Composite solid electrolyte and preparation method thereof, and solid lithium battery and preparation method thereof

A technology of solid electrolyte and solid lithium, which is applied in the manufacture of electrolyte batteries, composite electrolytes, non-aqueous electrolyte batteries, etc., can solve the problems of low decomposition voltage, small number of ion migration, poor ability to dissolve lithium salts, etc., to achieve small interface resistance, The effect of high ion transfer number and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The invention provides a method for preparing a composite solid electrolyte, comprising the following steps:

[0040] Dissolving at least one polymer of polycaprolactone and polycaprolactone derivatives and lithium salt in an organic solvent to obtain a first solution;

[0041] adding garnet oxide to the first solution, and mixing to obtain a second solution;

[0042] The second solution is cast and dried to obtain a composite solid electrolyte.

[0043]The above-mentioned preparation method is explained in detail below.

[0044] The polycaprolactone derivatives involved are polystyrene-polycaprolactone, polyethylene oxide-polycaprolactone, polyvinylidene fluoride-polycaprolactone, polyacrylonitrile-polycaprolactone, perfluoropolyether - at least one of polycaprolactone, polymethacrylic acid-polycaprolactone, polydimethylsiloxane-polycaprolactone.

[0045] The lithium salt is selected from lithium bistrifluoromethylsulfonylimide, lithium bisfluorosulfonimide, lithium...

Embodiment 1

[0076] A method for preparing a composite solid electrolyte, comprising the steps of:

[0077] S11. 1 g of polycaprolactone (PCL) and 0.25 g of LiFSI were dissolved in acetonitrile solvent and mixed uniformly to obtain a first solution.

[0078] S12. Add 0.139g Li 6.4 La 3 Zr 1.4 Ta 0.6 o 12 Add to the first solution obtained in step S11, and mix well to obtain the second solution.

[0079] S13. Cast the second solution obtained in step S12 into a polytetrafluoroethylene container, then place it in a vacuum drying oven, and dry it at 80° C. for 12 hours to obtain a composite solid electrolyte.

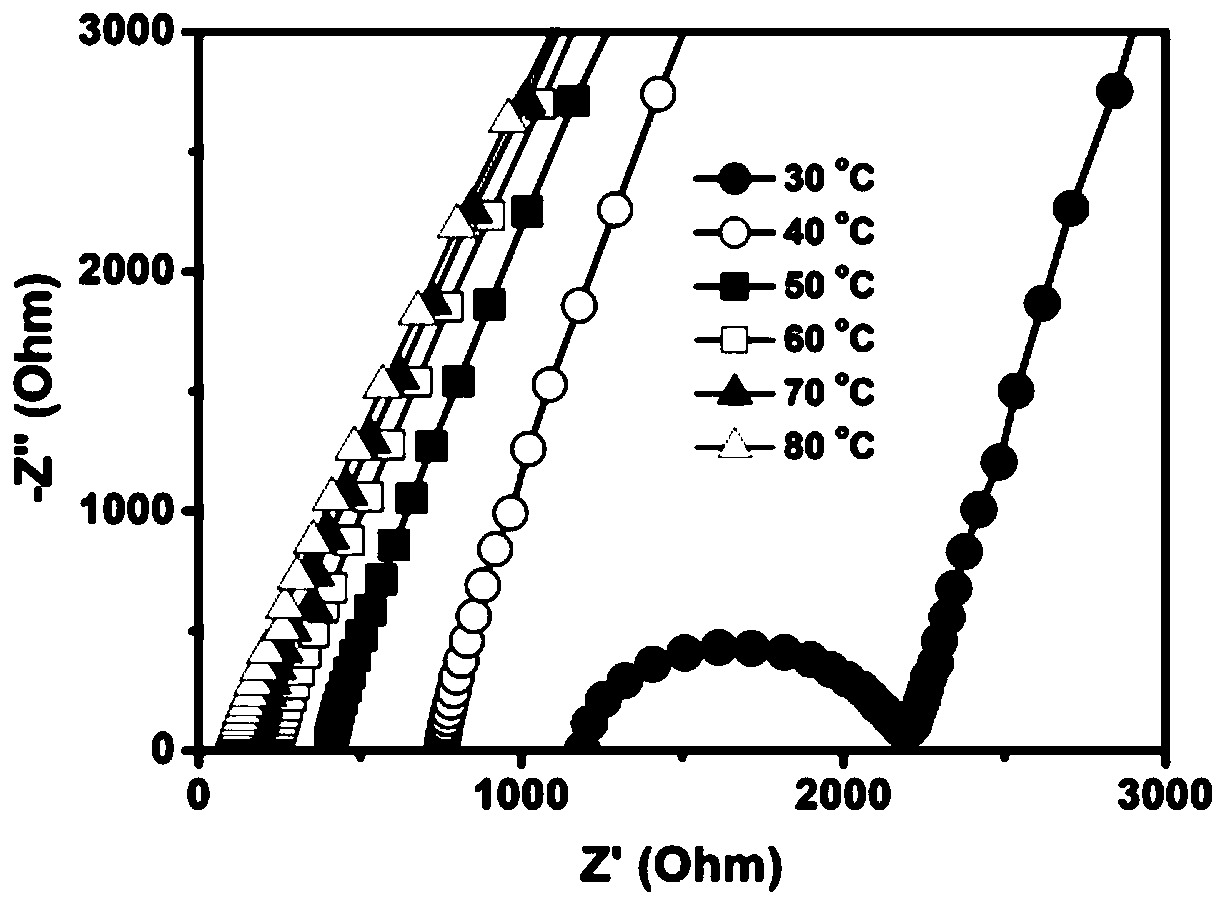

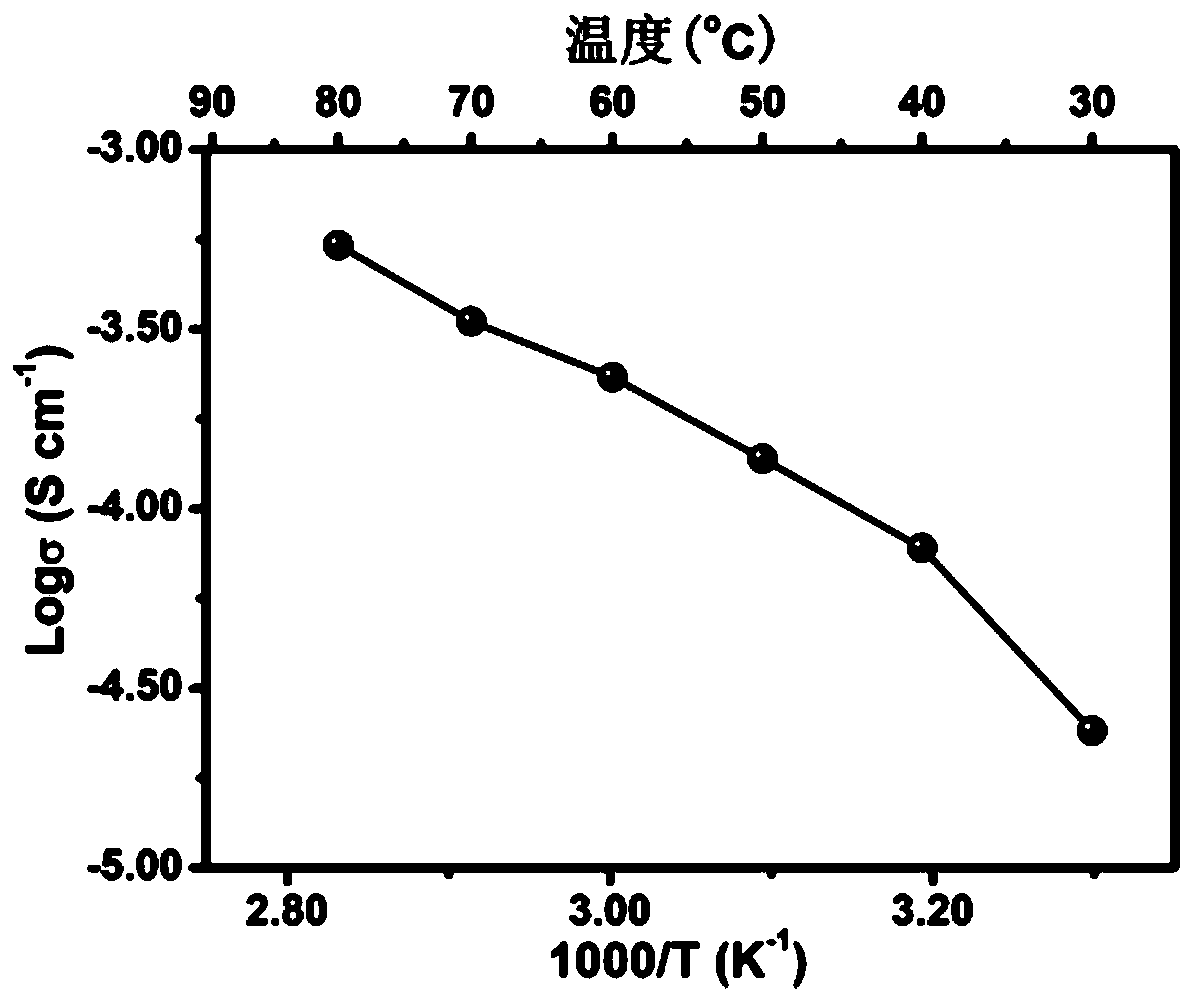

[0080] The composite solid electrolyte obtained in Example 1 is tested for mechanical properties, AC impedance and ionic conductivity, electrochemical window and ion migration number, wherein:

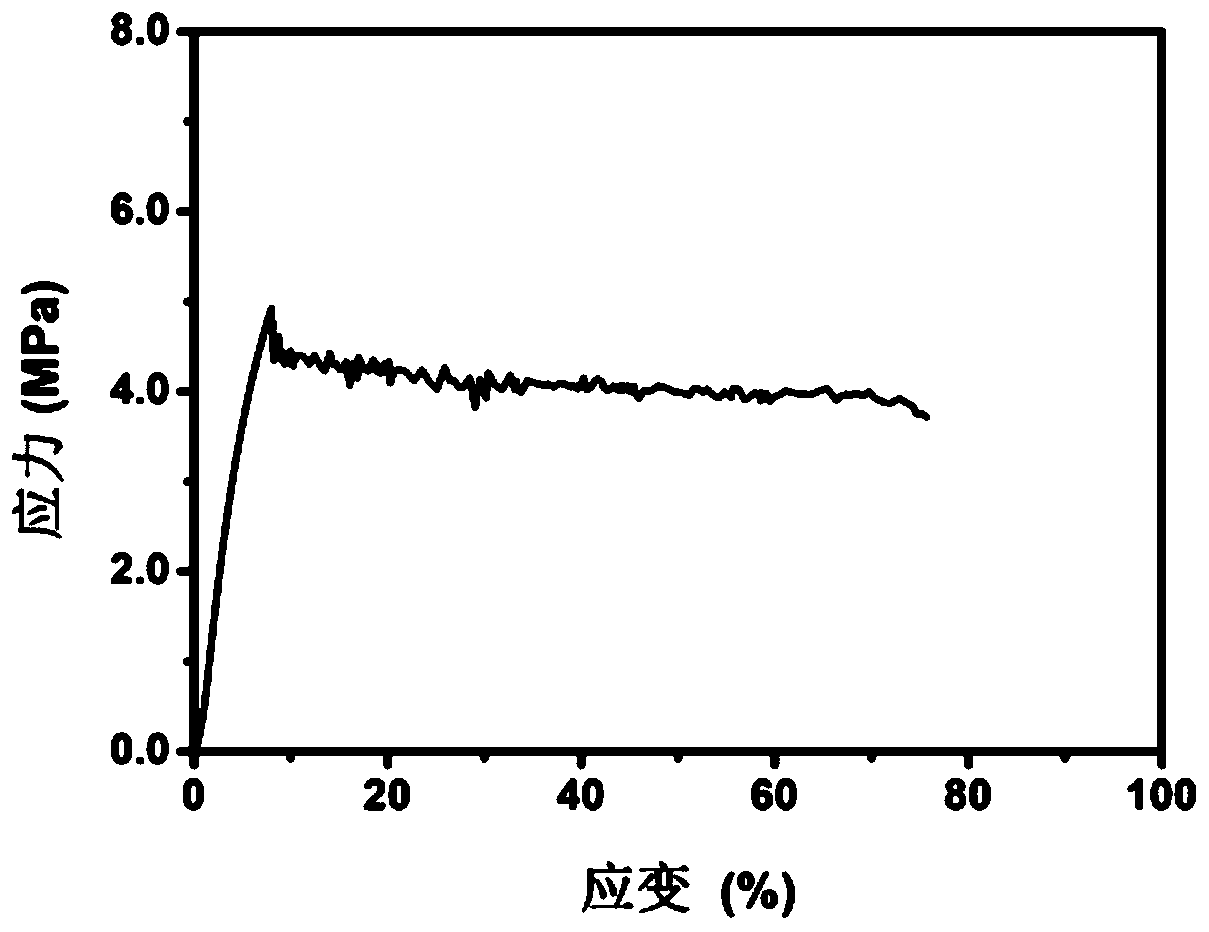

[0081] (1). Stress-strain curve: using the conventional stress-strain measurement method, the test results are as follows figure 1 shown.

[0082] from figure 1 It can be seen that whe...

Embodiment 2

[0092] A method for preparing a composite solid electrolyte, comprising the steps of:

[0093] S21. Dissolving 1 g of polycaprolactone (PCL) and 0.5 g of LiFSI in tetrahydrofuran solvent and mixing them uniformly to obtain a first solution.

[0094] S22. Add 0.22g Li 5 La 3 Ta 2 o 12 Add to the first solution obtained in step S21, and mix well to obtain a second solution.

[0095] S23. Cast the second solution obtained in step S22 into a polytetrafluoroethylene plate, then place it in a vacuum drying oven, and dry it at 60° C. for 15 hours to obtain a composite solid electrolyte.

[0096] According to the test method of Example 1, the composite solid electrolyte obtained in Example 2 was subjected to corresponding performance tests. After testing, at 60°C, the ionic conductivity of the composite solid electrolyte is 1.5×10 -4 S / cm, the decomposition voltage is 4.7V, and the ion migration number is 0.543.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com