TPU floor board and preparation method thereof

A floor and formula technology, applied in chemical instruments and methods, flat products, other household appliances, etc., can solve problems affecting people's health and safety, and achieve the effect of strong industrial application promotion, pollution reduction, and excellent low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

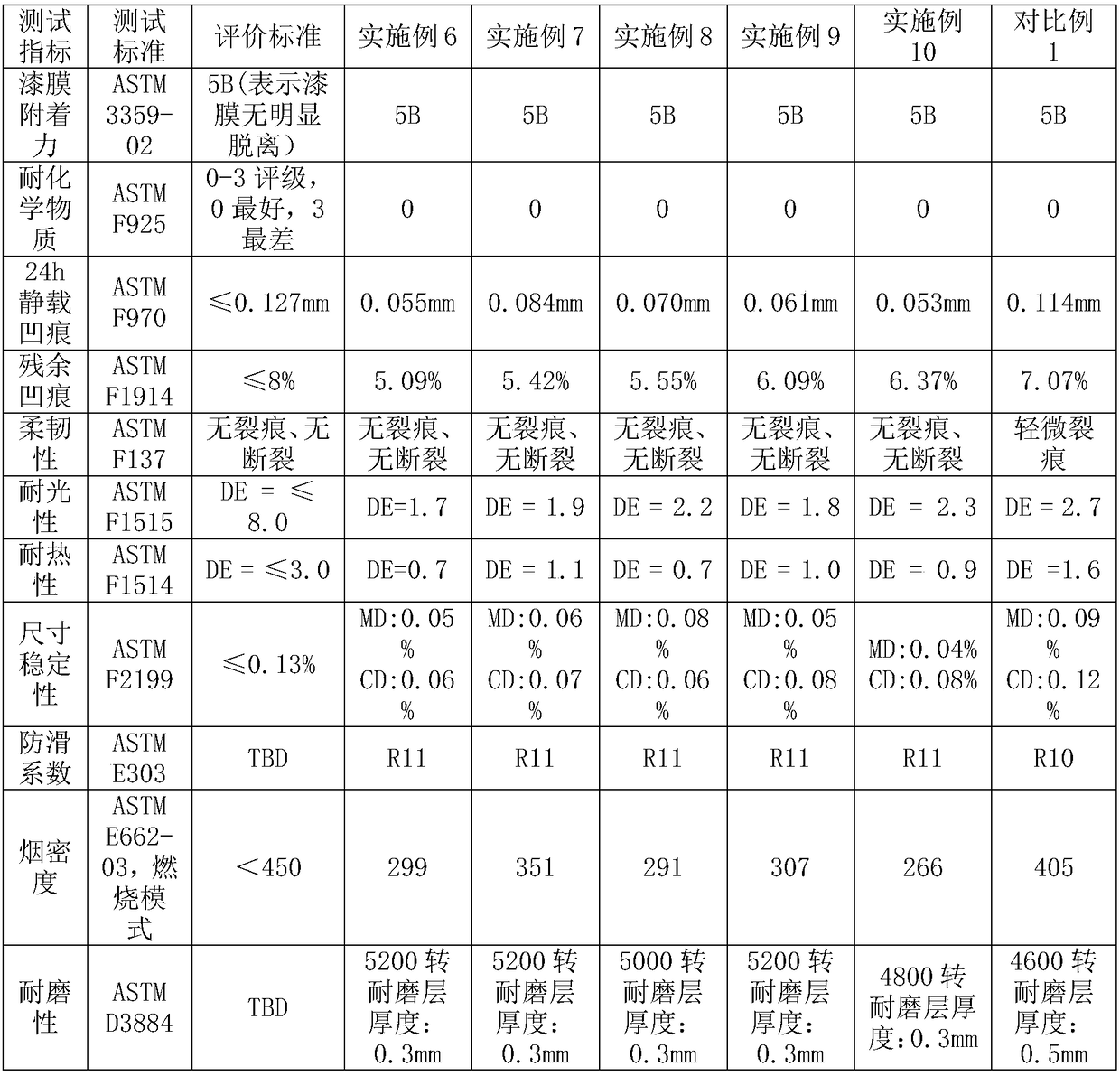

Examples

Embodiment 1

[0031] A TPU floor, which is composed of a laminated structure of TPU wear-resistant layer, TPU color film, TPU surface layer, glass fiber mesh cloth, and TPU film from top to bottom;

[0032] The formula of the TPU surface layer and the TPU back sheet includes the following components in terms of mass: 75 parts of TPU particles, 25 parts of ABS resin, 15 parts of bio-based softener, 3.0 parts of external lubricant, 1.5 parts of internal lubricant, ultraviolet absorber 0.8 parts of anti-oxidant, 0.5 parts of antioxidant, 18 parts of silica reinforcing agent, 250 parts of filler;

[0033] The formula of the TPU wear-resistant layer includes the following components by mass: 80 parts of TPU particles, 1.8 parts of external lubricant, 1.2 parts of internal lubricant, 1.2 parts of ultraviolet absorber, and 0.3 parts of antioxidant.

[0034] In order to obtain the best floor performance and improve the blending effect with other materials, the hardness of the TPU particles is 80A; ...

Embodiment 2

[0037] A TPU floor, which is composed of a laminated structure of TPU wear-resistant layer, TPU color film, TPU surface layer, glass fiber mesh cloth, and TPU film from top to bottom;

[0038] The formula of the TPU surface layer and the TPU back sheet includes the following components by mass: 50 parts of TPU particles, 50 parts of ABS resin, 5 parts of bio-based softener, 1.0 parts of external lubricant, 2.0 parts of internal lubricant, and ultraviolet absorber 0.5 parts, 0.2 parts of antioxidant, 40 parts of silica reinforcing agent, 100 parts of filler;

[0039] The formula of the TPU wear-resistant layer includes the following components by mass: 80 parts of TPU particles, 1.8 parts of external lubricant, 1.2 parts of internal lubricant, 1.2 parts of ultraviolet absorber, and 0.3 parts of antioxidant.

[0040] In order to obtain the best floor performance and improve the blending effect with other materials, the hardness of the TPU particles is 75A; the thickness of the T...

Embodiment 3

[0043] A TPU floor, which is composed of a laminated structure of TPU wear-resistant layer, TPU color film, TPU surface layer, glass fiber mesh cloth, and TPU film from top to bottom;

[0044]The formula of the TPU surface layer and the TPU backsheet includes the following components by mass: 60 parts of TPU particles, 40 parts of ABS resin, 20 parts of bio-based softener, 1.8 parts of external lubricant, 1.0 part of internal lubricant, and ultraviolet absorber 0.8 parts, 0.5 parts of antioxidant, 20 parts of silica reinforcing agent, 230 parts of filler.

[0045] The formula of the TPU wear-resistant layer includes the following components by mass: 80 parts of TPU particles, 1.8 parts of external lubricant, 1.2 parts of internal lubricant, 1.2 parts of ultraviolet absorber, and 0.3 parts of antioxidant.

[0046] In order to obtain the best floor performance and improve the blending effect with other materials, the hardness of the TPU particles is 80A; the thickness of the TPU...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com