Preparation method of novel nano-silver conductive adhesive

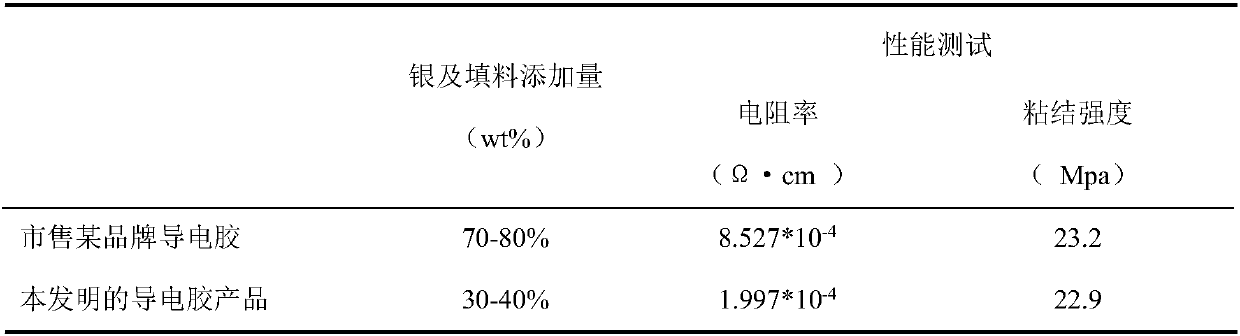

A nano-silver, conductive adhesive technology, applied in the field of conductive adhesive, can solve the problems of affecting the comprehensive performance and application of conductive adhesive, difficult to disperse uniformly, poor compatibility of matrix, etc., to reduce surface tension, enhance impact resistance and shear resistance. Performance, interface contact enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] First, the carbon nanotubes are modified, and the treatment process includes the following steps:

[0023] 1) Alkali treatment: After the carbon nanotubes are jet milled, they are mixed with sodium deoxycholate and a sodium hydroxide solution with a mass concentration of 0.1%. The mass ratio range of carbon nanotubes to sodium deoxycholate is 1 : 0.5, the mixed solution was stirred by a high-speed disperser for 1h after ultrasonication for 30min, filtered, and the filtrate was pulverized by a jet mill, and then in N 2 Under the protection of the atmosphere, react at 600°C for 60min, the product is 2 After cooling under the atmosphere, wash with deionized water and filter until neutral, vacuum dry at 40°C to constant weight, and set aside;

[0024] 2) Mix nitric acid with a mass concentration of 68% and sulfuric acid with a mass concentration of 98% at a volume ratio of 1:3, and then add deionized water for dilution. The volume ratio of the amount of deionized water add...

Embodiment 2

[0028] First, the carbon nanotubes are modified, and the treatment process includes the following steps:

[0029] 1) Alkali treatment: After the carbon nanotubes are jet milled, they are mixed with sodium deoxycholate and a sodium hydroxide solution with a mass concentration of 0.5%. The mass ratio range of carbon nanotubes to sodium deoxycholate is 1 : 1. After the mixed solution is ultrasonicated for 30 minutes, continue to stir for 1 hour through a high-speed disperser, filter, and the filtrate is pulverized by a jet mill, and then in N 2 Under the protection of the atmosphere, react at 700°C for 60min, the product is 2 After cooling under the atmosphere, wash with deionized water and filter until neutral, vacuum dry at 40°C to constant weight, and set aside;

[0030] 2) Mix nitric acid with a mass concentration of 68% and sulfuric acid with a mass concentration of 98% at a volume ratio of 1:3, and then add deionized water for dilution. The volume ratio of the amount of de...

Embodiment 3

[0034] First, the carbon nanotubes are modified, and the treatment process includes the following steps:

[0035] 1) Alkali treatment: After the carbon nanotubes are jet milled, they are mixed with sodium deoxycholate and a sodium hydroxide solution with a mass concentration of 0.1%. The mass ratio range of carbon nanotubes to sodium deoxycholate is 1 : 1.5, after the mixture was ultrasonicated for 60min, it was stirred for 1h by a high-speed disperser, filtered, and the filtrate was pulverized by a jet mill, and then in N 2 Under the protection of the atmosphere, react at 800°C for 30min, and the product is 2 After cooling under the atmosphere, wash with deionized water and filter until neutral, vacuum dry at 40°C to constant weight, and set aside;

[0036] 2) Mix nitric acid with a mass concentration of 68% and sulfuric acid with a mass concentration of 98% at a volume ratio of 1:3, and then add deionized water for dilution. The volume ratio of the amount of deionized water...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com