Lithium ion battery anode material, lithium ion battery anode piece as well as preparation method thereof and lithium ion battery

A technology for lithium-ion batteries and cathode materials, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the high cost of N-methylpyrrolidone, increase the production cost of lithium-ion batteries, and damage the health of workers and other issues, to achieve the effect of reducing processing costs, eliminating hidden dangers to human health, and reducing preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] According to a third aspect of the present invention, the present invention provides a method for preparing the positive electrode sheet of the above-mentioned lithium ion battery, comprising the steps of:

[0066] (a) adding the positive electrode material of the lithium ion battery into water and dispersing evenly to prepare the positive electrode slurry of the lithium ion battery;

[0067] (b) Coating the positive electrode slurry of the lithium ion battery on the current collector, followed by drying and rolling to obtain the positive electrode sheet of the lithium ion battery.

[0068] The preparation method of the lithium-ion battery positive plate provided by the invention uses cheap and pollution-free water instead of N-methylpyrrolidone as a solvent, which reduces environmental pollution, eliminates hidden dangers to human health, saves energy, and reduces the processing cost of lithium-ion batteries .

[0069] According to the fourth aspect of the present inv...

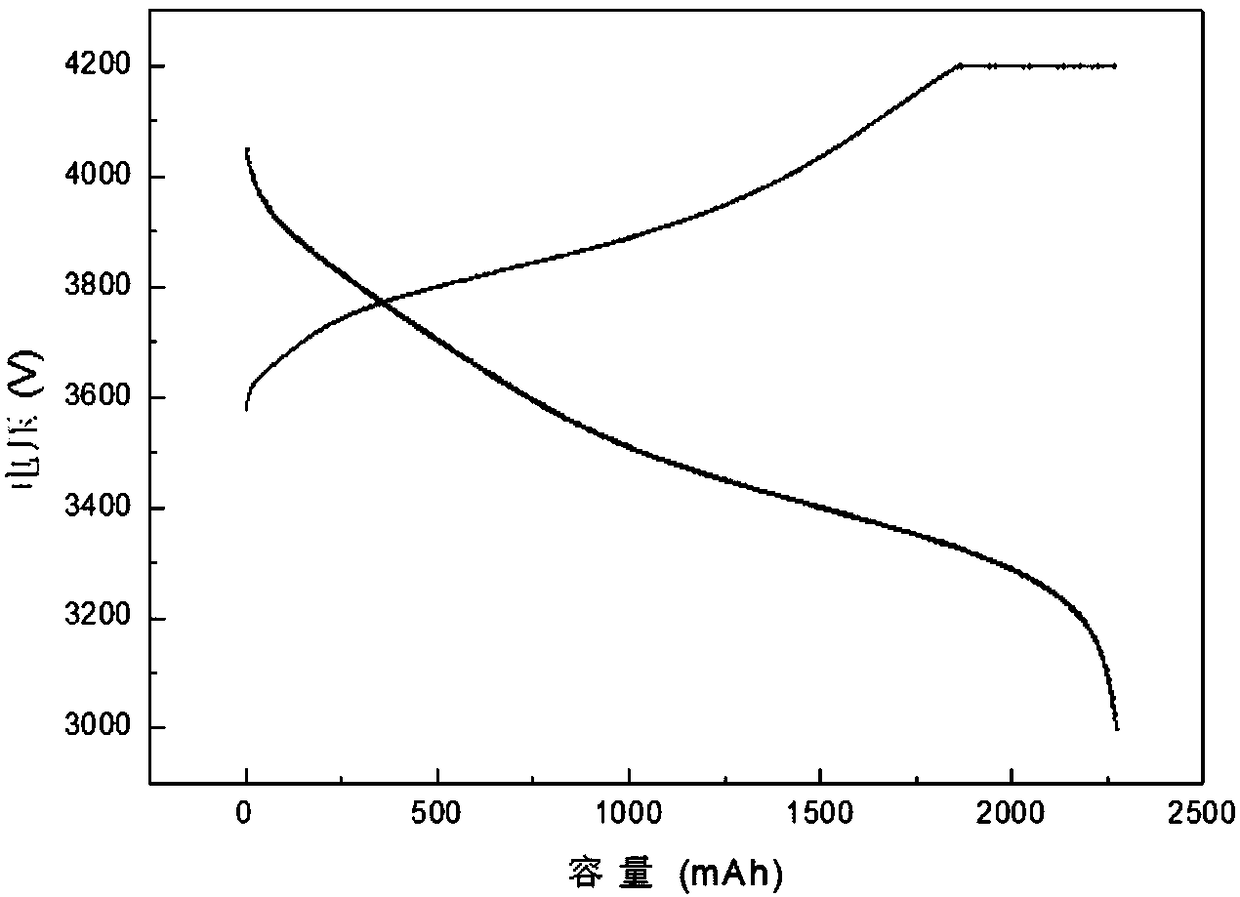

Embodiment 1

[0073] This embodiment provides a lithium-ion battery, including a lithium-ion battery positive electrode sheet and a lithium-ion battery negative electrode sheet, the lithium-ion battery positive electrode sheet is prepared by coating the lithium-ion battery positive electrode sheet on an aluminum foil, and the lithium-ion battery positive electrode material It is prepared from the following raw materials: nickel cobalt lithium manganate: 95.0wt%, polyacrylamide binder: 2.5wt% and acetylene black: 2.5wt%; among them, the polyacrylamide binder is acrylamide-ethylene Alcohol-n-hexyl acrylate block copolymer, the number average molecular weight is 22 million, and the proportion of polymer block of acrylamide monomer unit is 80wt%, the proportion of polymer block of vinyl alcohol monomer unit is 10wt%, acrylic acid The n-butyl monomer unit polymer block accounts for 10 wt%.

[0074] The preparation steps of lithium-ion battery cathode sheet are as follows:

[0075] (a) adding th...

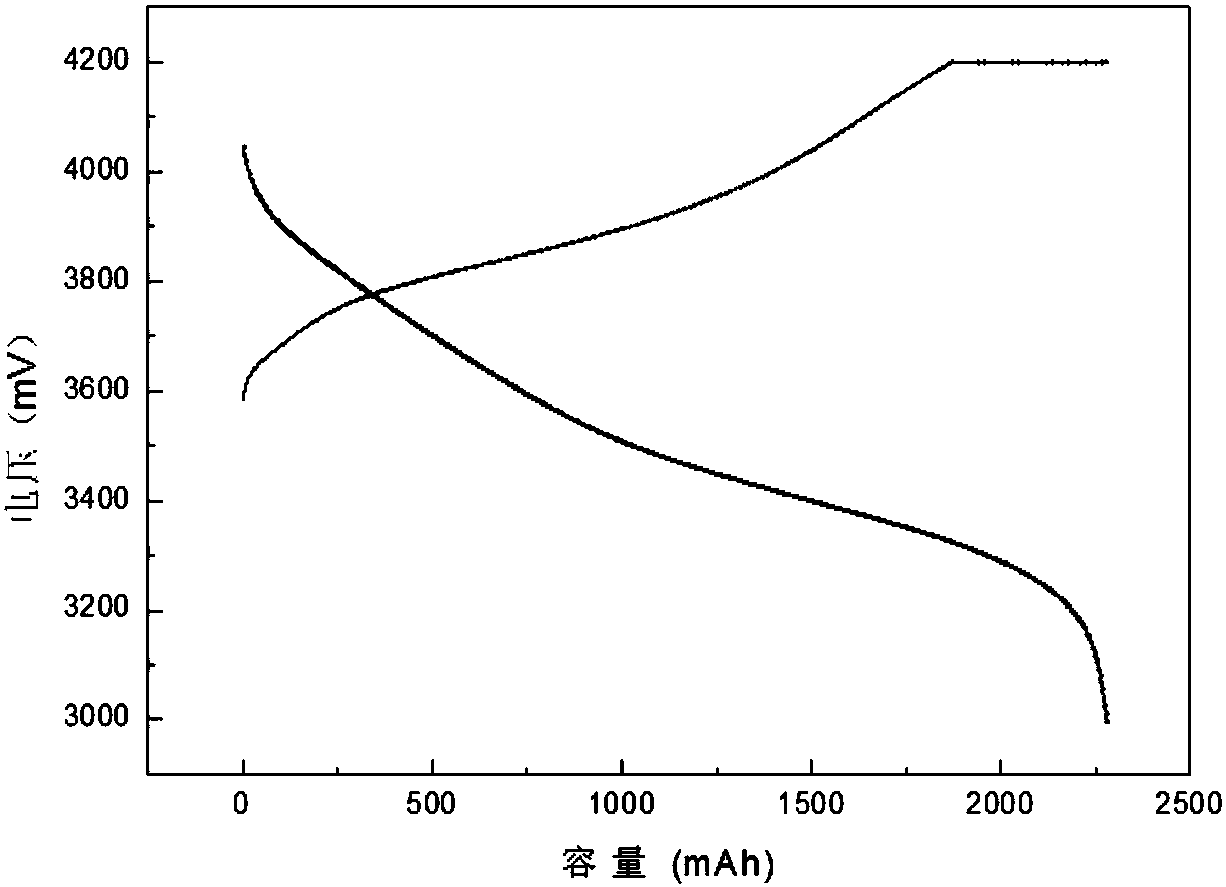

Embodiment 2

[0079] This embodiment provides a lithium-ion battery, including a lithium-ion battery positive electrode sheet and a lithium-ion battery negative electrode sheet, the lithium-ion battery positive electrode sheet is prepared by coating a lithium-ion battery positive electrode material on a copper foil, and its lithium-ion battery positive electrode The material is prepared from the following raw materials: nickel cobalt lithium manganate: 70wt%, lithium manganate: 26wt%, polyacrylamide adhesive: 0.6wt%, LA132: 0.9wt%, acetylene black: 1.5wt%, conductive Graphite (KS6): 1wt%; Among them, the polyacrylamide binder is acrylamide-vinyl alcohol-n-butyl acrylate block copolymer, the number average molecular weight is 1 million, and the polymer block of acrylamide monomer unit The proportion of vinyl alcohol monomer unit polymer block is 50wt%, the proportion of vinyl alcohol monomer unit polymer block is 20wt%, and the proportion of n-butyl acrylate monomer unit polymer block is 30wt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com