Graphene/WSe2/NiFe-LDH aerogel and preparation thereof

A graphene and aerogel technology, applied in the field of graphene/WSe2/NiFe-LDH aerogel and its preparation, can solve the problems of volume shrinkage of active substances, poor cycle stability, and unsatisfactory performance, and reduce the Agglomeration, excellent electrochemical performance, easy mass production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

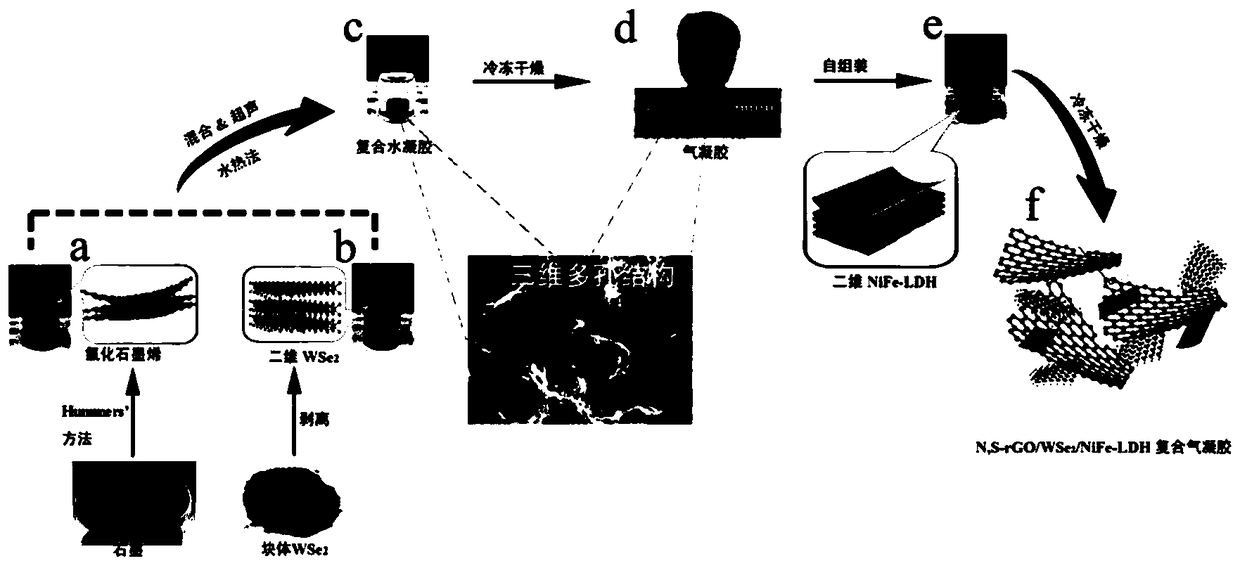

[0040] like figure 1 Shown, the N, S co-doped graphene / WSe of preferred embodiment of the present invention 2 The preparation method of / NiFe-LDH comprises:

[0041] S1, ultrasonically disperse graphite oxide in deionized water to prepare a graphene oxide lamellar dispersion. Preferably, the concentration of the prepared graphene oxide dispersion is 0.5-3mg mL -1 , more preferably 2mg mL -1 .

[0042] Specifically, the graphite oxide is prepared by the following method:

[0043] S11, under ice bath and vigorous stirring, NaNO 3 Dissolve in concentrated sulfuric acid until NaNO 3 completely dissolved.

[0044] For example: adding concentration to the three-necked reaction flask is 98% concentrated sulfuric acid (H 2 SO 4 ), and the reaction bottle was placed in an ice-water bath and stirred at 150rpm, adding NaNO 3 , continue to stir under the ice-water bath. Wherein, the concentrated sulfuric acid and NaNO 3 The weight ratio is: 60:1~100:1.

[0045] S12, maintain i...

Embodiment 1

[0073] A N, S co-doped graphene / WSe 2 / NiFe-LDH preparation method, such as figure 1 shown, including:

[0074] (1) Preparation of graphene oxide (GO) dispersion: disperse 100 mg of the graphite oxide prepared above in 100 mL of deionized water, and sonicate for 1 hour to obtain a tan GO lamellar dispersion with a GO concentration of 2 mg mL -1 .

[0075] (2) Ultra-thin WSe 2 Preparation of nanosheet dispersion: 20 mg bulk WSe 2 Add 4 mL of isopropanol (IPA) / water (V / V, 6 / 4) mixed solvent with a volume fraction of 60%, put it into an ultrasonic instrument and perform ultrasonic vibration treatment with a power of 200W and a frequency of 40kHz 4 Hours, the temperature was kept at room temperature during sonication by adding circulating cooling water. Subsequently, the sonicated solution was centrifuged at 4000 rpm for 20 min to remove unstripped bulk WSe at the bottom 2 , the supernatant obtained is two-dimensional WSe 2 Nanosheets, the concentration of which is about 0....

Embodiment 2

[0086] The reaction and operating conditions of this embodiment and embodiment 1 are basically the same, the difference is that the reducing agent L-cysteine in embodiment 1 is replaced by ascorbic acid.

[0087] The prepared graphene / WSe 2 / Layered NiFe-LDH airgel is tested, and the prepared graphene / WSe 2 / Layered NiFe-LDH airgel has good rate performance, good pseudocapacitive characteristics, and the capacitance value retention rate: 91.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com