Pool cleaner

a technology for cleaning and pool water, applied in the field of pool cleaners, can solve the problems of wasting energy of bypassed flow, reducing the service life of pool cleaners, so as to achieve the shallowness at which they will operate and the limitations of their ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

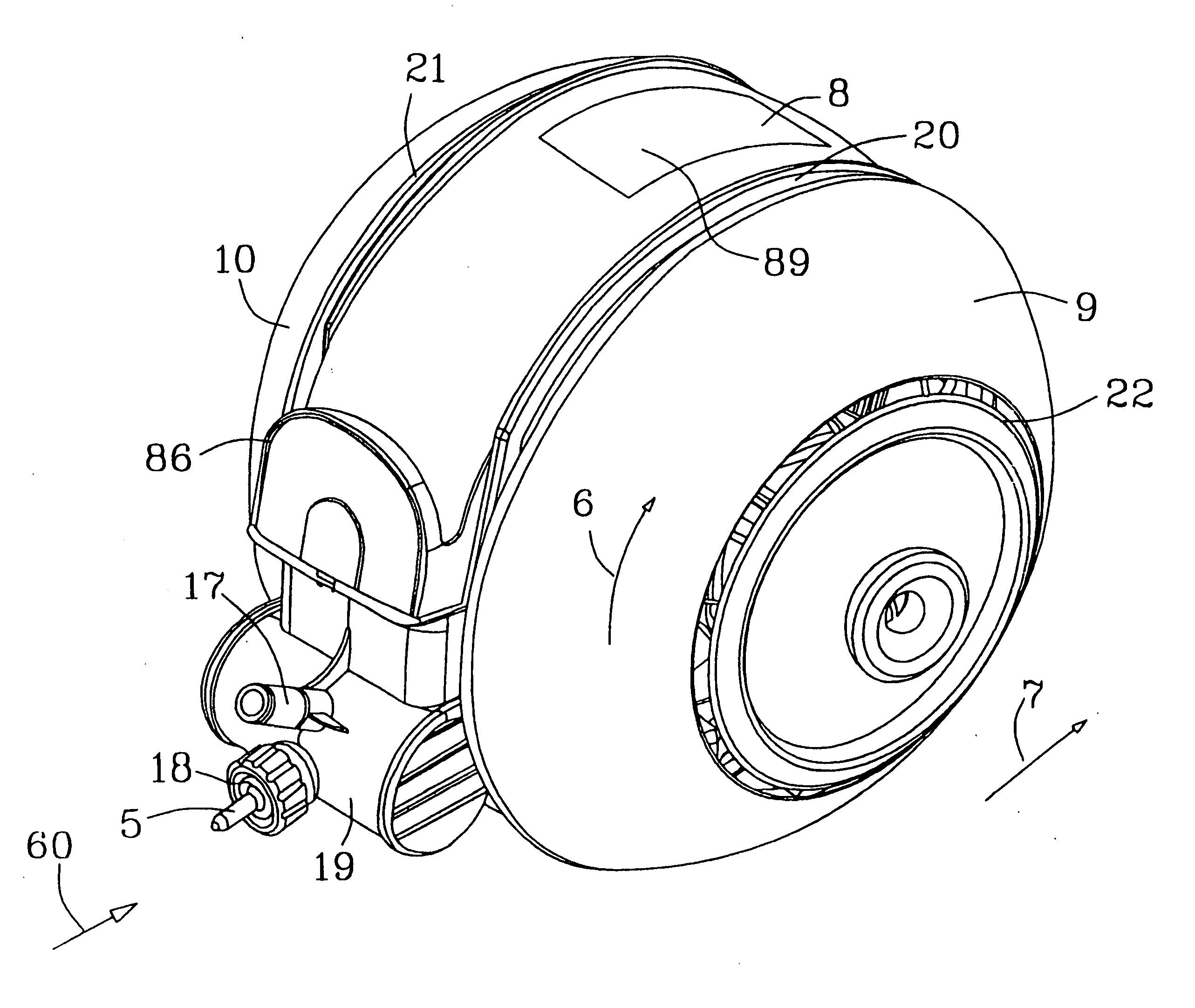

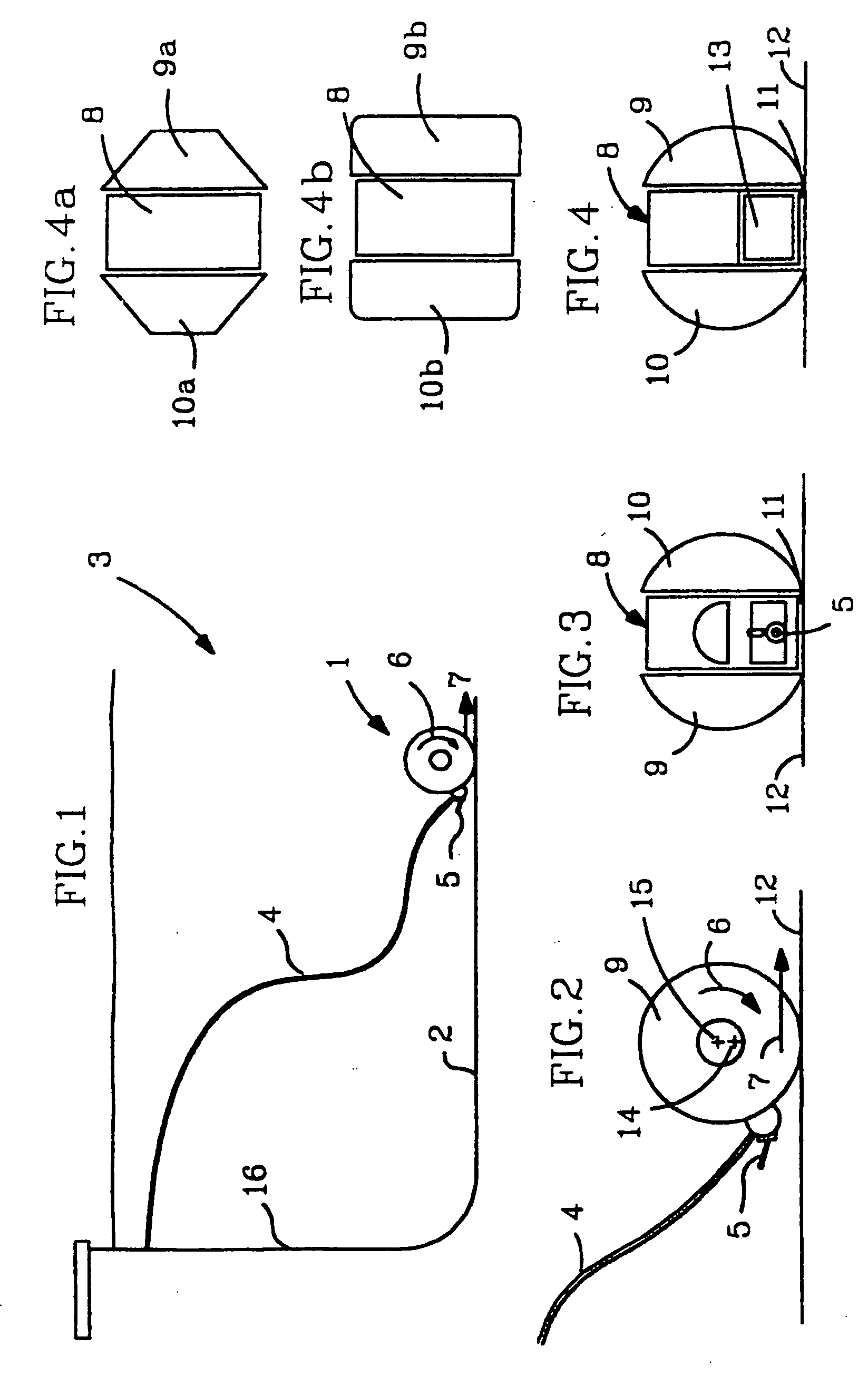

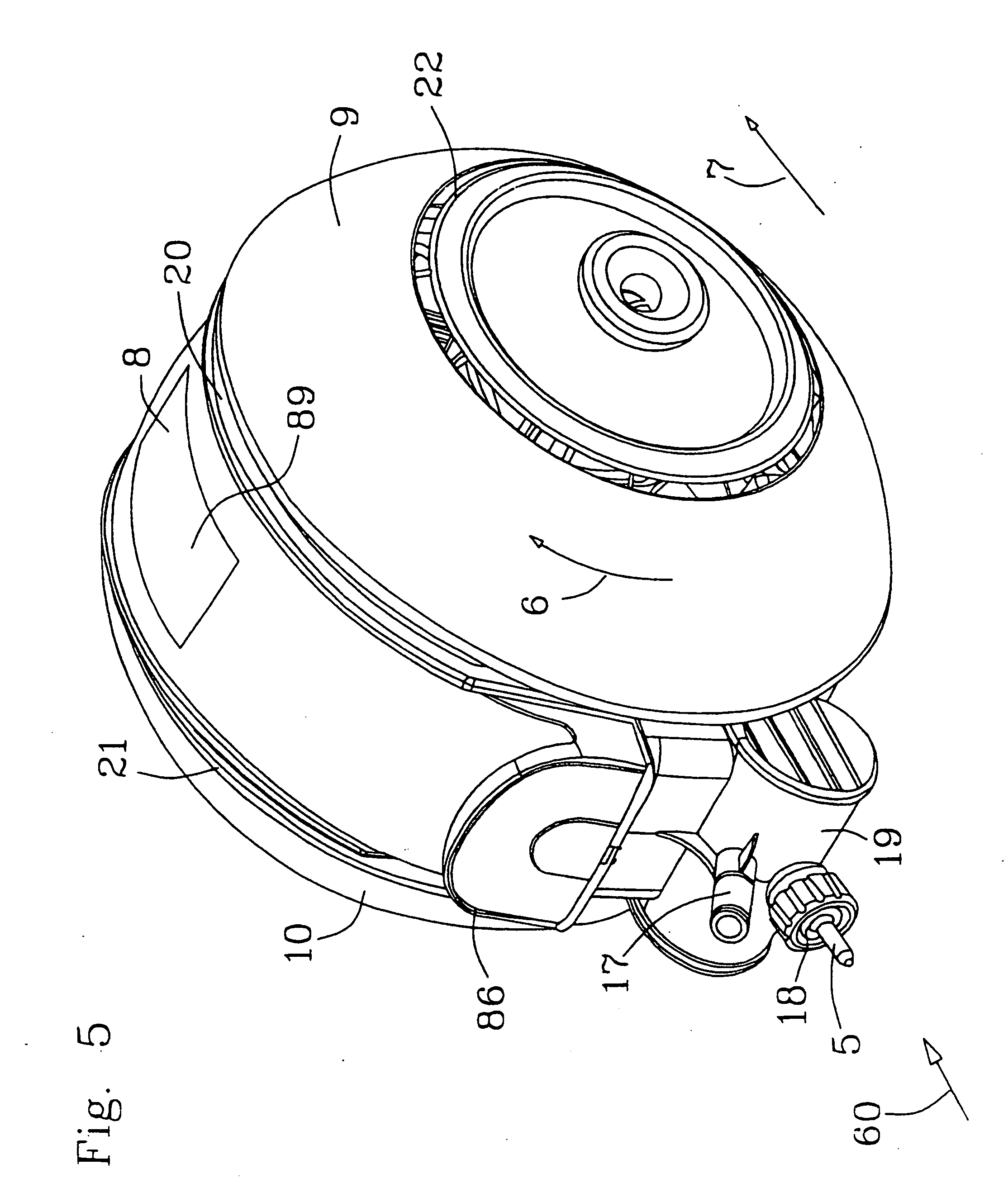

[0060]FIG. 1 schematically shows a push side cleaner 1 located on a bottom surface 2 of a pool 3. The pool cleaner 1 has a hose 4 connected to the push side of a water circulation system which circulates and filters water for the pool. The pool cleaner 1 has a nozzle 5 which jets water rearwardly of the pool cleaner so as to assist in propelling it along the pool surface and the nozzle is mounted in a ball joint so that it can be angled, or it can be manufactured in a fixed angle position, as shown by reference numeral 85 in FIG. 17. The angle of the nozzle may be made suitable also to press the pool cleaner to some extent onto the surface of the pool along which it is moving. The pool cleaner moves by rotation of the outer segments of the cleaner in the direction indicated by the arrow 6 so that the pool cleaner moves along the pool surface in the direction indicated by the arrow 7.

[0061] As shown in FIGS. 2, 3 and 4 the push side pool cleaner is generally spheroidal in shape of i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com