Preparation method of antibacterial and wear-proof medical rubber gloves

A technology of rubber gloves and nitrile rubber, used in protective clothing and other directions, can solve the problems of not meeting the requirements of hospital use, poor oil resistance, poor wear resistance, etc., to increase interface compatibility, improve wear resistance, and promote dispersion. and the effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

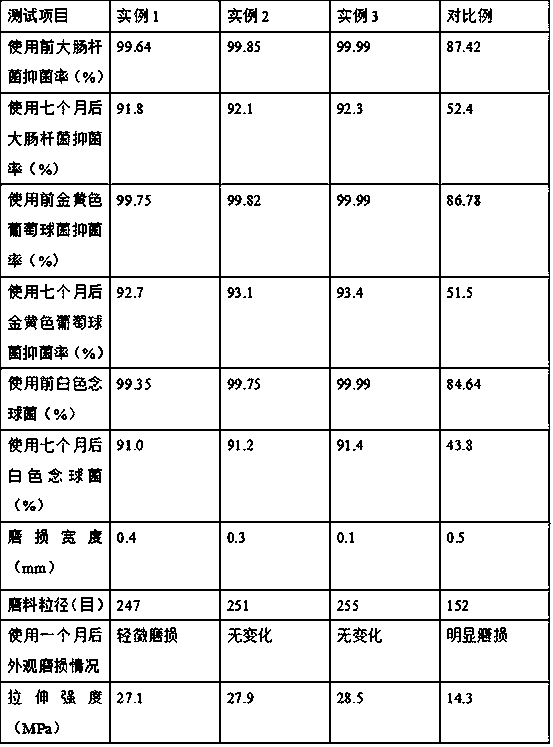

Examples

example 1

[0023]Put nitrile rubber, fluorosilicone rubber and sulfur into a mixer at a mass ratio of 3:2:1, and mix for 1 hour at a temperature of 120°C to obtain a self-made vulcanized mixed rubber; weigh 28g of a particle size of 55nm Pour the superfine alumina powder into a beaker with 4mL polyethylene glycol and 65mL deionized water and mix and stir for 8min to obtain a self-made superfine alumina aqueous dispersion. The aluminum water dispersion, deionized water and absolute ethanol were mixed and placed in a four-necked flask equipped with a condenser, a thermometer and a stirrer, stirred for 16 min, heated to 65 ° C, and then added to the four-necked flask with 10 mL of 35 % silver nitrate solution and 1mL silane coupling agent KH-570, continue to heat and stir for 24min, filter and remove the filtrate to obtain a filter residue, wash the filter residue twice with deionized water, and finally put it in an oven and dry it at a temperature of 55°C 35min, cooling and discharging to ...

example 2

[0025] Put nitrile rubber, fluorosilicone rubber and sulfur into the mixer according to the mass ratio of 3:2:1, and mix for 2 hours at a temperature of 140°C to obtain a self-made vulcanized mixed rubber; weigh 30g of the particle size of 60nm Pour the superfine alumina powder into a beaker with 5mL polyethylene glycol and 70mL deionized water and mix and stir for 9 minutes to obtain a self-made superfine alumina aqueous dispersion. The aluminum water dispersion, deionized water and absolute ethanol were mixed and placed in a four-necked flask equipped with a condenser, a thermometer and a stirrer, stirred for 18 min, heated to 70°C, and then added to the four-necked flask 11mL with a mass fraction of 35 % silver nitrate solution and 2mL silane coupling agent KH-570, continue to heat and stir for 28min, filter and remove the filtrate to obtain a filter residue, wash the filter residue 3 times with deionized water, and finally put it in an oven and dry it at a temperature of 65...

example 3

[0027] Put nitrile rubber, fluorosilicone rubber and sulfur into the mixer according to the mass ratio of 3:2:1, and mix for 3 hours at a temperature of 160°C to obtain a self-made vulcanized mixed rubber; weigh 32g with a particle size of 65nm Pour the superfine alumina powder into a beaker with 6mL polyethylene glycol and 75mL deionized water and mix and stir for 10min to obtain a self-made superfine alumina aqueous dispersion. The aluminum water dispersion, deionized water and absolute ethanol were mixed and placed in a four-necked flask equipped with a condenser, a thermometer and a stirrer, stirred for 20 min, heated to 75°C, and then added to the four-necked flask 12mL with a mass fraction of 35 % silver nitrate solution and 3mL silane coupling agent KH-570, continue to heat and stir for 32min, filter and remove the filtrate to obtain a filter residue, wash the filter residue 4 times with deionized water, and finally put it in an oven and dry it at a temperature of 75°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com