In-situ Oxygen Generation Ozone Enhanced Three-stage Electrochemical Water Treatment Equipment and Water Treatment Method

A kind of water treatment equipment, electrochemical technology, applied in the direction of oxidation water/sewage treatment, water/sewage treatment equipment, chemical instruments and methods, etc., can solve the problem of low oxidation reaction rate, slow mass transfer of reaction system, pollution of atmospheric environment, etc. problems, to achieve the effect of streamlining equipment, improving processing energy efficiency, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

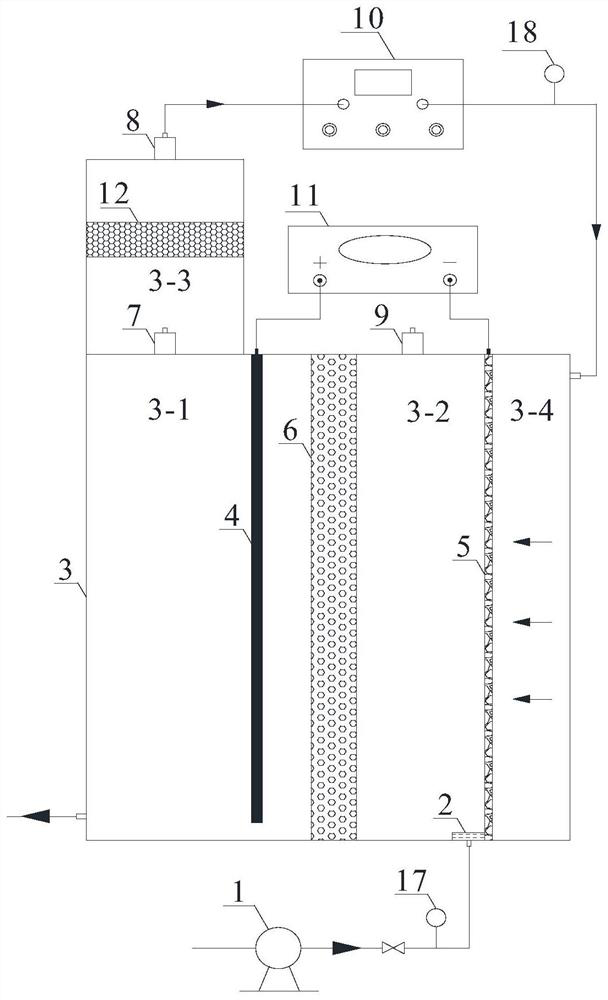

[0033] A three-stage electrochemical water treatment equipment for in-situ oxygen generation and ozone enhancement, such as figure 1 As shown, comprise water inlet device 1 (in the present embodiment, be water inlet pump), reaction device 3, oxygen storage chamber 3-3, and be located at the anode 4 inside reaction device 3, negative electrode 5 and water-permeable gas barrier catalytic layer 6; The negative electrode 5 and the water-permeable and gas-insulating catalytic layer 6 are all airtightly connected with the inner wall of the reaction device 3, and the internal space of the reaction device 3 is divided into an anode chamber 3-1, a cathode chamber 3-2 and a cathode inlet chamber 3-4, and the anode 4 Located in the anode chamber 3-1, the oxygen storage chamber 3-3 is located at the top of the anode chamber 3-1 and communicates with it; the gas outlet of the oxygen storage chamber 3-3 passes through the ozone generator 10 and the cathode inlet chamber 3-4 The air inlet is...

Embodiment 2

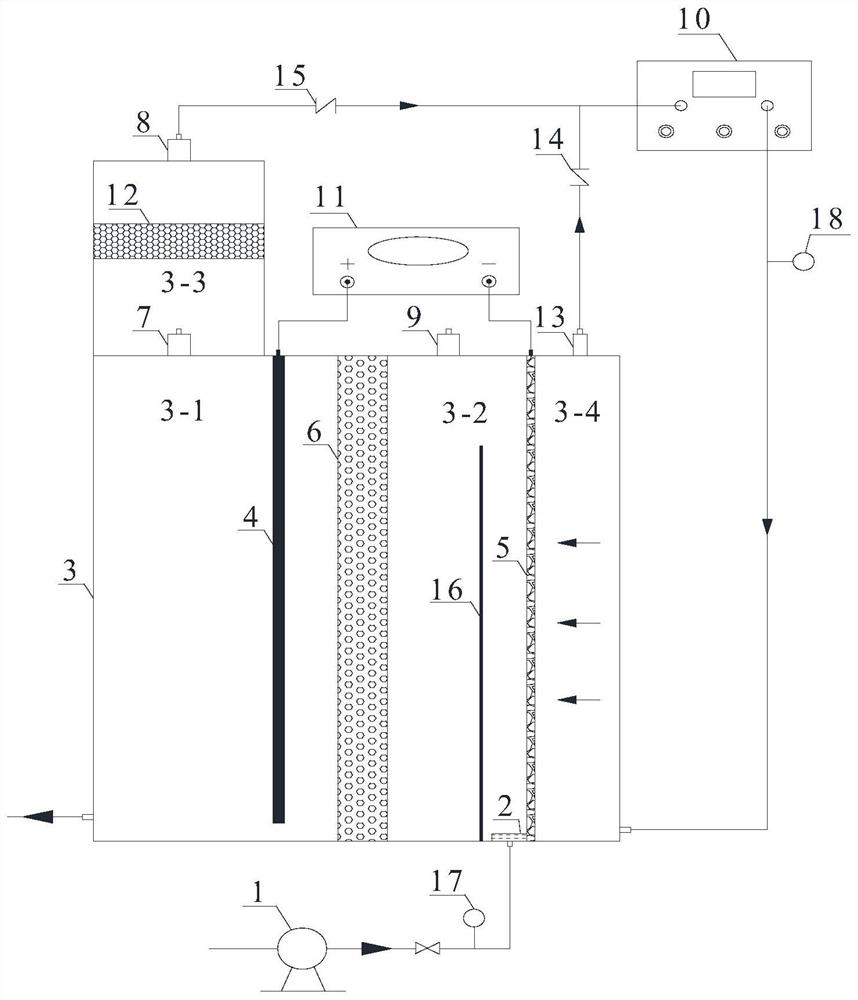

[0042] Equipment for in-situ oxygen generation and ozone enhanced three-stage electrochemical water treatment, see figure 2 , is basically the same as Embodiment 1, except that it also includes a gas pressure valve 13 located at the top of the cathode inlet chamber 3-4, and a No. 1 gas check valve 14 and a No. 2 gas check valve 15. When the intake air flow and pressure are too large, the air pressure valve 13 is opened, so that the gas in the cathode air intake chamber 3-4 is returned to the ozone generator 10 air intake. In this way, on the one hand, it is ensured that the cathode 5 can efficiently complete non-bubble or micro-bubble gas distribution and reaction, improve the utilization rate of ozone, and reduce the pollution of ozone tail gas; The No. 1 gas check valve 14 is located in the middle of the gas outlet of the oxygen storage chamber 3-3 and the air inlet of the ozone generator 10, preventing the gas from flowing back from the pressure valve 13 to the air inlet o...

Embodiment 3

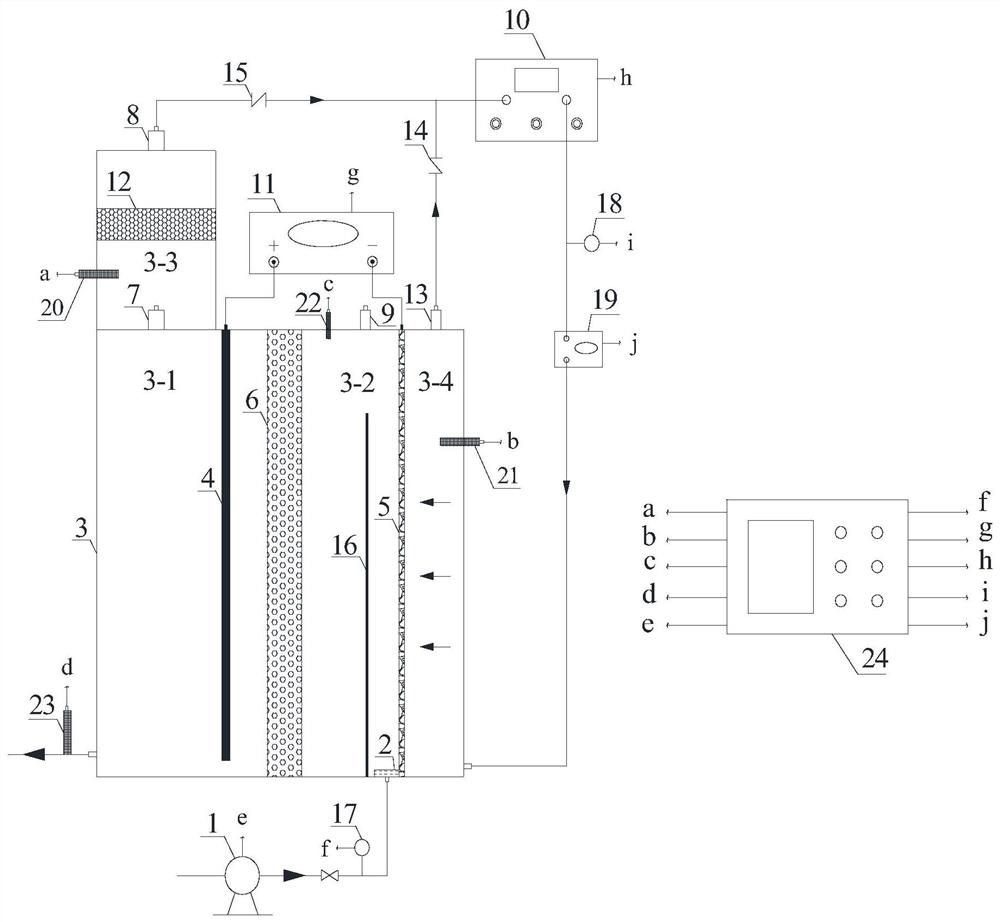

[0045] Equipment for in-situ oxygen generation and ozone enhanced three-stage electrochemical water treatment, see image 3 , is basically the same as Embodiment 2, the difference is only in that it also includes an ozone concentration monitor 19, a No. 1 air pressure sensor 20, a No. 2 air pressure sensor 21, a total oxide concentration monitoring probe 22, a residual oxide concentration monitoring probe 23 and An automatic control unit 24 for controlling each component;

[0046] The ozone concentration monitor 19 is located between the ozone generator 10 and the cathode air inlet chamber 3-4, and is used to monitor the gas phase ozone concentration added; No. 1 air pressure sensor 20 is placed on the side wall of the oxygen storage chamber 3-3 for Monitor the air pressure in the oxygen storage chamber 3-3; No. 2 air pressure sensor 21 is placed on the side wall of the cathode air intake chamber 3-4 for monitoring the air pressure in the cathode air intake chamber 3-4; the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com