Inorganic photoresist composition patterning method

A photoresist and composition technology, applied in the field of microelectronics, can solve problems such as lack of light sensitivity and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A method for patterning an inorganic photoresist composition, comprising the steps of:

[0052] A) Add an appropriate amount of inorganic photoresist HSQ dropwise on the glass substrate, and spin-coat at 500 rpm for 5 seconds and 4000 rpm for 60 seconds to obtain a photoresist film.

[0053] B) Bake the obtained photoresist film on a hot plate at 50° C. for 10 minutes, then raise the temperature to 100° C. and bake for 3 minutes to obtain a transparent photoresist film.

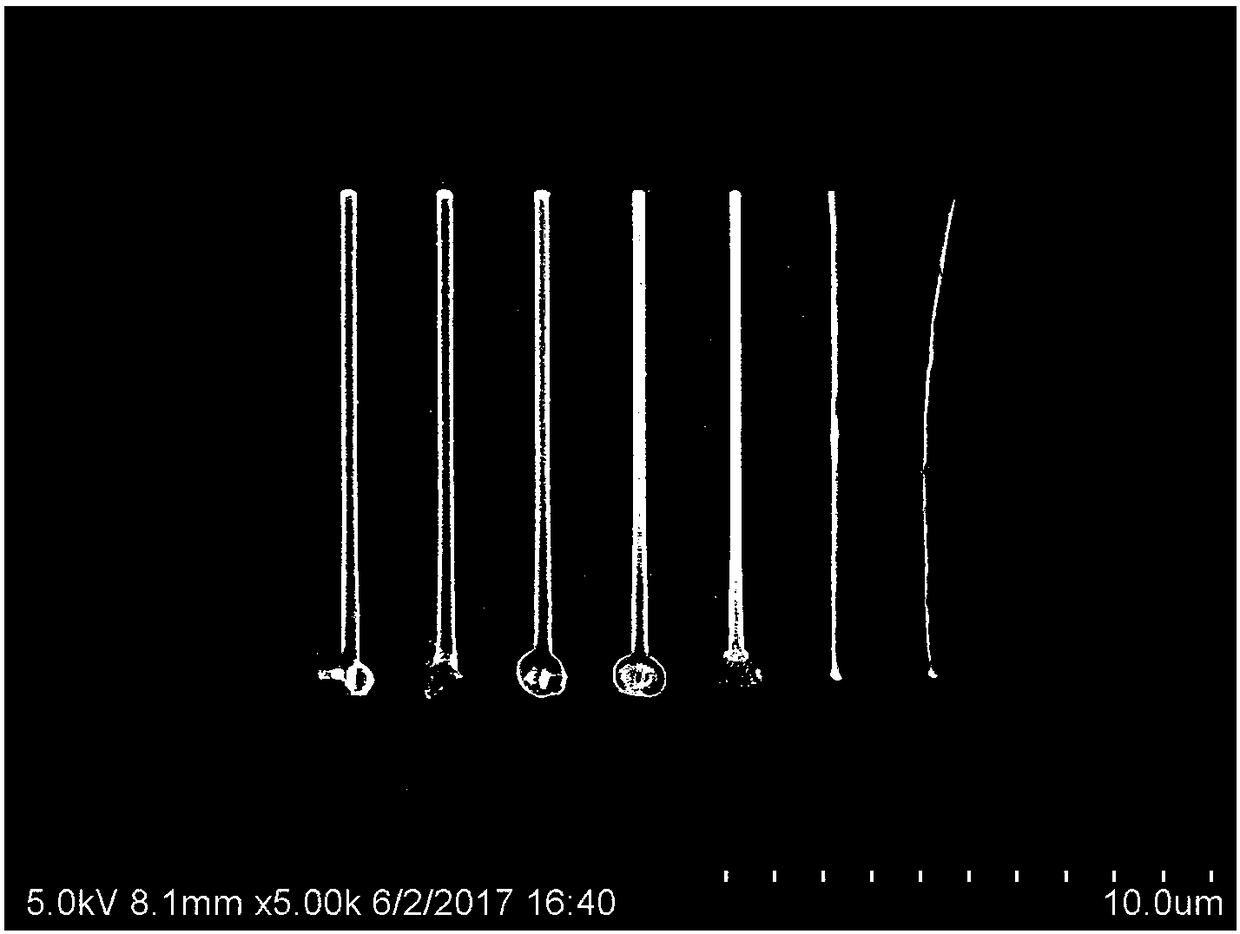

[0054] C) Utilize 780nm femtosecond laser to carry out laser direct writing exposure to this photoresist film, the line structure formed is as follows figure 1 As shown, the photoresist film after exposure was developed for 60 seconds using 0.26mol / L tetramethylammonium hydroxide (TMAH) aqueous solution, washed with deionized water and dried to obtain a photoresist pattern, from figure 1 It can be seen from the photoresist pattern shown that the photoresist pattern of the present invention has a thinn...

Embodiment 2

[0056] A method for patterning an inorganic photoresist composition, comprising the steps of:

[0057] A) Add an appropriate amount of inorganic photoresist HSQ dropwise on the silicon substrate, and spin coat at 500 rpm for 5 seconds and 4000 rpm for 60 seconds to obtain a photoresist film.

[0058] B) Bake the obtained photoresist film on a hot plate at 50° C. for 10 minutes, then raise the temperature to 100° C. and bake for 3 minutes to obtain a transparent photoresist film.

[0059] C) Utilize 780nm femtosecond laser to carry out laser direct writing exposure to this photoresist film, the line structure formed is as follows figure 2 As shown, the photoresist film after exposure was developed for 60 seconds using 0.26mol / L tetramethylammonium hydroxide (TMAH) aqueous solution, washed with deionized water and dried to obtain a photoresist pattern, from figure 2 From the photoresist pattern shown, it can be seen that the thinnest width of the photoresist pattern of the pr...

Embodiment 3

[0061] A preparation of an inorganic photoresist composition and patterning thereof, comprising the steps of:

[0062] 1) Add 0.2 mL of methyl isobutyl ketone dissolved with 15 mg of photoacid generator diphenyliodonium hexafluorophosphate into 1 mL of HSQ, and the system is protected from light to obtain a photoresist solution.

[0063] 2) The photoresist solution was filtered three times with a filter membrane with a pore size of 0.22 μm to remove impurities, and a photoresist composition P was obtained.

[0064] The prepared photoresist composition P is used for photoresist patterning, comprising the steps of:

[0065] A) Dropping an appropriate amount of photoresist composition P on the glass substrate, spin-coating at 500 rpm for 5 seconds and 4000 rpm for 60 seconds to obtain a photoresist film with good film-forming properties.

[0066] B) Bake the obtained photoresist film on a hot plate at 50° C. for 10 minutes, then raise the temperature to 100° C. and bake for 3 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com