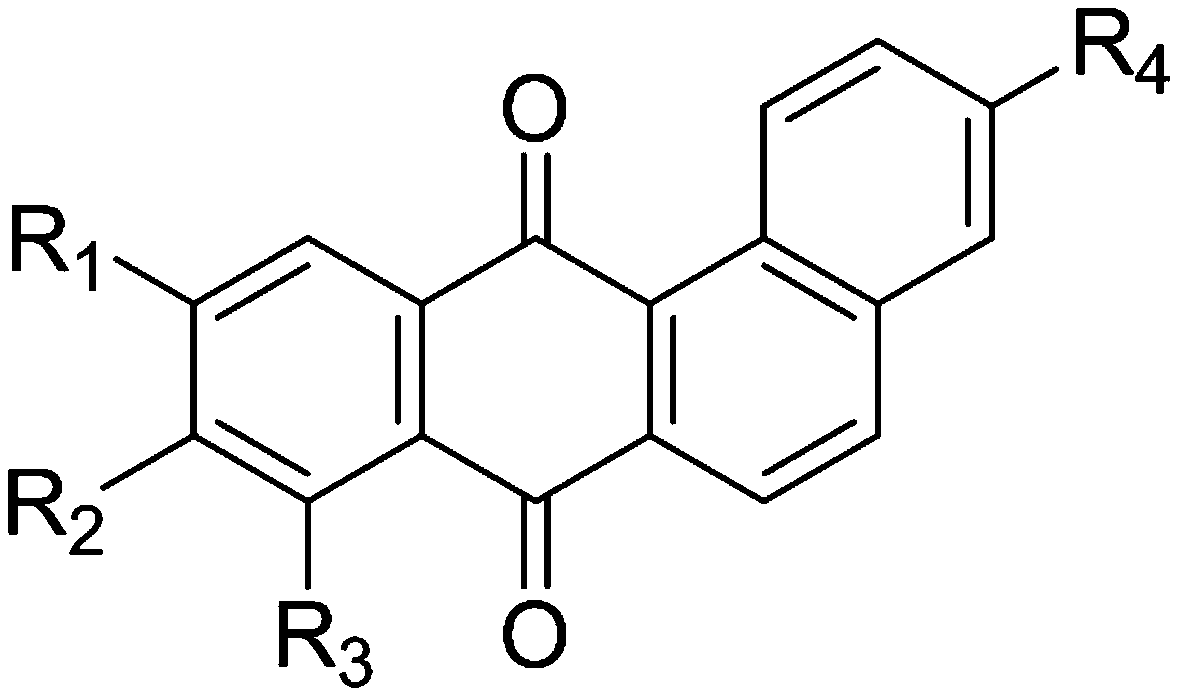

[0080] The structure of this example is the same as that of Comparative Example 1 except that the host material used in the light-emitting layer 4 is the compound of formula (2-6) of the present invention. The structure is as follows:

[0081] ITO / NPB(40nm) / TCTA(10nm) / Formula (1-9): 1 wt% Ir(bt)2(acac)(30nm) / Bphen(40nm) / LiF(5nm) / Al.

[0082] Table 2

[0083]

[0084] The red phosphorescent organic electroluminescent device of the present invention uses a new heat-activated sensitized fluorescent material as the main body sensitized phosphorescent material device, and the current of the heat-activated sensitized fluorescent material sensitized phosphorescent material device is higher than that of the common main body sensitized phosphorescent material and the reported thermally activated sensitized fluorescent material sensitized phosphorescent material device. The efficiency is high, and the voltage is the lowest, indicating that the ΔEST of the heat-activated sensitized f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com