Acid-resistant high-mechanical-strength magnetic acrylic-series weak acid cation exchange microspherical resin and method of preparing same

A weak acid cation, mechanical strength technology, applied in the field of resin materials, can solve the problems of low mechanical strength, poor acid corrosion resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

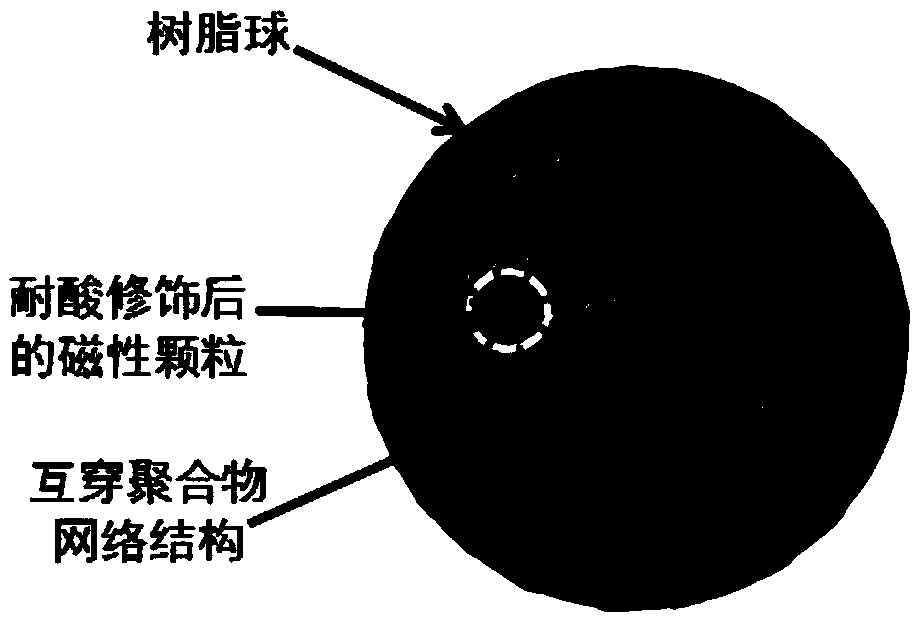

[0070] Weigh 20g of Fe with a particle size of about 8nm to 300nm 3 o 4 Add it into 500mL methanol solution, stir for 30min, add 1g of silane coupling agent tetraethoxysilane, adjust the pH to 10-11, raise the temperature to 50°C, stir thoroughly for 30min, then add 1g of dimethyldiethoxysilane , adjust the pH to 10-11, fully stir at 50°C for 1 hour, filter to obtain magnetic powder particles with a silicon oxide layer-hydrophobic layer, and dry at 40°C until there is no moisture on the surface.

[0071]With the magnetic powder particles after this treatment and 80g methyl acrylate, 12.7g divinylbenzene, 7.3g ethylene glycol dimethacrylate, 0.6g azobisisobutyronitrile, 1.2g benzoyl peroxide, 30g cyclohexane Alcohol, 0.5g isopropyl dioleic acid acyloxy (dioctylphosphoryloxy) titanate mixed, fully stirred at 40 ℃ for 45 minutes, added to 500mL containing 0.5% hydroxyethyl cellulose, 5% Suspension polymerization was carried out in a 1L three-necked flask, and the stirring speed...

Embodiment 2

[0075] Weigh 20g of Fe with a particle size of about 8nm to 300nm 3 o 4 Add it into 500mL methanol solution, stir for 30min, add 1g of silane coupling agent tetraethoxysilane, adjust the pH to 10-11, raise the temperature to 50°C, stir thoroughly for 30min, then add 1g of dimethyldiethoxysilane , adjust the pH to 10-11, stir thoroughly at 50°C for 1 hour, add 1g of silane coupling agent tetraethoxysilane again, adjust the pH to 10-11, raise the temperature to 50°C, stir thoroughly for 30min, then add 1g of dimethyl Diethoxysilane, pH adjusted to 10-11, fully stirred at 50°C for 1 hour to obtain magnetic powder particles with silicon oxide layer-hydrophobic layer-silicon oxide layer-hydrophobic layer, and dried at 40°C until the surface has no moisture.

[0076] With the magnetic powder particles after this treatment and 80g methyl acrylate, 12.7g divinylbenzene, 7.3g ethylene glycol dimethacrylate, 0.6g azobisisobutyronitrile, 1.2g benzoyl peroxide, 30g cyclohexane Alcohol, ...

Embodiment 3

[0080] Weigh 30g of α-Fe with particle size less than 1μm 2 o 3 , γ-Fe 2 o 3 Add the mixture into 500mL of methanol solution, stir for 30min, add 2g of silane coupling agent tetramethoxysilane, adjust the pH to 10-11, raise the temperature to 50°C, stir thoroughly for 30min, then add 1g of n-propyltriethoxy Silane, adjust the pH to 10-11, stir thoroughly at 50°C for 1 hour, add 1g of silane coupling agent tetramethoxysilane again, adjust the pH to 10-11, raise the temperature to 50°C, stir thoroughly for 30min, then add 1g of methyl Trimethoxysilane, pH adjusted to 10-11, fully stirred at 50°C for 1 hour to obtain magnetic powder particles with silicon oxide layer-hydrophobic layer-silicon oxide layer-hydrophobic layer, and dried at 40°C until there is no moisture on the surface.

[0081] With the magnetic powder particles after this treatment and 80g methyl acrylate, 12.7g divinylbenzene, 7.3g ethylene glycol dimethacrylate, 0.6g azobisisobutyronitrile, 1.2g benzoyl peroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

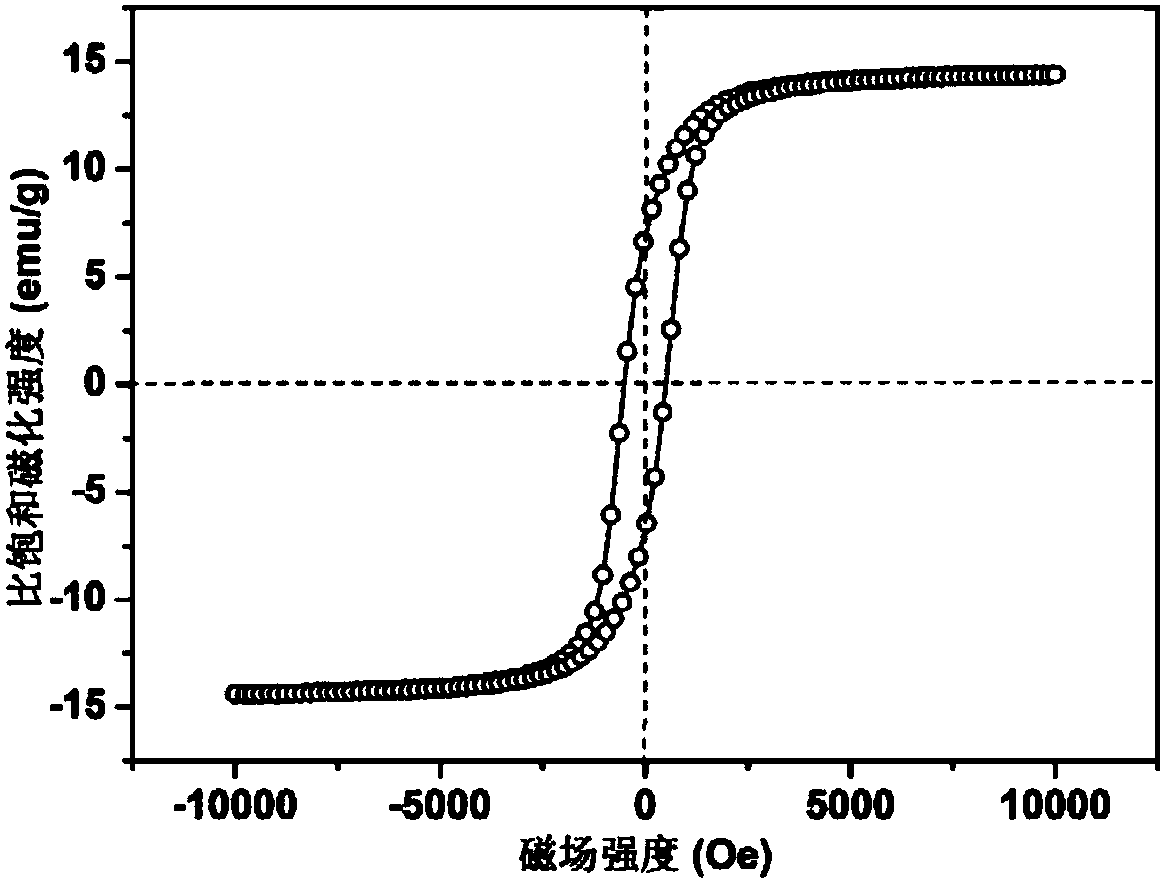

| Specific saturation magnetization | aaaaa | aaaaa |

| Specific saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com