Aging-resistant easy-welding thermoplastic polyolefin waterproof roll material and preparation method thereof

A thermoplastic polyolefin and waterproof membrane technology, which is applied in the field of anti-aging and easy-to-weld thermoplastic polyolefin waterproof membrane and its preparation, to achieve the effects of good waterproof performance, good construction performance and easy welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

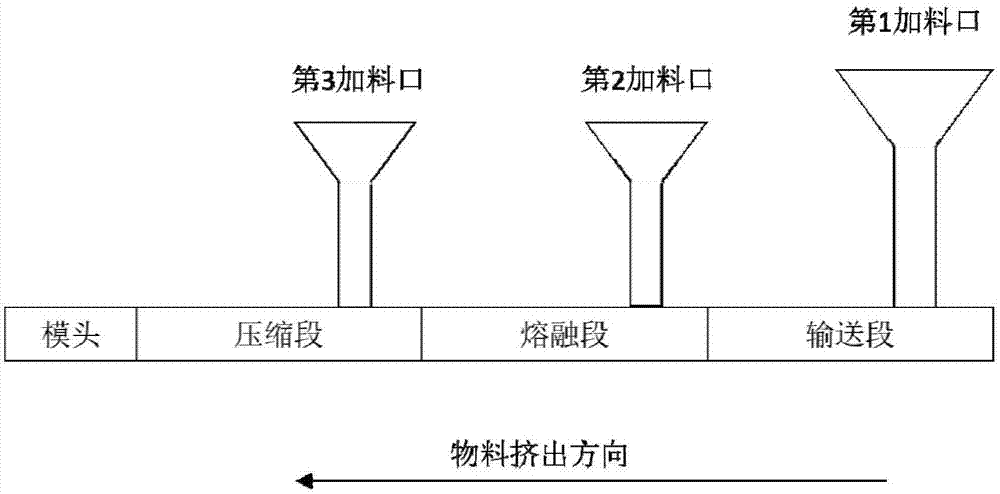

[0042] Take 50 parts of polyolefin thermoplastic elastomer, 30 parts of polypropylene, and 20 parts of filler masterbatch, and use it as a benchmark for the mass fraction of other materials, mix it in a high-speed mixer (500r / min) for 15 minutes, and set the twin-screw extruder The temperature is 200°C, and the above-mentioned uniformly mixed materials are put into the first feeding port, 0.15 parts of light stabilizer, 1.5 parts of rutile titanium dioxide, and 0.1 part of antioxidant are put into the second feeding port, 0.15 parts of light stabilizer, rutile 1.5 parts of titanium dioxide and 0.1 part of antioxidant were put into the third feeding port, and elliptical particles were obtained through extrusion, granulation and dicing. In the second step, the elliptical particles are put into a sheet material extruder, and the thermoplastic polyolefin waterproof membrane of Example 1 is obtained through extrusion, calendering, tempering, traction, and winding.

Embodiment 2

[0044]Take 60 parts of polyolefin thermoplastic elastomer, 30 parts of polypropylene, and 10 parts of filler masterbatch, and use it as a benchmark for the mass fraction of other materials, mix it in a high-speed mixer (500r / min) for 15 minutes, and set the twin-screw extruder The temperature is 200°C, and the above-mentioned uniformly mixed materials are put into the first feeding port, 0.15 parts of light stabilizer, 1.5 parts of rutile titanium dioxide, and 0.1 part of antioxidant are put into the second feeding port, 0.15 parts of light stabilizer, rutile 1.5 parts of titanium dioxide and 0.1 part of antioxidant were put into the third feeding port, and elliptical particles were obtained through extrusion, granulation and dicing. In the second step, the elliptical particles are put into a sheet material extruder, and the thermoplastic polyolefin waterproof membrane of Example 2 is obtained through extrusion, calendering, tempering, traction, and winding.

Embodiment 3

[0046] Take 60 parts of polyolefin thermoplastic elastomer, 30 parts of polypropylene, and 10 parts of filler masterbatch, and use it as a benchmark for the mass fraction of other materials, mix it in a high-speed mixer (500r / min) for 15 minutes, and set the twin-screw extruder The temperature is 200°C, and the above-mentioned uniformly mixed materials are put into the first feeding port, 0.25 parts of light stabilizer, 2 parts of rutile titanium dioxide, and 0.05 parts of antioxidant are put into the second feeding port, 0.05 parts of light stabilizer, rutile 1 part of titanium dioxide and 0.15 part of antioxidant were put into the third feeding port, and elliptical particles were obtained through extrusion, granulation and dicing. In the second step, the elliptical particles are put into a sheet material extruder, and the thermoplastic polyolefin waterproof membrane of Example 3 is obtained through extrusion, calendering, tempering, traction, and winding.

[0047] attached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com