Biomass microwave pyrolysis oriented gasification method and system

A biomass and microwave technology, applied in the direction of chemical instruments and methods, gasification process, physical/chemical process catalysts, etc., can solve the problems of water vapor consumption, increased energy consumption and gas consumption, and low process economy, so as to solve coking Carbon deposition, strong microwave absorption properties, and the effect of eliminating coking carbon deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Mix bio-semi-coke, bio-tar, nickel oxide, potassium hydroxide and water according to the mass ratio of 15:1:2:2:9. Extrusion temperature is 120°C and extrusion speed is 0.15mm / s. The length is 20mm, the extrusion diameter is 2mm, extruded into strips, the size is φ2mm×4mm, and it is dried at 105°C for 4 hours, and roasted at 500°C for 1 hour in a high-temperature flue gas atmosphere.

Embodiment 2

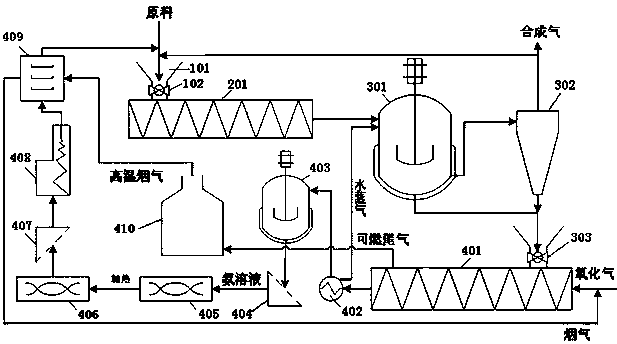

[0067] The biomass microwave pyrolysis directional gasification system of the present invention: as figure 1 As shown, including feed components, microwave pyrolysis components, microwave gasification components and catalyst regeneration components, where:

[0068] The feed assembly includes a feed bin 101 and an unloader I 102 for mixing biomass and catalysts and feeding them to the microwave pyrolysis assembly;

[0069] The microwave pyrolysis component includes a microwave pyrolysis reactor 201, and the microwave pyrolysis reactor 201 is used to receive the raw material from the feed component and pyrolyze it into gaseous volatile components and a small amount of biological semi-coke, gas-solid products Both enter the microwave vaporization assembly.

[0070] The microwave gasification assembly includes a microwave gasification reactor 301 and a gas-solid separator 302. The microwave gasification reactor 201 is provided with a gas outlet connected to the gas-solid separato...

Embodiment 3

[0074] Utilize the catalyst of embodiment 1 and the system of embodiment 2 to carry out the process of biomass pyrolysis directional gasification:

[0075] The biomass raw material and catalyst preheated at 120°C are mixed according to the mass ratio of 1:1, then sent to the feeding bin 101, and then enter the microwave pyrolysis reactor 201 through the unloader 102, and are mixed evenly under the action of its ribbon And heat treatment, when the material system reaches 600 ° C, start to adjust the feed rate 1kg / h and carry out microwave pyrolysis reaction at the same time, the reaction time is 2 minutes, and the microwave power density is 10×10 5 W / m 3 After pyrolysis treatment, the conversion of biomass raw materials consists of pyrolysis volatile component products and a small amount of semi-coke, of which pyrolysis volatile components account for 95%, semi-coke accounts for 5%, and pyrolysis volatile components include about 10%. condensing components. Pyrolysis volatile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com