Sulfonium salt bonded phenol type molecular glass photoresist, preparation method and application thereof

A technology of photoresist and positive photoresist, which is applied in the field of photolithography and can solve problems such as pattern collapse, crossover, and lower resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

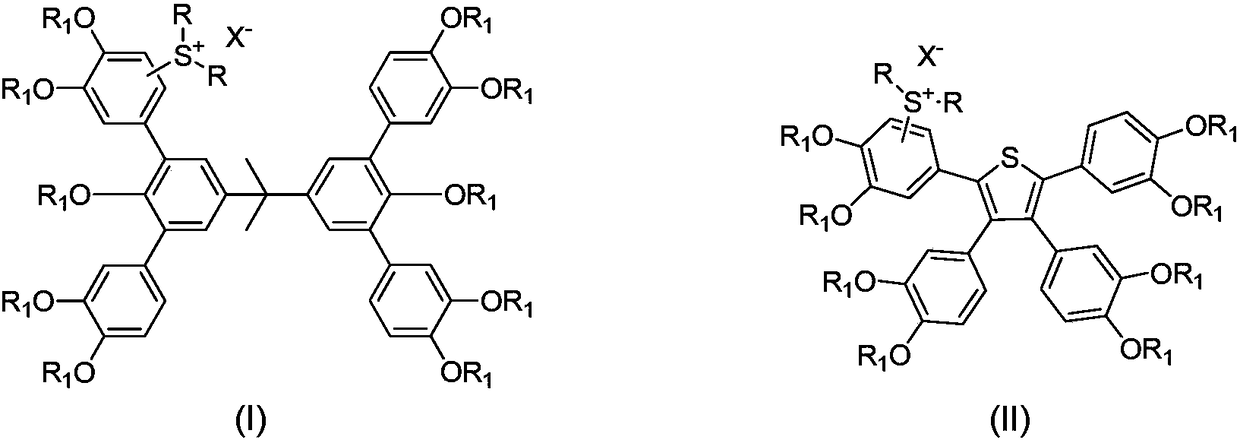

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

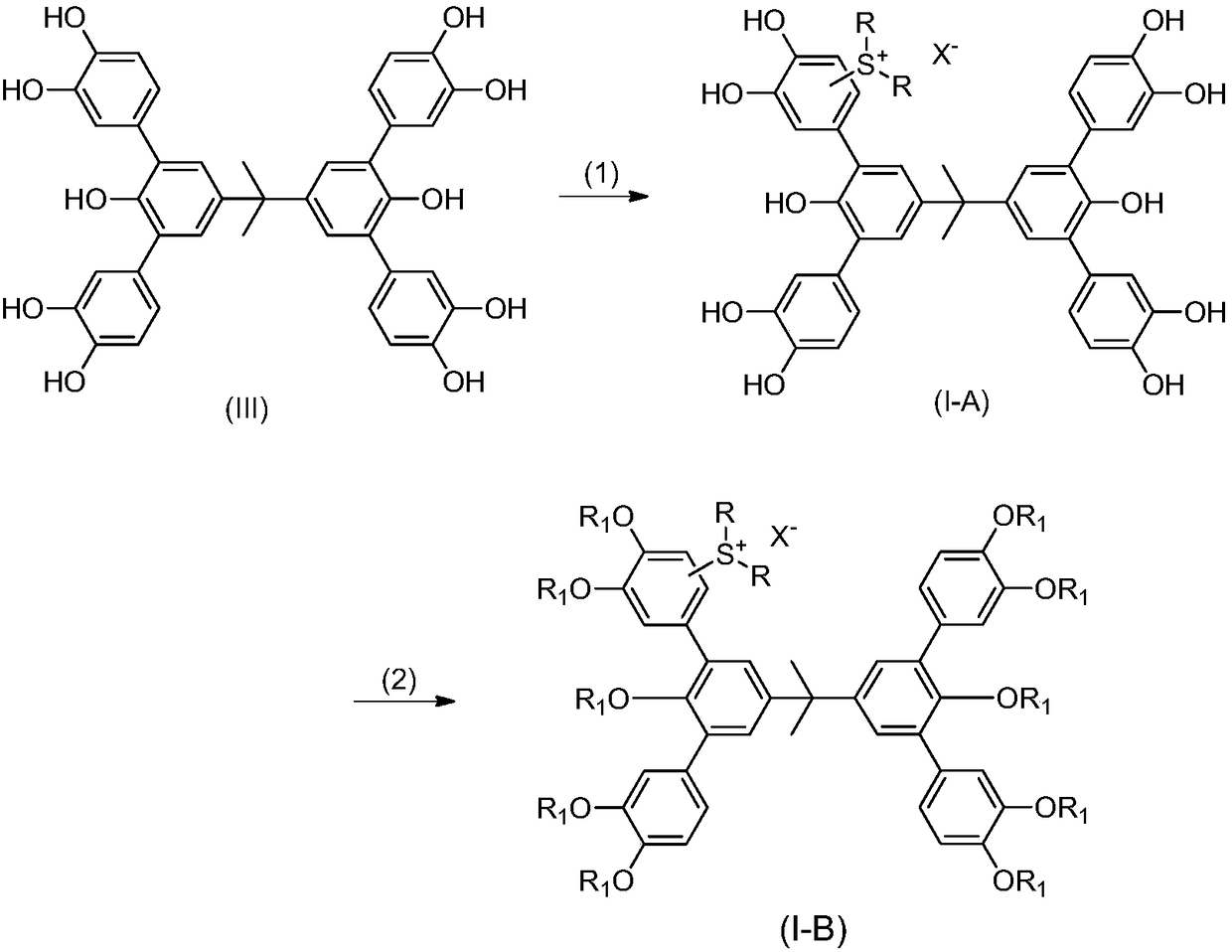

[0060]1. Preparation of dimethyl-2,2-bis(4-hydroxy-3,5-bis(3,4-dihydroxyphenyl)phenyl)propylsulfonium chloride (1-B)

[0061]

[0062] Dissolve 3.3g of 2,2-bis(4-hydroxy-3,5-bis(3,4-dihydroxyphenyl)phenyl)propane(III) (5mmol) in 30mL of methanol solvent and add it to a 100mL three-necked flask , under the condition of ice-water bath, hydrogen chloride gas was fed continuously, 0.39 g dimethyl sulfoxide (5 mmol) dissolved in 10 mL methanol was added dropwise, and the mixture was kept at 0° C. and stirred for 2-3 hours. After the reaction was complete, spin the solution to dryness, add water and ethyl acetate for extraction, retain the aqueous phase, collect the aqueous phase after multiple extractions, spin dry, and dry in a vacuum oven at 50°C overnight to obtain a light yellow solid powder.

[0063] MALDI-TOF (C 41 h 37 ClO 10 S), m / z: 721.2.

[0064] 2. Preparation of dimethyl-2,2-bis(4-hydroxy-3,5-bis(3,4-dihydroxyphenyl)phenyl)propylsulfonium salt of perfluorobutane...

Embodiment 2

[0073] 1. Preparation of dimethyl-2,3,4,5-tetrakis(3,4-dihydroxyphenyl)thiophenesulfonium chloride (2-B)

[0074]

[0075] Dissolve 2.6g of 2,3,4,5-tetrakis(3,4-dihydroxyphenyl)thiophene (IV) (5mmol) in 30mL of methanol solvent, add it to a 100mL three-necked flask, and continuously feed Hydrogen chloride gas, 0.39 g of dimethyl sulfoxide (5 mmol) dissolved in 10 mL of methanol was added dropwise, and the mixture was kept at 0° C. and stirred for 2-3 hours. After the reaction was complete, spin the solution to dryness, add water and ethyl acetate for extraction, retain the aqueous phase, collect the aqueous phase after multiple extractions, spin dry, and dry in a vacuum oven at 50°C overnight to obtain a light yellow solid powder.

[0076] MALDI-TOF (C 30 h 25 ClO 8 S 2 ), m / z:577.4.

[0077] 2. Preparation of dimethyl-2,3,4,5-tetrakis(3,4-dihydroxyphenyl)thiophenesulfonium salt of perfluorobutanesulfonate (2-C)

[0078]

[0079] 3.1g dimethyl-2,3,4,5-tetrakis(3,4-...

Embodiment 3

[0088] The preparation of positive photoresist: the compound (1) that 40mg embodiment 1 is prepared is dissolved in 1mL PGMEA and is made into positive photoresist, spin-coats on the silicon chip after hydrophilic and hydrophobic treatment (spin-coating condition is : 500~1000rpm, 0~30s; 1000~2000rpm, 0~30s; 2000~3000rpm, 0~30s).

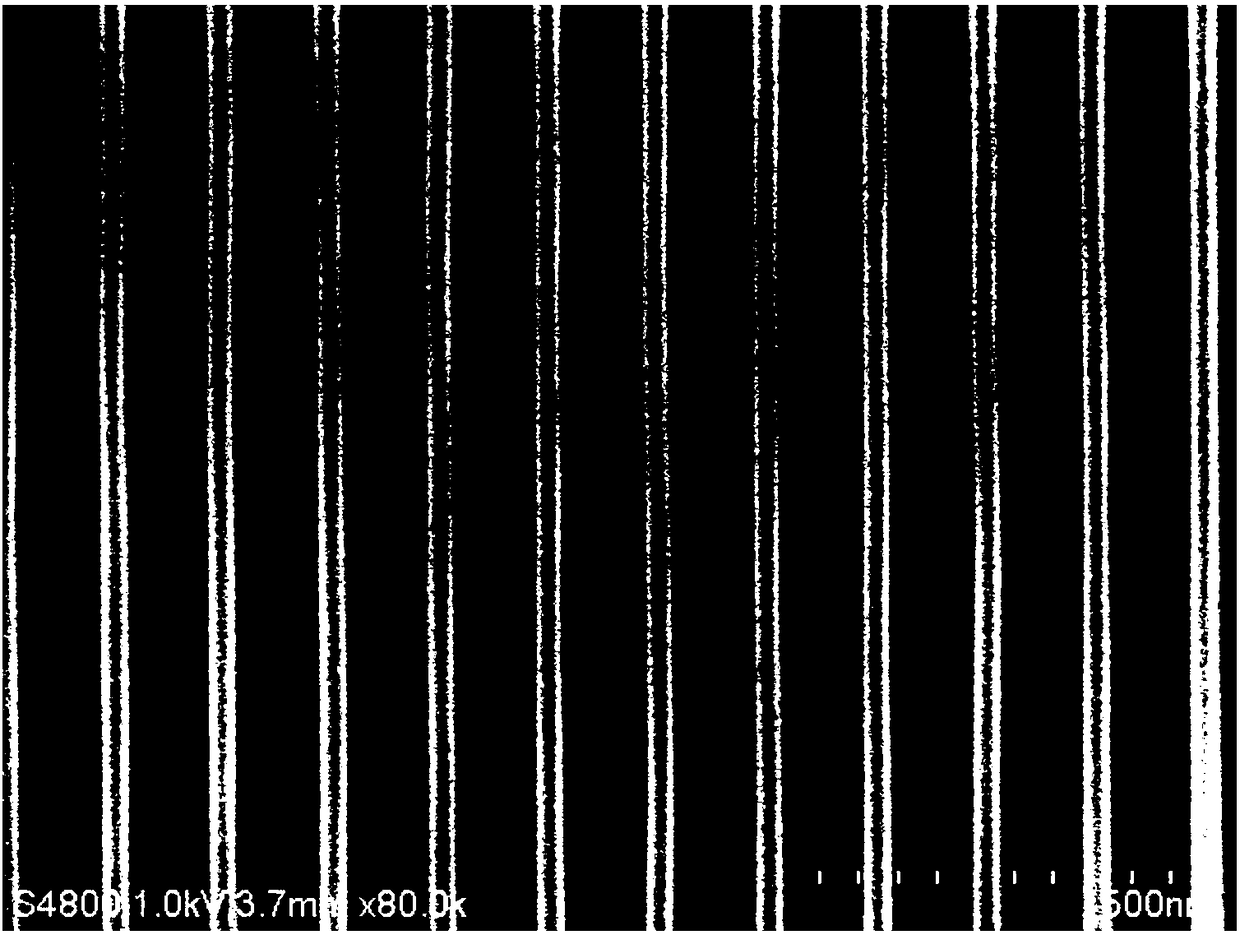

[0089] figure 1 It is a lithography result diagram of EUV lithography performed at the Shanghai Synchrotron Radiation Light Source 08U1B extreme ultraviolet lithography line station using the film prepared in Example 3.

[0090] The results show that the thickness of the film obtained by spin coating is 30-100nm, the film-forming performance is good, the thickness of the obtained film is uniform, and the photolithography pattern with a line width of 70nm to 30nm can be obtained uniformly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com