Preparation method for CQDs/GCNNs/Fe(2-x)TixO3/FTO photo-anode

A fe2-xtixo3, photoanode technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of high overpotential, high energy consumption of photoelectric splitting water for hydrogen production, high activation energy, improve efficiency and solve the problem of reaction kinetics , the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

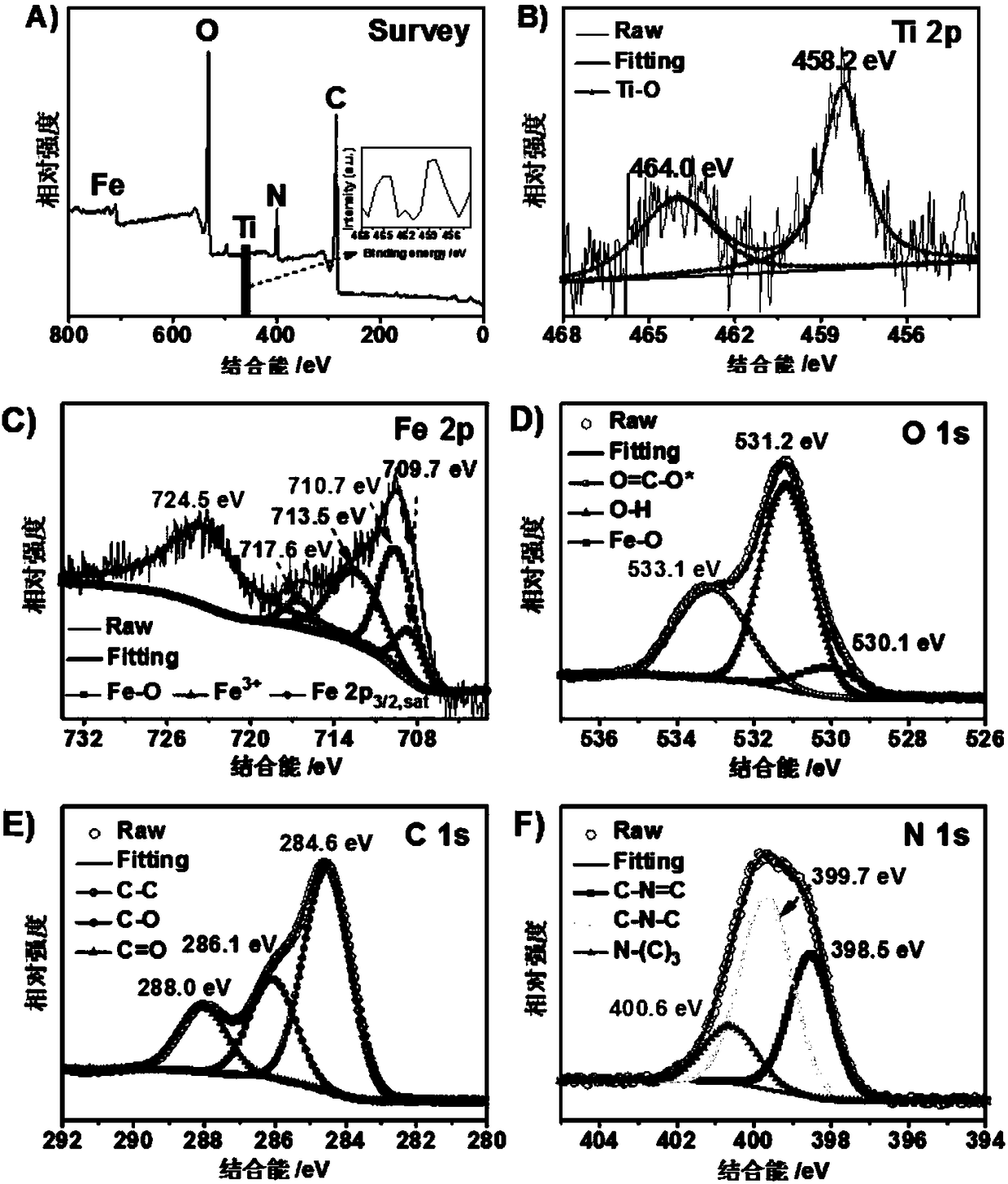

Image

Examples

Embodiment 1

[0029] (1) prepare 0.1 mole of ferric chloride (purity ≥ 99.0%) aqueous solution and 0.15 mole of urea (purity ≥ 99.5%) aqueous solution;

[0030] (2) Take 0.2 milliliters of titanium tetrachloride (purity ≥ 99.5%) solution, add 20 milliliters of absolute ethanol (ethanol content ≥ 99.5%) to it, stir and mix evenly;

[0031] (3) Take out 180 microliters of solution from step (2), add the solution prepared in step (1), and stir for 30 minutes;

[0032](4) Put the FTO sheet cut to a certain area into water for 20 minutes, then put it into ethanol for 20 minutes, then put it into acetone solvent for 30 minutes, and finally dry it with high-purity nitrogen. FTO film;

[0033] (5) Get 30 milliliters of the solution in the step (3) and add it to a 50 milliliter polytetrafluoroethylene reaction kettle with a stainless steel substrate, then put the FTO sheet cleaned in the step (4) into the above-mentioned reaction kettle , where the conductive surface of the FTO sheet is placed dow...

Embodiment 2

[0037] (1)~(7) are with embodiment 1;

[0038] (8) will pass through the Fe prepared in step (7) 2-x Ti x o 3 / FTO slices were placed in a crucible containing dicyandiamide, 2cm above the dicyandiamide, and then calcined at 530°C for 3 hours in an air atmosphere, and were taken out after cooling down to room temperature to obtain GCNNs / Fe 2-x Ti x o 3 / FTO photoanode; the photocurrent density is 2.75mA / cm at 1.23V voltage (relative to reversible hydrogen electrode) after photoelectrochemical test 2 .

Embodiment 3

[0040] (1)~(7) are with embodiment 1;

[0041] (8) Prepare a 0.08 mole aqueous solution of sucrose, followed by carbonization at 180°C for 5 hours to obtain a CQDs solution (12.5 mg / L);

[0042] (9) The CQDs liquid prepared in step (8) is uniformly coated on the Fe prepared in step (7) by a spin coating process. 2- x Ti x o 3 / FTO, that is, get CQDs / Fe 2-x Ti x o 3 / FTO photoanode; the photocurrent density is 2.49mA / cm at 1.23V voltage (relative to reversible hydrogen electrode) after photoelectrochemical test 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com