Preparation method of transitional metal doped molybdenum disulfide sodium battery negative electrode material and obtained material and application thereof

A negative electrode material and transition metal technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as difficult to meet the requirements of sodium ion batteries, unsatisfactory rate performance, complicated preparation methods, etc., and achieve good ion deintercalation and transmission capabilities , good cycle stability, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

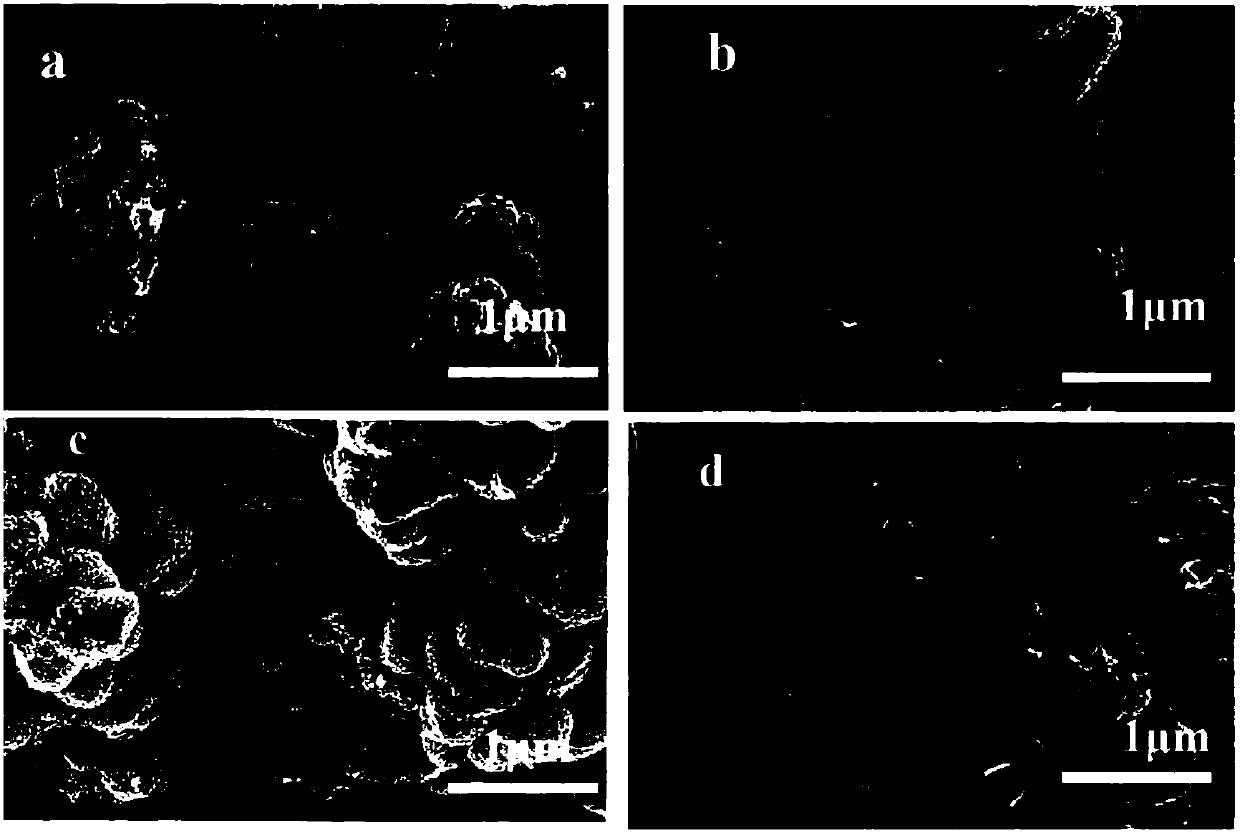

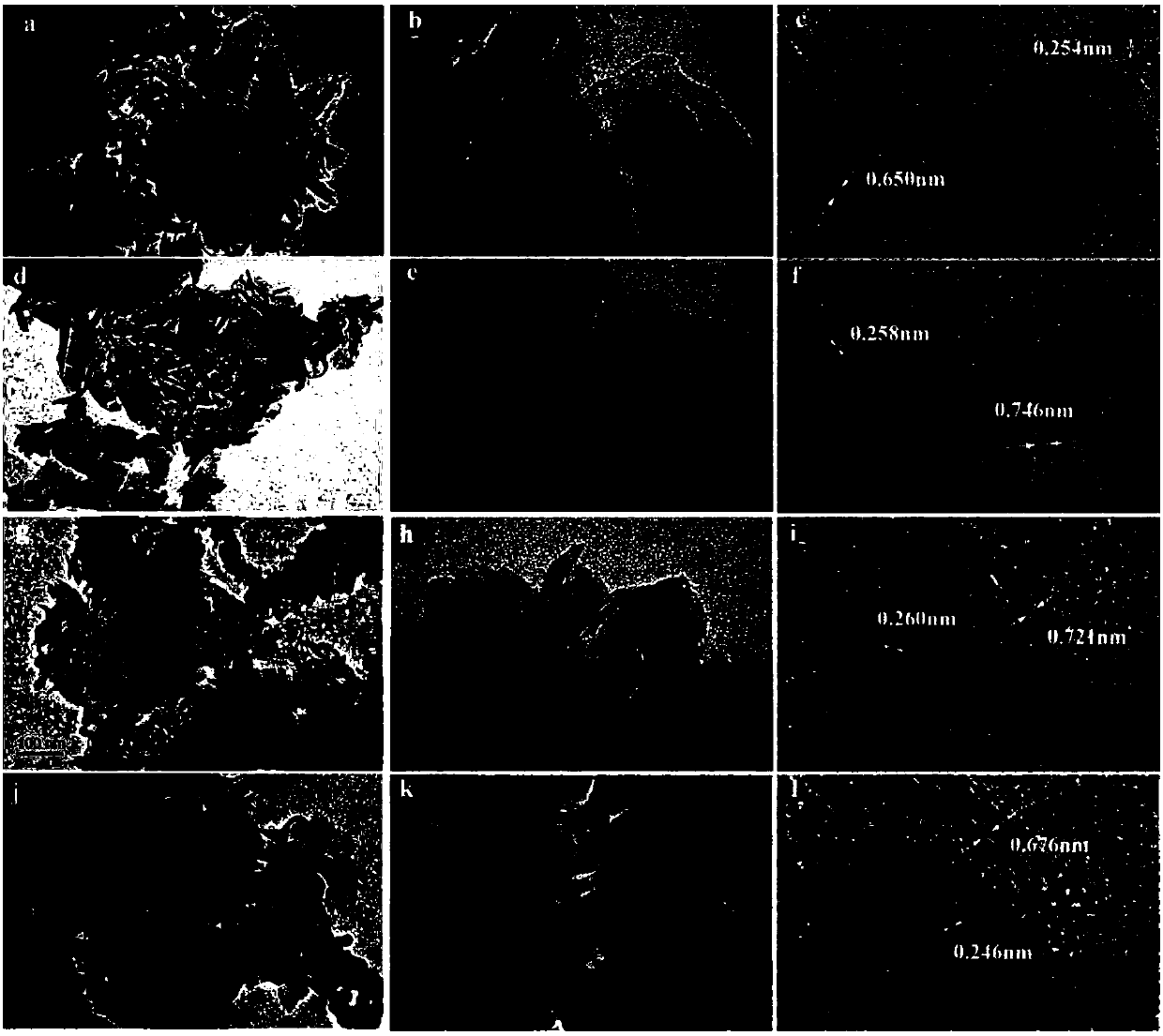

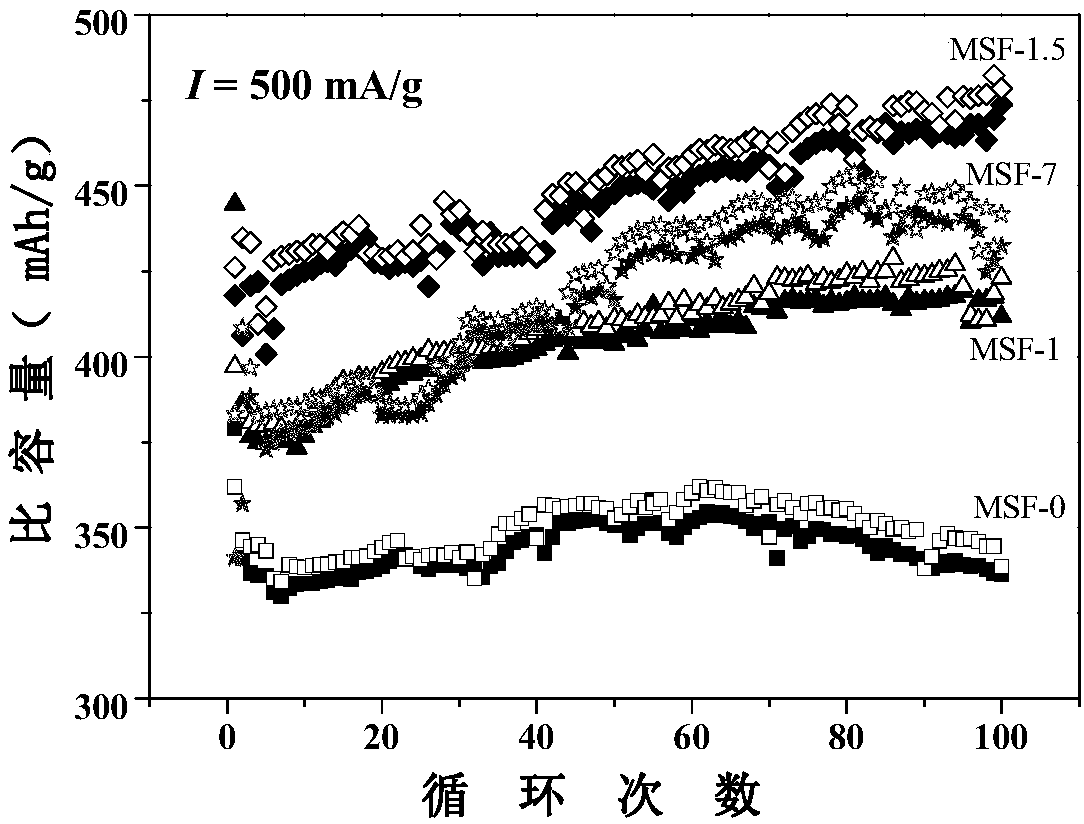

Method used

Image

Examples

Embodiment 1

[0035] (1) Add 0.5g MoCl to 50mL ethanol 5 , 1.67g thiourea and 0.003g anhydrous FeCl 3 (wherein the molar ratio of molybdenum source and sulfur source is 1:12, and the molar ratio of transition metal salt and molybdenum source is 1:100), ultrasonic stirring obtains brown-red solution A;

[0036] (2) The solution A was magnetically stirred in the air for 2 days to obtain a uniform brown gel;

[0037] (3) Move the brown gel and the flask to a vacuum drying oven, and dry continuously in vacuum at 100°C for 2 hours to form a brown powder;

[0038] (4) Subsequently, the powder obtained in step (3) was scraped off and taken out. After grinding, it was transferred to a tube furnace and sintered at a high temperature under an Ar inert atmosphere at a temperature of 600° C. for 3 hours to prepare the transition metal-doped bismuth Molybdenum sulfide sodium battery negative electrode material;

[0039] (5) Mix the dried composite material with carbon black and carboxymethyl cellulos...

Embodiment 2

[0041] Same as Example 1, the difference is anhydrous FeCl 3 The mass of is 0.0045g (the molar ratio of transition metal salt to molybdenum source is 1.5:100).

Embodiment 3

[0043] Same as Example 1, the difference is anhydrous FeCl 3 The mass of is 0.0208g (the molar ratio of transition metal salt to molybdenum source is 7:100).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com