Boride-silicon carbide multiple phase ceramic and its preparation method

A multiphase ceramic and boride technology, applied in the field of non-oxide multiphase ceramics, can solve the problem that a single boride ceramic cannot meet the requirements at the same time, achieve excellent mechanical properties and thermal properties, strong industrial practicability, and reduce the sintering temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

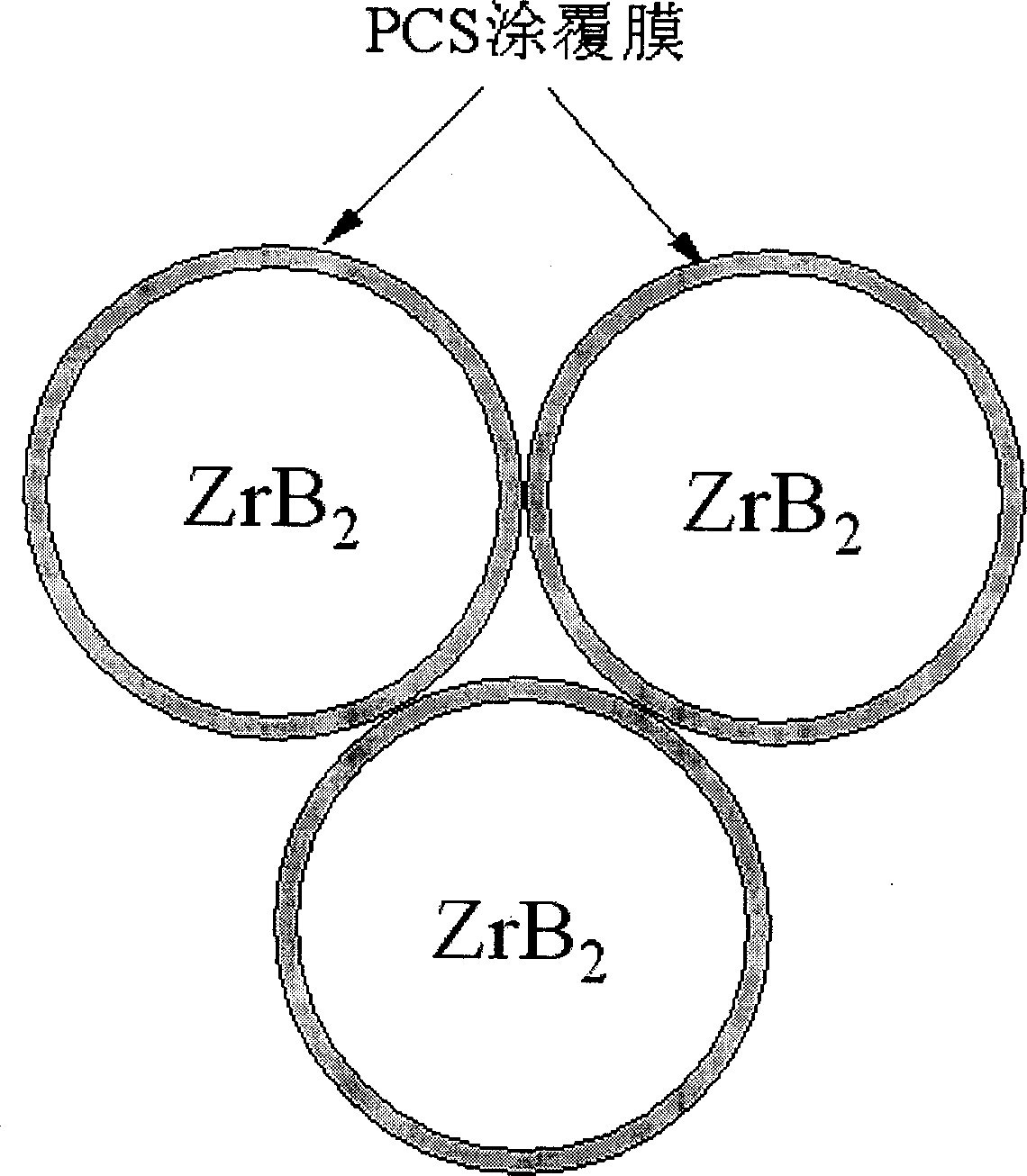

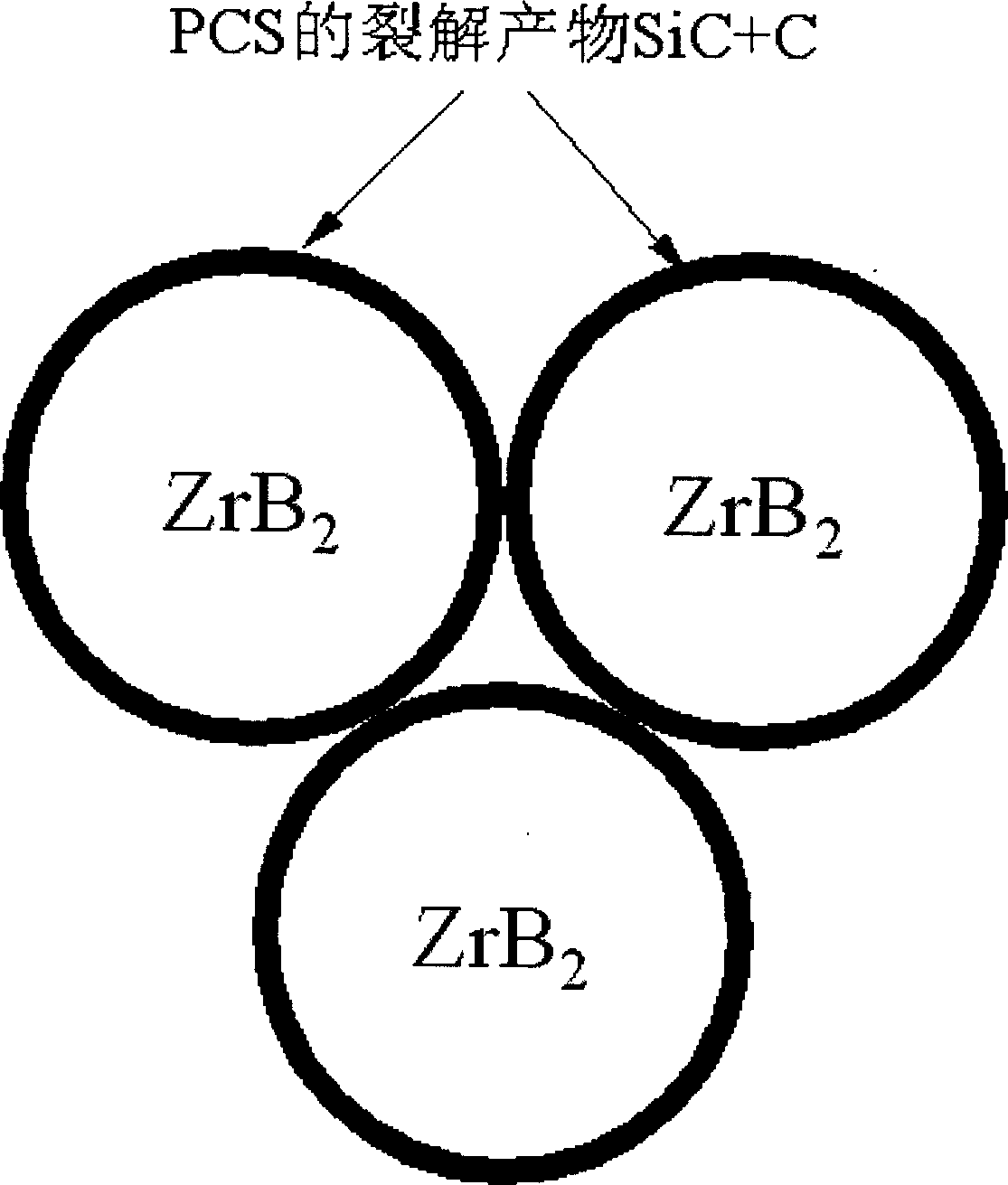

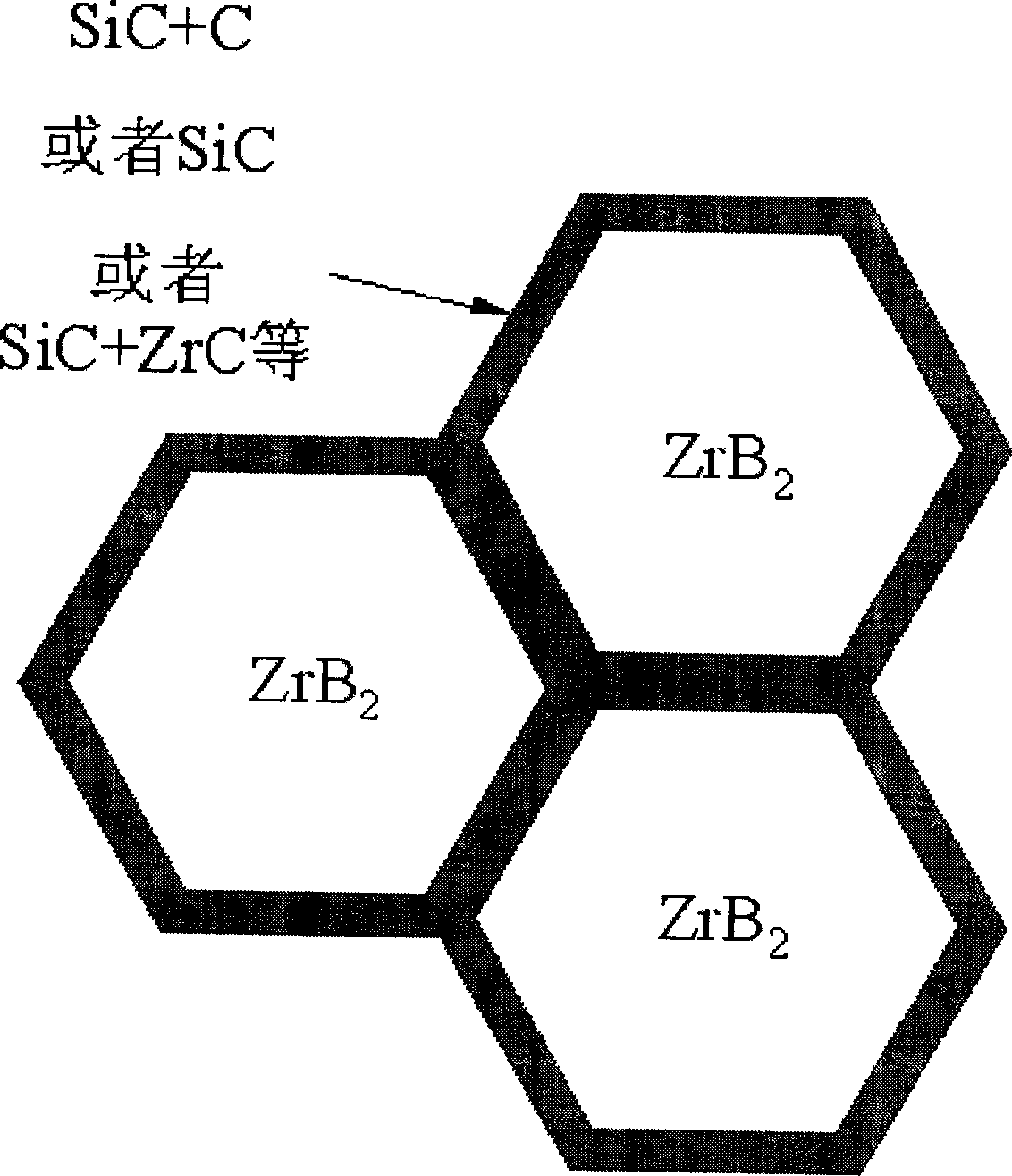

[0041] For the preparation of ZrB-containing 2 -Composite material with (SiC+C)20% volume content, ZrB 2 Add 8.8 grams of powder into the gasoline solution dissolved with 1.2 grams of PCS, mix and grind with zirconia balls for 12 hours, then pour it into a shallow container while stirring to vaporize the gasoline, and obtain coated ZrB 2 powder. The coated powder is pyrolyzed at 800° C. in a flowing argon atmosphere to obtain ceramic mixed powder. Then put the powder into a graphite mold and sinter by hot pressing at 1800° C. in an argon protective atmosphere with a hot pressing pressure of 20 MPa and a holding time of 60 min. The properties of the obtained materials are listed in Table 1.

Embodiment 2

[0043] For the preparation of ZrB-containing 2 -Composite material with (SiC+C) 20% volume content, 1.2 grams of PCS powder is directly mixed with 8.8 grams of ZrB 2 Powder mix. The mixed powder is cracked at 800° C. in a flowing argon atmosphere to obtain ceramic mixed powder. Then put the powder into a graphite mold and sinter by hot pressing at 1800° C. in an argon protective atmosphere with a hot pressing pressure of 20 MPa and a holding time of 60 min. The properties of the obtained materials are listed in Table 1.

Embodiment 3

[0045] Samples were obtained in exactly the same manner as in Example 1, except that they were hot-pressed and sintered at 1700°C. The properties of the obtained materials are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com