Material with steady resistance-vary feature as well as resistance-vary memory

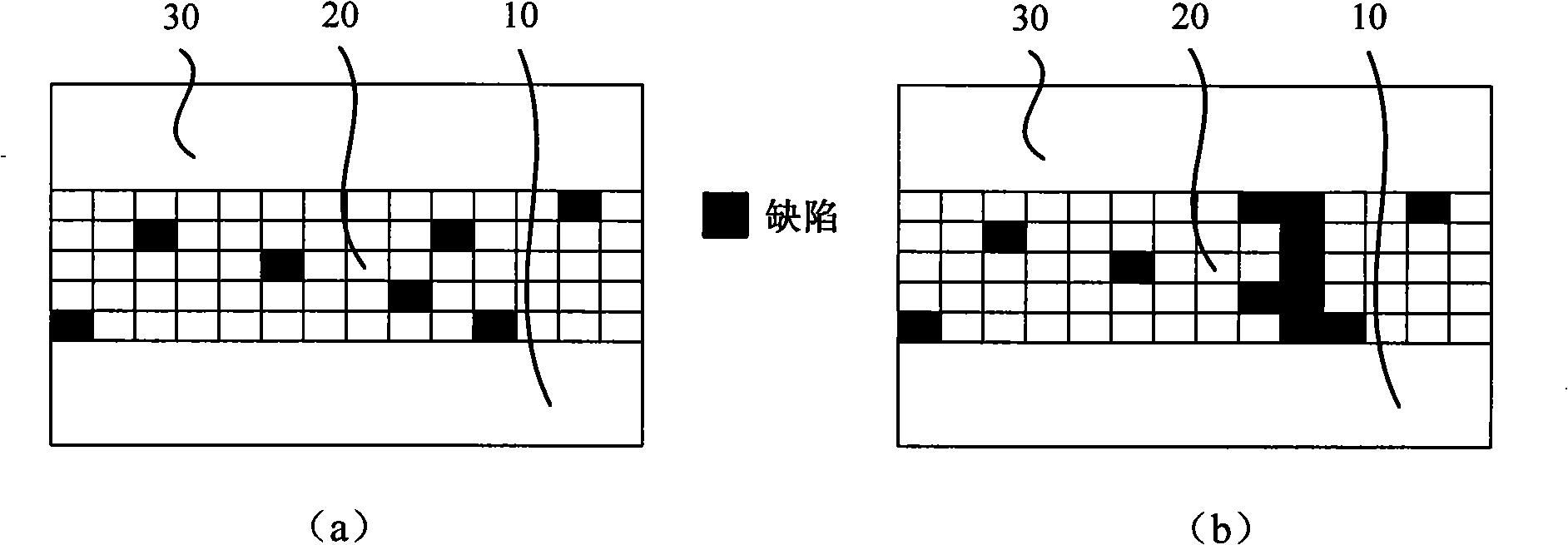

A technology of resistive memory and resistive characteristics is applied in the field of resistive materials, which can solve the problems of unstable resistance value in high and low resistance states, hindering further application of resistive memory, and difficulty in precise control of resistive memory.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preparation of the resistive memory of the present invention will be further described in detail in conjunction with the accompanying drawings:

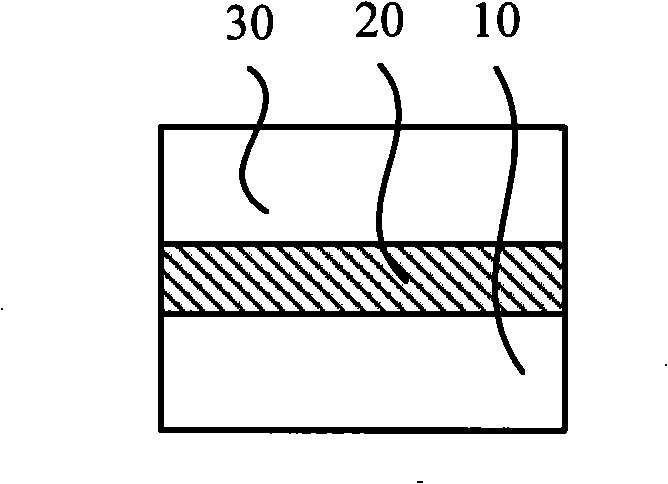

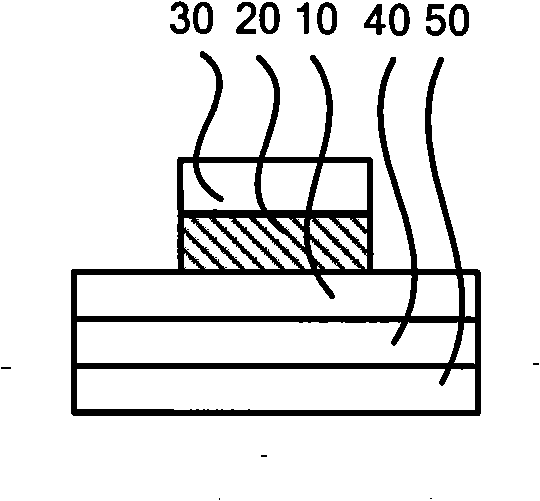

[0024] refer to image 3 , on the SiO on the silicon substrate 50 2 On the insulating medium 40, use PVD (Physical Vapor Deposition) method to grow TiN, HfN or IrO 2 Bottom electrode 10 . On the bottom electrode, grow HfO doped with +3 valent metal element ions by PLD (Pulsed Laser Deposition) method 2 , ZrO 2 or CeO 2 oxide film. The specific manufacturing process is that for PLD to grow doped oxide targets, it is necessary to mix the above-mentioned oxide fine powder and the oxide fine powder of the desired metal element to be mixed evenly, and the above-mentioned mixture is mixed at a temperature of 0.15mbar to 0.25mbar. After being pressed under pressure for 4-8 minutes, it is made by sintering at a high temperature of 900-1200 degrees Celsius for 20-30 hours. The laser power of the PLD is 250mW-350mW, and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com