Preparation method of 2050 aluminium-lithium alloy fine-grain plate

A technology of aluminum-lithium alloy and plate, which is applied in the field of preparation of 2050 aluminum-lithium alloy fine-grained plate, can solve the problems of reduced dislocation density and coarse grain, and achieve the effect of suppressing cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

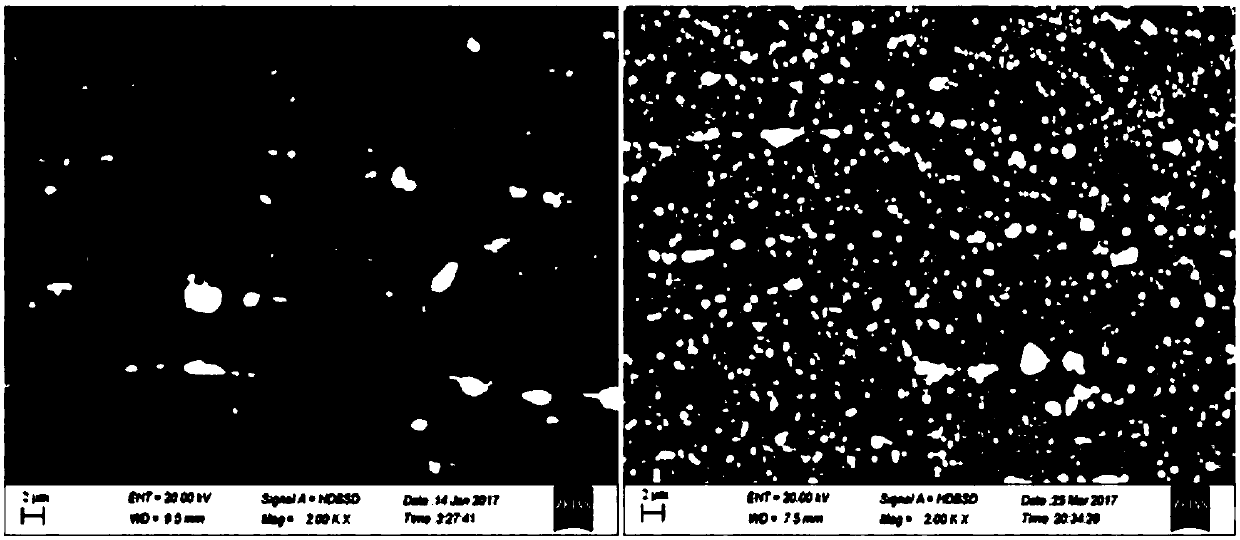

Image

Examples

Embodiment 1

[0037] A 25mm thick 2050 aluminum-lithium alloy hot-rolled plate is selected, and the plate is first subjected to solid solution at 520°C / 3h, and then water quenched. Then pre-deformation is carried out at room temperature, the total pre-deformation amount is 40%, and the deformation amount of each pass is 10-30%. After pre-deformation, carry out 48h overaging treatment at 400°C. Then keep the temperature at 200°C for 2 hours, and roll to 2mm, the total deformation is 92%, and the deformation per pass is 10-30%. Finally, recrystallization annealing was performed at 470°C / 30min in a salt bath furnace to obtain the final 2050 Al-Li alloy fine-grained plate.

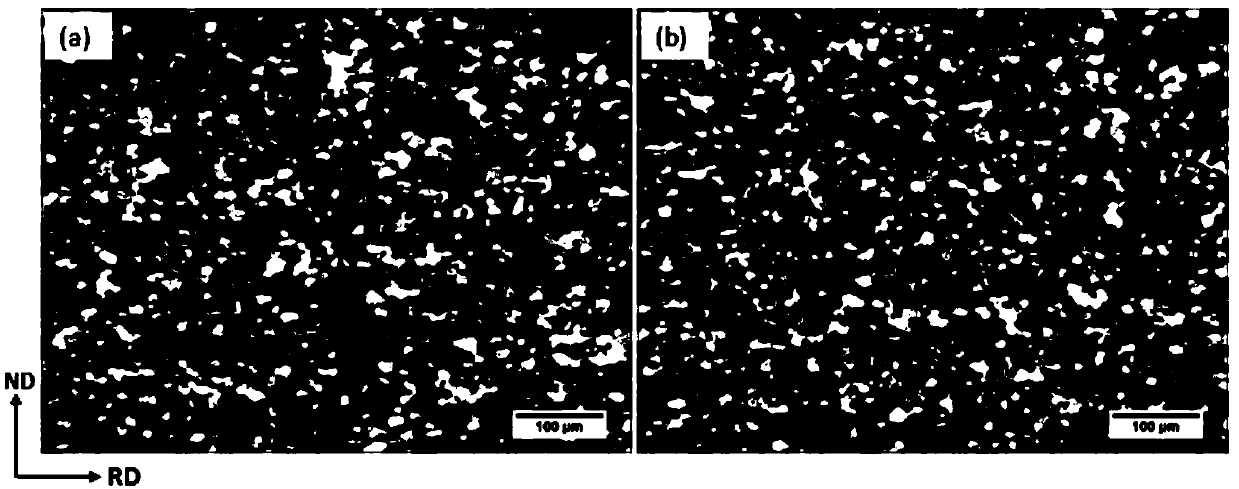

[0038] The macrophotograph of the prepared 2050 Al-Li alloy fine-grained plate is shown in figure 2 .

[0039] The grain structure picture of the longitudinal section of the 2050 Al-Li alloy fine-grained plate after recrystallization annealing is shown in image 3 , it can be seen that the grain structure is uniform fine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com