Damp-proof rustproof coating solder ring and preparation method thereof

A solder ring and solder technology, applied in manufacturing tools, welding equipment, metal processing equipment, etc., can solve problems such as affecting the appearance and performance of the solder ring, damaging the health of operators, and being difficult to prepare into a ring, etc. Achieve the effect of strong ability to remove oxide film, improve brazing efficiency and reduce moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

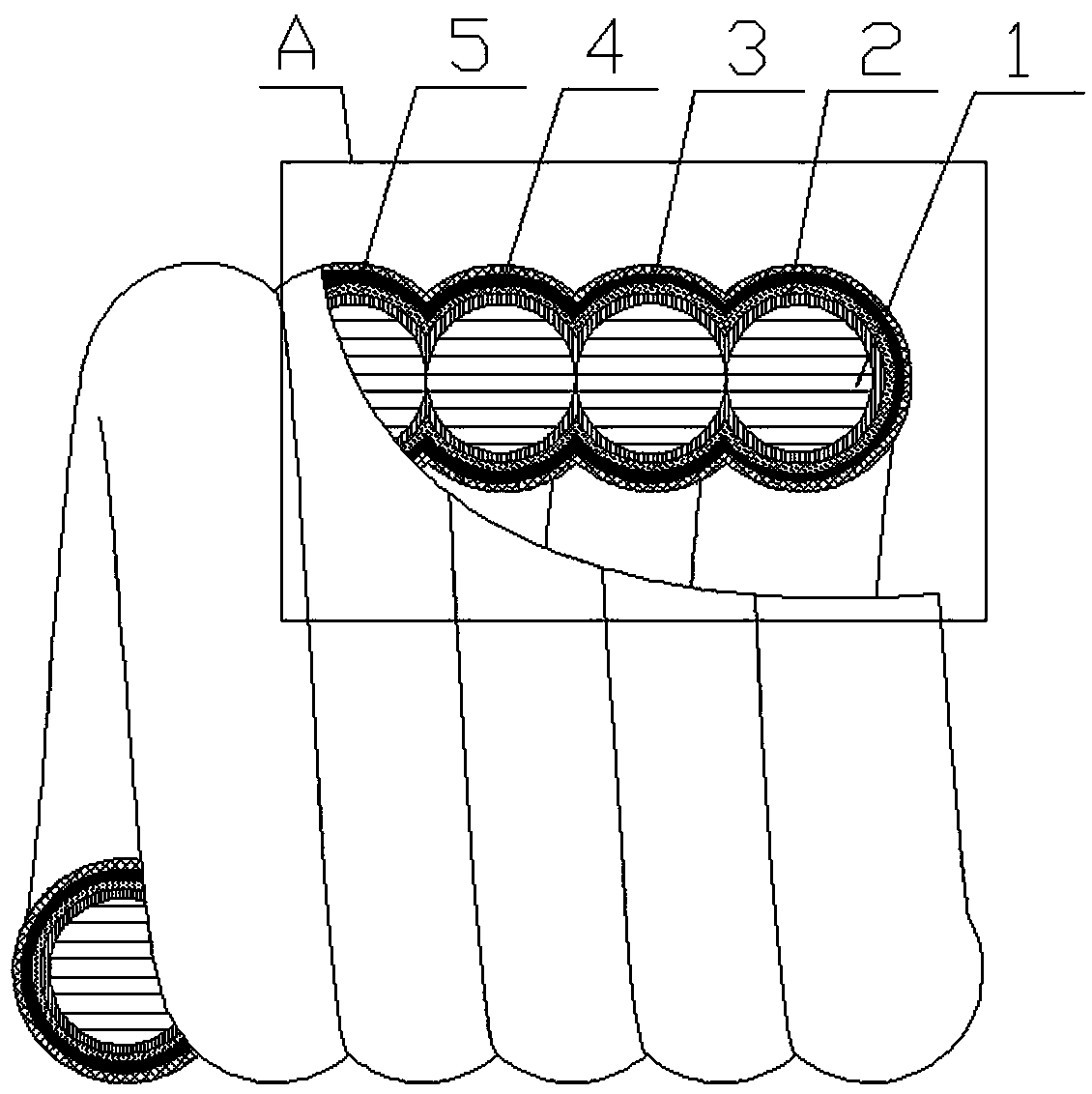

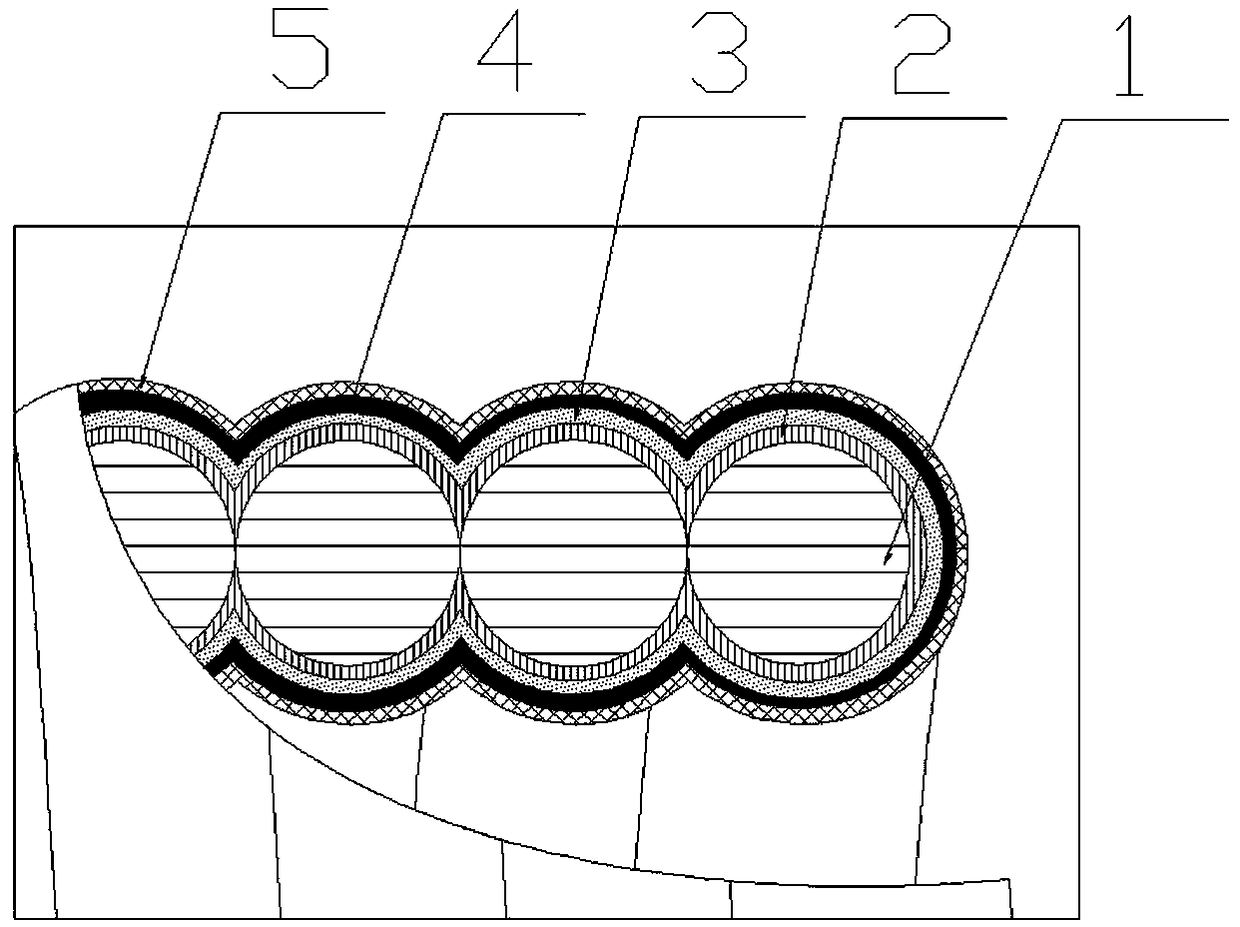

[0027] Such as figure 1 and figure 2 As shown, a moisture-proof and rust-proof sheathed solder ring of the present invention includes a solder inner core 1, a metal coating 2 plated on the outer circumference of the solder inner core 1, and a metal coating 2 coated on the outer circumference of the metal coating 2. The high activity flux layer 3 , the weak moisture absorption flux layer 4 coated on the outer periphery of the high activity flux layer 3 , and the moisture-proof outer layer 5 adhered to the outer periphery of the weak moisture absorption flux layer 4 .

[0028] The brazing material inner core 1 is a spring-shaped brazing material, which is made of thin wire brazing material by winding two or more turns, and the difference between the pitch and the wire diameter of the brazing material inner core 1 is greater than or equal to zero and less than or equal to 1mm. The metal coating 2 is a tin-plated layer or an indium-plated layer, and the highly active flux layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com