Preparation of nano fibre carrier for loading and slow releasing pharmaceutical and biologically active factor

A bioactive factor, nanofiber technology, used in fiber processing, drug delivery, spinning solution preparation, etc., can solve problems such as insufficient water volatility, easy protein inactivation, and failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

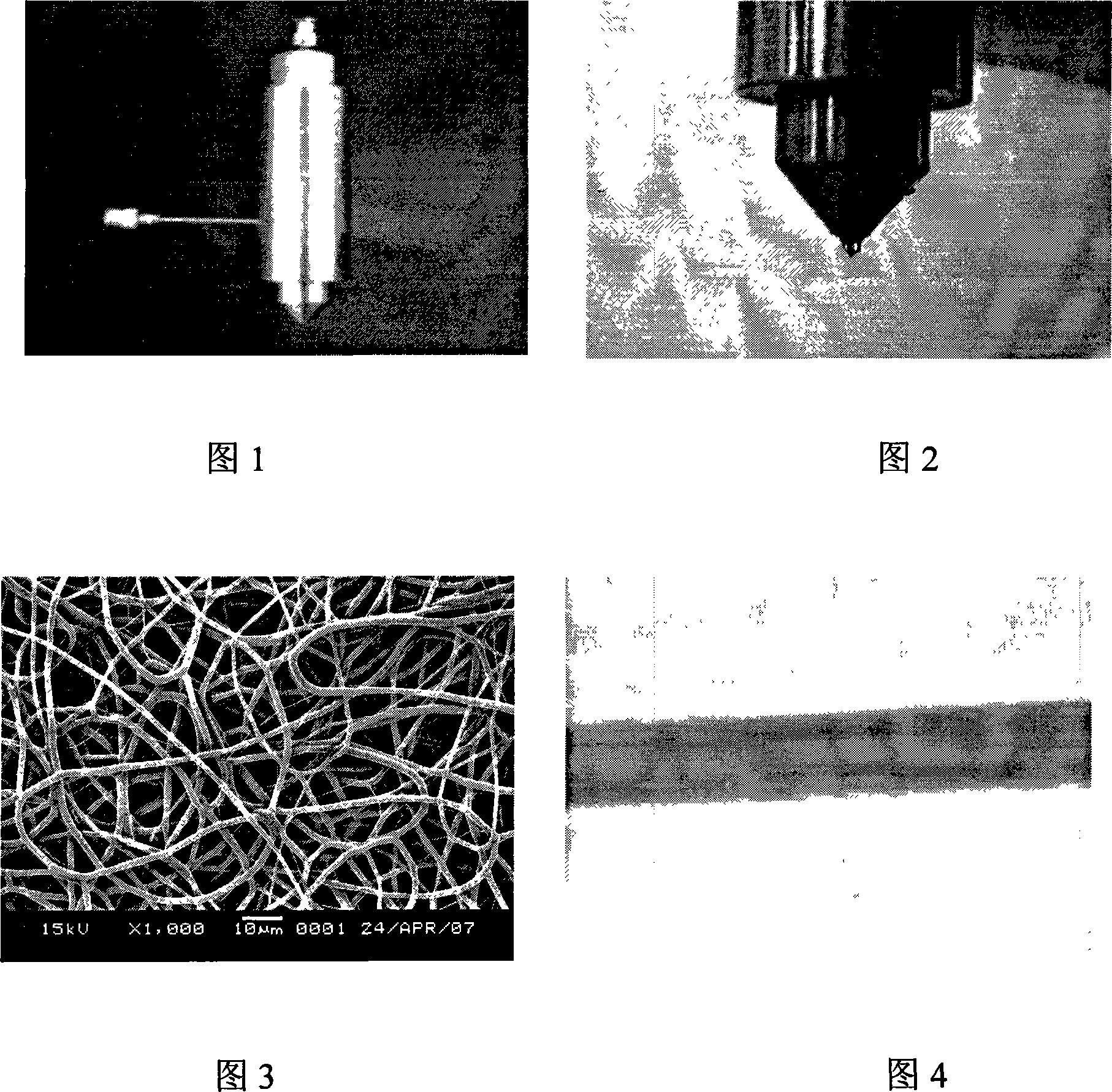

[0026] Weigh 0.3g gelatin, 0.3gBSA and 0.01mgNGF respectively with an electronic balance, and dissolve them in 10ml ultrapure water under aseptic conditions at the same time, stir and oscillate to dissolve completely to obtain the inner layer solution; electronic balance weighs 0.5g P( LLA-CL)[50:50], dissolved in 10ml of trifluoroethanol, stirred and oscillated until completely dissolved, to obtain the outer layer solution; coaxial electrospinning, set the flow rate of the inner layer solution to 0.2ml / h, and spin The diameter of the head is 0.9mm, the flow rate of the outer layer solution is 0.5ml / h, and the diameter of the spinneret is 1.2mm; 15kv is applied, and the distance between the nozzle and the receiving plate is 8cm, and the spinning is carried out; a "shell-core" structure nanometer with a diameter of about 200mm is obtained. The fiber, wherein the core layer is about 80 nanometers.

Embodiment 2

[0028] Take by weighing 0.3g gelatin, 0.3gBSA and 0.01mgVEGF respectively with an electronic balance, and dissolve it in 10ml ultrapure water simultaneously under aseptic conditions, stir and oscillate to dissolve completely to obtain the inner layer solution; electronic balance weighs 0.5g P( LLA-CL)[50:50], dissolved in 10ml of trifluoroethanol, stirred and oscillated until completely dissolved, to obtain the outer layer solution; coaxial electrospinning, set the flow rate of the inner layer solution to 0.2ml / h, and spin The diameter of the head is 0.9mm, the flow rate of the outer layer solution is 0.5ml / h, and the diameter of the spinneret is 1.2mm; 15kv is applied, and the distance between the nozzle and the receiving plate is 8cm, and the spinning is carried out; a "shell-core" structure nanometer with a diameter of about 200mm is obtained. The fiber, wherein the core layer is about 80 nanometers.

Embodiment 3

[0030] Weigh 0.3g gelatin, 0.3gBSA and 0.1mg heparin with an electronic balance, and dissolve them in 10ml ultrapure water at the same time under sterile conditions, stir and oscillate to dissolve completely to obtain the inner layer solution; weigh 0.5g with an electronic balance P(LLA-CL)[50:50], dissolved in 10ml of trifluoroethanol, stirred and oscillated until completely dissolved to obtain the outer layer solution; coaxial electrospinning, set the flow rate of the inner layer solution to 0.3ml / h, The diameter of the spinneret is 0.9mm, the flow rate of the outer layer solution is 0.7ml / h, and the diameter of the spinneret is 1.2mm; 20kv is applied, and the distance between the nozzle and the receiving plate is 8cm, and the spinning is carried out; a "shell-core" with a diameter of about 220nm is obtained Structural nanofibers, wherein the core layer is about 100 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com