Chemically-reinforced cover plate glass, and preparation method thereof

A cover glass and chemical technology, which is applied in the field of chemically strengthened cover glass and its preparation, can solve the problems of fewer production processes, inability to adapt to the requirements of use scenarios, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The method for preparing a chemically strengthened cover glass of the present disclosure limits the specific components and content range of the glass composition, and adopts a chemical strengthening process, so that the chemically strengthened cover glass prepared by the method has a higher surface stress And the larger thickness of the stress layer improves the surface scratch resistance of the chemically strengthened glass substrate, making it resistant to external forces such as dropping and abrasion, and the chemically strengthened cover glass has strong alkali resistance.

[0025] According to the present disclosure, SiO 2 It is an essential component of the glass skeleton, which can improve the degree of glass network connection, chemical resistance and mechanical strength of the glass. If the content is too high, it will increase the high-temperature viscosity of the glass and make it difficult to melt the glass. Therefore, the suitable SiO in this disclosure 2 ...

Embodiment 1

[0043] The components and contents of the glass composition used to prepare the cover glass in this example are shown in Table 1. Weigh the glass composition according to the weight and mix it well, melt it into molten glass in a furnace at 1550-1650°C, keep it warm for 8 hours, cool down the molten glass to the temperature required for molding, and place it in a tin bath Inner molding, heat preservation at 630°C for 1 hour for annealing treatment, to obtain cover glass, test the density, expansion coefficient, strain point, annealing point, softening point and alkali-resistant surface weight loss rate of the cover glass, the test results are listed in Table 1;

[0044] Among them, the density test is determined by the Archimedes method, and the unit is g / cm 3 ; The coefficient of linear thermal expansion is measured by a horizontal dilatometer, and the coefficient of linear thermal expansion (CTE) in the range of 50 to 350 °C is measured by ×10 -7 / °C said.

[0045] Put the...

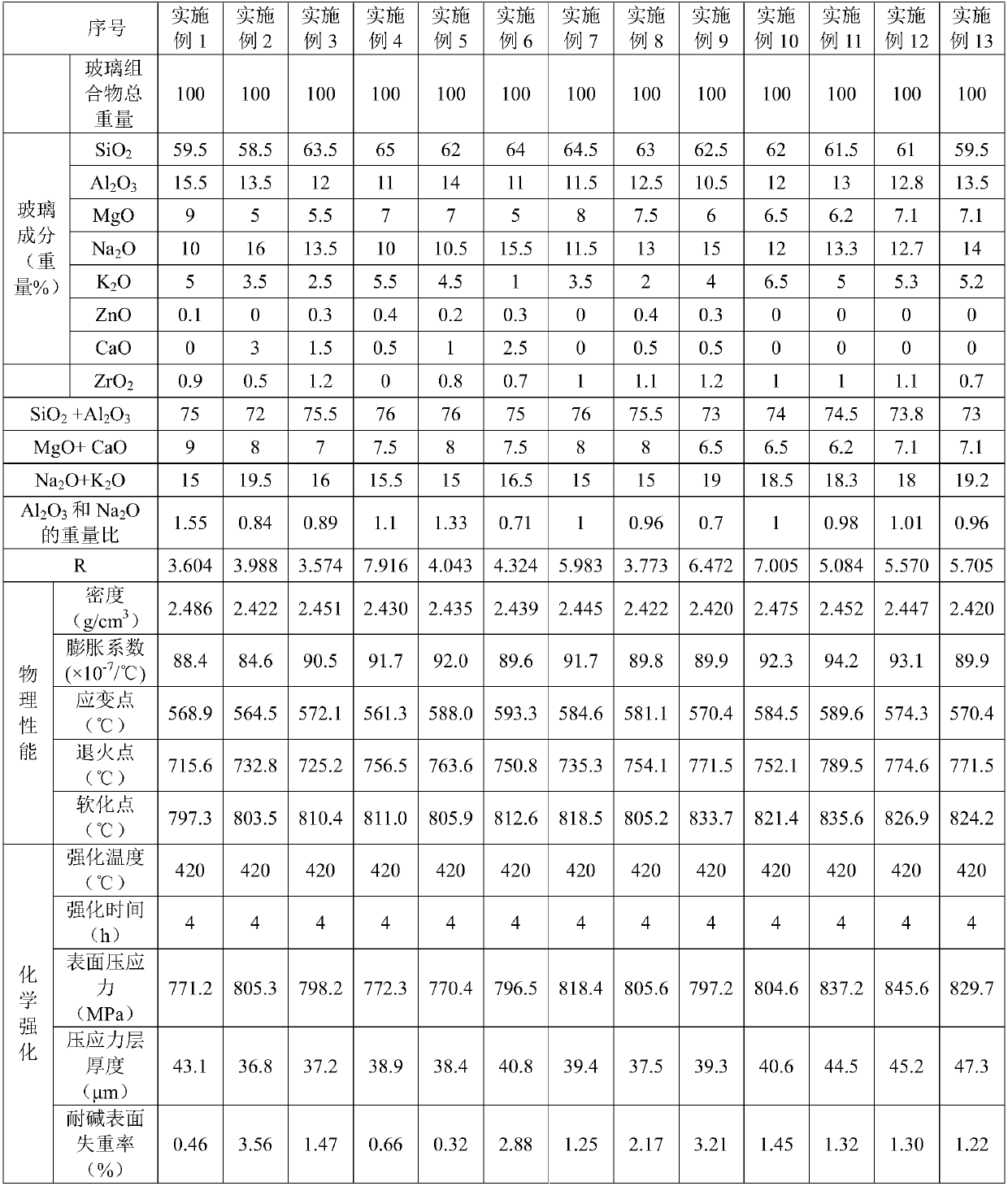

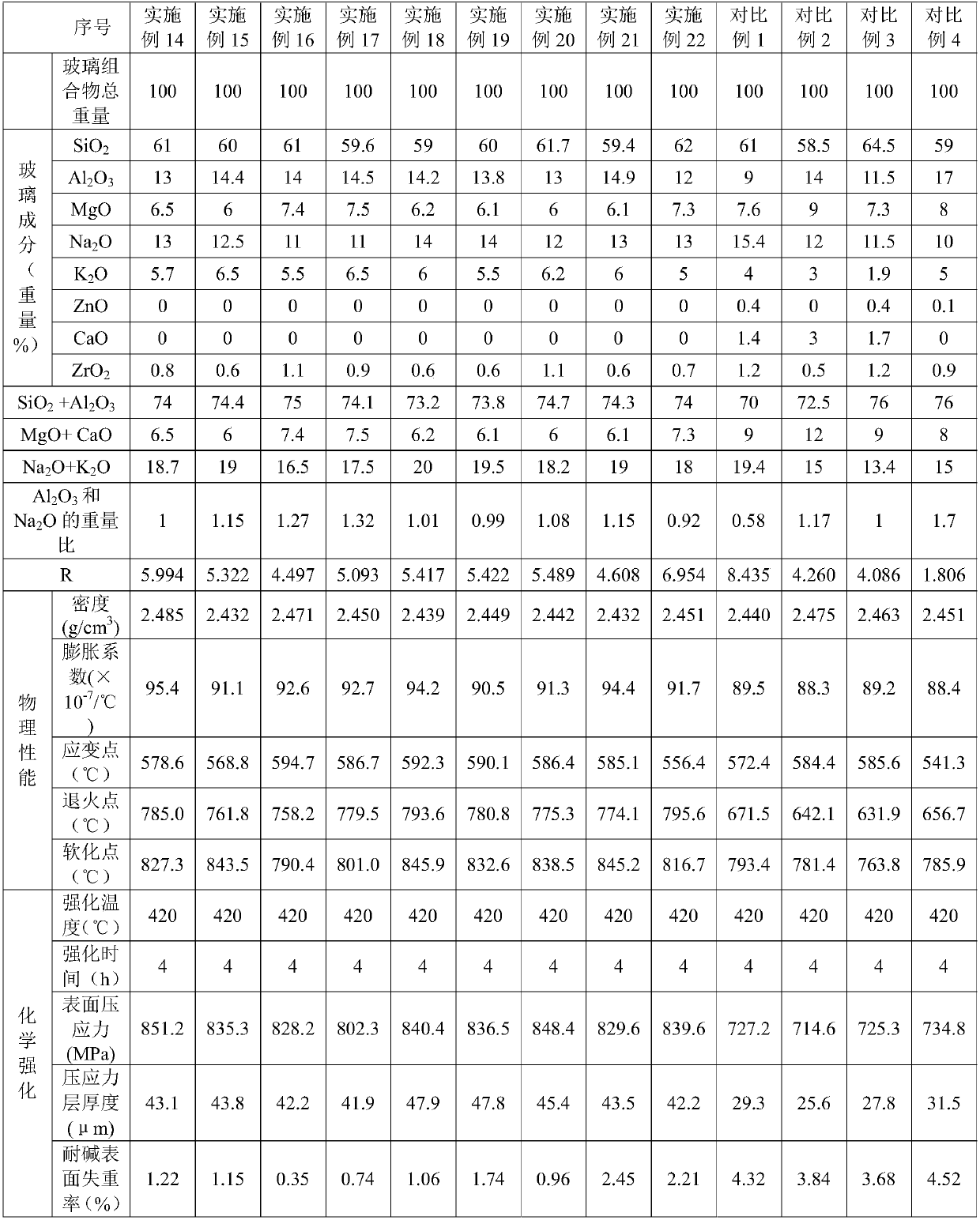

Embodiment 2~22 and comparative example 1~4

[0047]Examples 2-22 and Comparative Examples 1-4 respectively adopt the preparation method of Example 1, the difference is that the components and contents of the glass composition used to prepare the chemically strengthened cover glass are shown in Table 1 and Table 2 respectively Shown, the test results are listed in Table 1 and Table 2.

[0048] Table 1

[0049]

[0050] Table 2

[0051]

[0052] According to the data in Table 1 and Table 2, the comparison between Examples 1-22 and Comparative Example 1 shows that compared to SiO 2 +Al 2 o 3 The chemically strengthened cover glass prepared by the glass composition whose content range is different from the scope of the present disclosure, the chemically strengthened cover glass prepared by the method of the present disclosure has a large stress layer thickness and high surface stress; Examples 1-22 and From the comparison of Comparative Example 2, it can be seen that, compared with the chemically strengthened cover...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com