Method for improving extended wavelength gallium indium arsenide detector etching damage

A technology of indium gallium arsenide and detectors, which is applied in the field of infrared detectors to achieve the effects of reducing density, improving quality and reducing dark current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

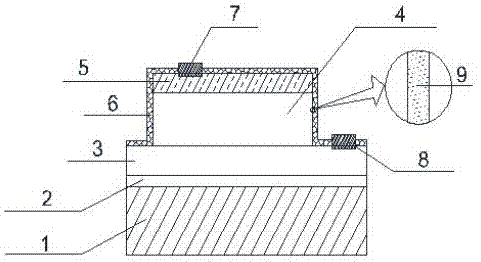

Image

Examples

Embodiment 1

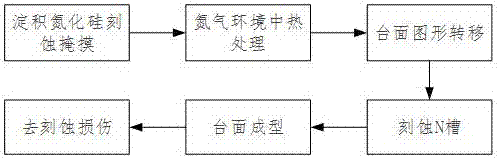

[0030] 1. Deposit silicon nitride etching mask, using plasma enhanced chemical vapor deposition (PECVD) technology to deposit silicon nitride etching mask with a thickness of 600±20nm, the substrate temperature is 330℃±10℃, radio frequency (RF ) power is 40W;

[0031] 2. Heat treatment in a nitrogen environment, put the sample that has deposited silicon nitride etching mask 1 into a rapid thermal annealing furnace, maintain a nitrogen flow rate of 5L / min, fill the annealing furnace with nitrogen for 30s before starting heating, and then The heat treatment is carried out by heating in a nitrogen atmosphere, and the heat treatment conditions are: the temperature is 420°C, and the time is 60s.

[0032] 3. Mesa pattern transfer, the heat-treated sample is subjected to photolithography, the photoresist is AZ1500, and after the photolithography is completed, an ICP etching machine is used to etch the silicon nitride etching mask grown on the epitaxial wafer to complete the patter...

Embodiment 2

[0037] 1. Deposit silicon nitride etching mask, using plasma enhanced chemical vapor deposition (PECVD) technology to deposit silicon nitride etching mask with a thickness of 600±20nm, the substrate temperature is 330±10°C, radio frequency (RF) The power is 40W;

[0038]2. Heat treatment in a nitrogen environment, put the sample that has deposited silicon nitride etching mask 1 into a rapid thermal annealing furnace, maintain a nitrogen flow rate of 5L / min, fill the annealing furnace with nitrogen for 30s before starting heating, and then The heat treatment is carried out by heating in a nitrogen atmosphere, and the heat treatment conditions are: the temperature is 420°C, and the time is 60s.

[0039] 3. Mesa pattern transfer, the heat-treated sample is subjected to photolithography, the photoresist is AZ1500, and after the photolithography is completed, an ICP etching machine is used to etch the silicon nitride etching mask grown on the epitaxial wafer to complete the patt...

Embodiment 3

[0044] 1. Deposit silicon nitride etching mask, using plasma enhanced chemical vapor deposition (PECVD) technology to deposit silicon nitride etching mask with a thickness of 600±20nm, the substrate temperature is 330±10°C, radio frequency (RF) The power is 40W;

[0045] 2. Heat treatment in a nitrogen environment, put the deposited silicon nitride etching mask sample into a rapid thermal annealing furnace, maintain a nitrogen flow rate of 5L / min, fill the annealing furnace with nitrogen for 30s before starting heating, and then Heat treatment under nitrogen atmosphere, heat treatment conditions: temperature 420°C, time 60s.

[0046] 3. Mesa pattern transfer, the heat-treated sample is subjected to photolithography, the photoresist is AZ1500, and after the photolithography is completed, an ICP etching machine is used to etch the silicon nitride etching mask grown on the epitaxial wafer to complete the pattern transfer.

[0047] 4. N-groove etching is performed on the samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com