Low whitening, oil bath resistant, low temperature toughening and glass fiber reinforced polypropylene material

A technology of polypropylene material and copolymerized polypropylene, which is applied in low-whitening, glass-fiber-reinforced polypropylene materials, low-temperature toughening, and oil-bath-resistant fields. problems, to achieve the effect of improving stress whitening resistance, oil resistance and low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the described low-whitening, oil-bath-resistant, low-temperature toughening, and glass fiber-reinforced polypropylene material comprises the following steps: copolymerizing polypropylene, PPR, POE, grafted polypropylene, Vistamaxx, synthetic mica powder, processing aid The agent is evenly mixed, and then fed from the main feeding port of the extruder, and the glass fiber is fed into the screw barrel of the extruder through a side feeding scale; the raw materials are melted, extruded, and granulated in the extruder to obtain the above-mentioned Low blush, oil bath resistant, low temperature toughened, glass fiber reinforced polypropylene material.

[0035] The extruder is a twin-screw extruder. The melting temperature in the melting step is 180-250°C. The processing conditions of the melting step are as follows: the temperature in the first zone is 170-190°C, the temperature in the second zone is 200-220°C, the temperature in the third zone is ...

Embodiment 1

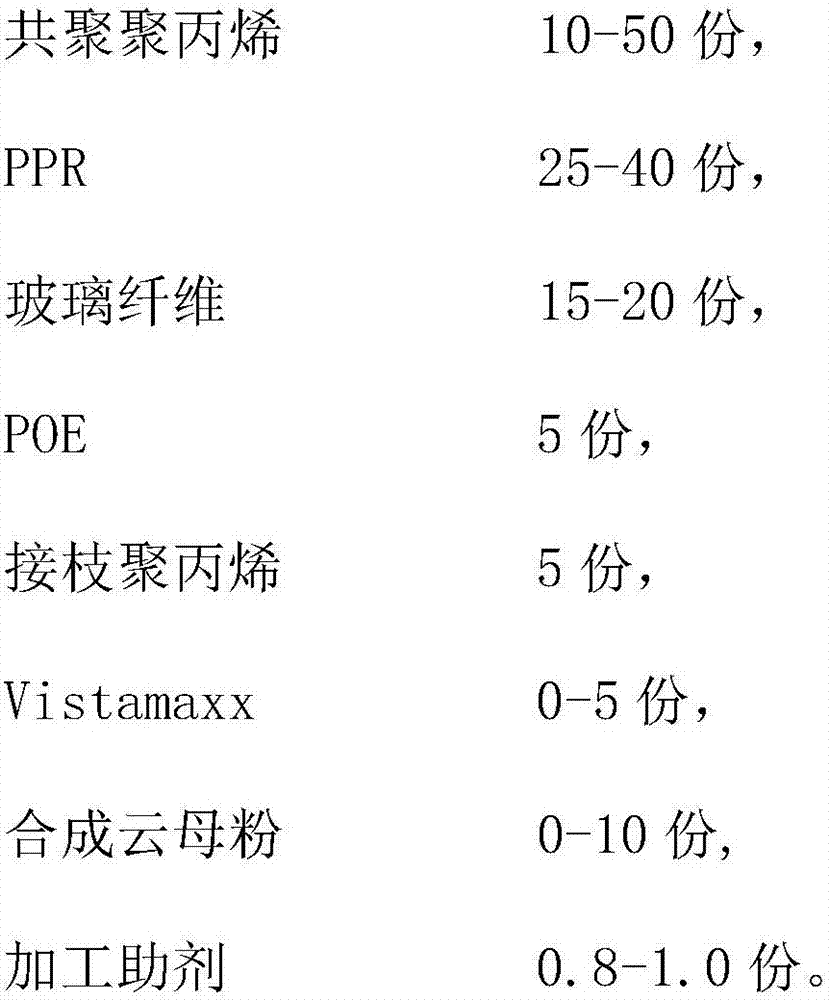

[0037] In the low-whitening, oil-bath-resistant, low-temperature-toughened, glass-fiber-reinforced polypropylene material: the processing aids include antioxidants, lubricants, and antisticking agents, and the antioxidants are antioxidants 1010 and antioxidant 168, wherein antioxidant 1010 and antioxidant 168 are compounded according to a mass ratio of 1:1, the lubricant is polyethylene wax lubricant, and the anti-sticking agent is FX-5920A (tetrafluoroethylene processing aid), the distribution ratio of each component is shown in Table 1.

[0038]The preparation method of the described low-whitening, oil-bath-resistant, low-temperature toughened, and glass fiber-reinforced polypropylene material comprises the following steps: uniformly mixing copolymerized polypropylene, PPR, POE, grafted polypropylene, and processing aids, and then starting from The main feeding port of the extruder is fed, and the glass fiber is fed into the screw barrel of the extruder through the side feed...

Embodiment 2

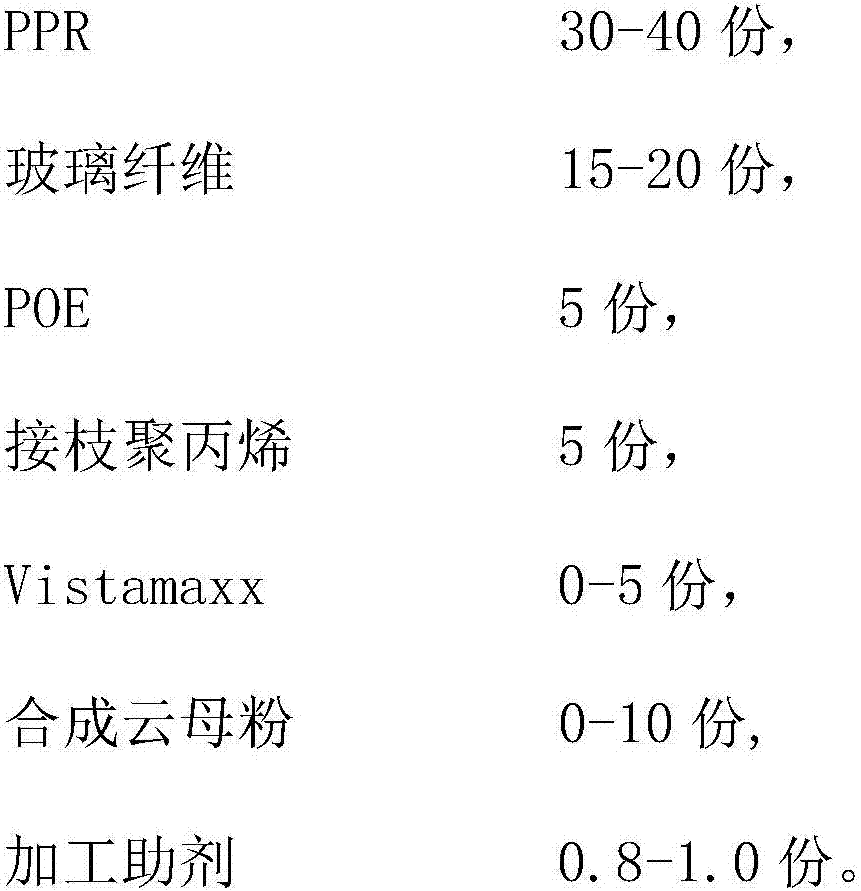

[0041] In the low-whitening, oil-bath-resistant, low-temperature-toughened, glass-fiber-reinforced polypropylene material: the processing aids include antioxidants, lubricants, and antisticking agents, and the antioxidants are antioxidants 1010 and antioxidant 168, wherein antioxidant 1010 and antioxidant 168 are compounded according to a mass ratio of 1:1, the lubricant is polyethylene wax lubricant, and the anti-sticking agent is FX-5920A (tetrafluoroethylene processing aid), the distribution ratio of each component is shown in Table 1.

[0042] The preparation method of the described low-whitening, oil-bath-resistant, low-temperature toughening, and glass fiber-reinforced polypropylene material comprises the steps of uniformly mixing copolymerized polypropylene, PPR, POE, grafted polypropylene, Vistamaxx, and processing aids, Then feed from the main feeding port of the extruder, and the glass fiber is fed into the screw barrel of the extruder through a side feeding scale; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com